Product Description

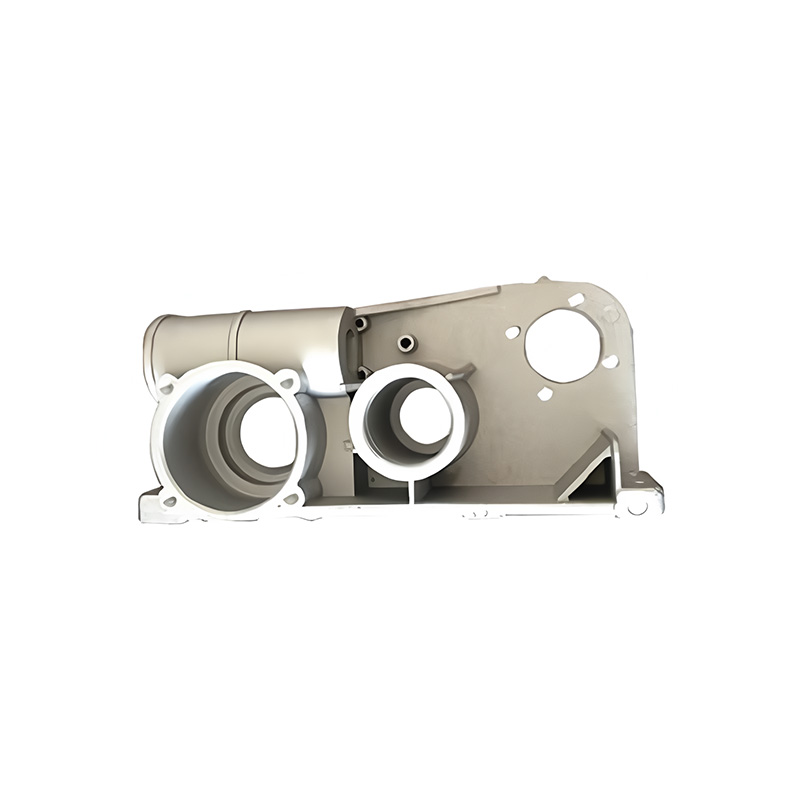

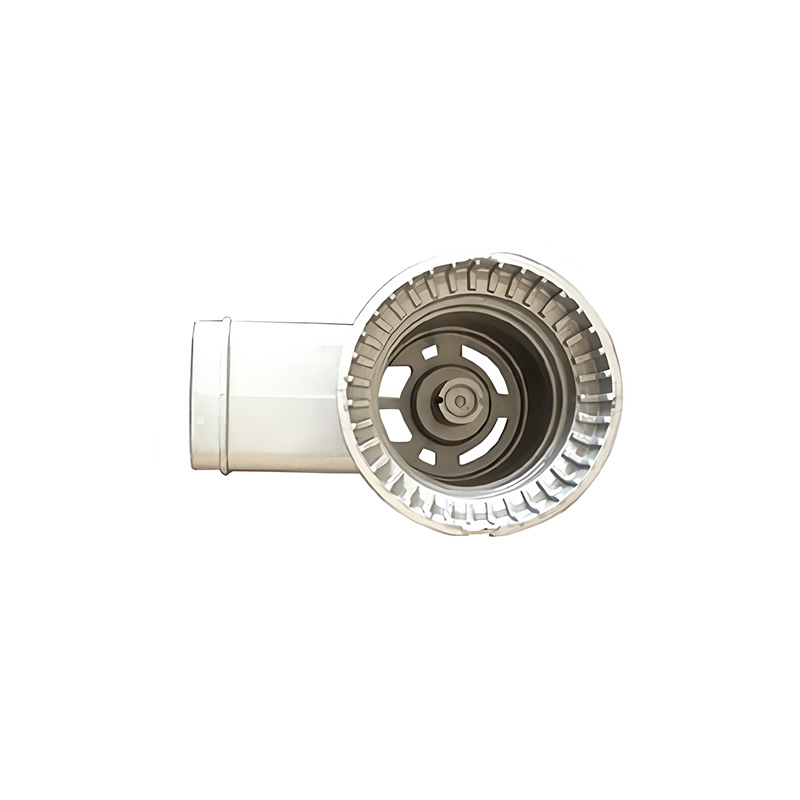

As a professional metal parts casting manufacturer, we focus on creating high-quality metal parts. Covering a variety of metal materials such as zinc metal, stainless steel, aluminum, etc., relying on advanced casting services and die-casting technology, from precision mold design to precise molding, we strictly control every production link. Whether it is complex structural parts or small parts, they can be precisely manufactured to meet the needs of different industries. We provide customers with customized solutions with superb technology and reliable quality.

Product parameters

| Process service | Die casting |

| Material | Steel, copper, aluminum, iron, alloy, etc. |

| Die Casting Machine Specification | 150T, 250T, 350T and 450T |

| Quote | According to your drawing(size, material, thickness, processing content and required technology, etc.) |

Custom Process

1.Contact customer service

2.Confirm specifications

3.Pay deposit

4.Arrange production

5.Quality inspection

6.Pay the final payment

7.Arrange delivery

8.Confirm receipt of goods

Process Type

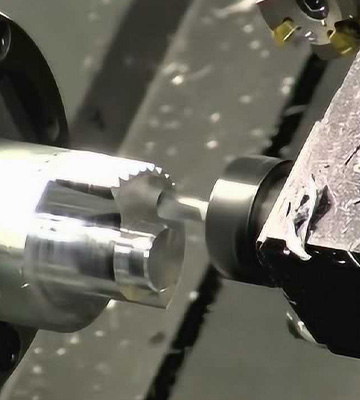

Turning process: The lathe drives the workpiece to rotate, and the tool performs feed motion to cut the workpiece. It mainly processes rotating parts with high precision and low roughness, and is widely used in the processing of shaft and disc parts.

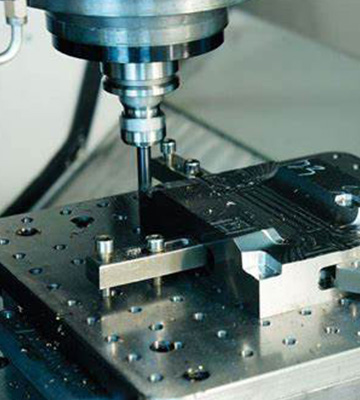

Milling process: The milling cutter is rotated and the workpiece is fed to cut the material. It can process various shapes such as planes and grooves with high precision. It is often used in machinery manufacturing, mold processing and other industries.

Pressure casting: Liquid or semi-liquid metal is pressed into the mold cavity at high speed under high pressure, and the casting is obtained after cooling and solidification. It can produce castings with complex shapes, with high efficiency, and is used in many industries to manufacture complex parts

Material

Iron

Aluminum alloy

Stainless steel

Aluminum

Processing capability

Pressure casting: Molten metal is injected into a mold under high pressure and quickly cooled to form. Suitable for producing thin-walled, complex-shaped zinc, aluminum, and magnesium alloy parts

Specialized in aluminum die casting for custom parts

There are specialized die casting machines 150T, 250T, 350T and 450T

There are post-casting finishing machines such as sandblasting machines, CNC milling machines, CNC lathes

Additional processes

Electroplating: Plating a layer of metal on the surface of the casting through the electroplating process, such as nickel plating, chrome plating, zinc plating, etc., can improve the wear resistance, corrosion resistance and decorativeness of the casting. For example, the shell of some precision instruments can be made more beautiful and have good protective performance through electroplating.