Product Description

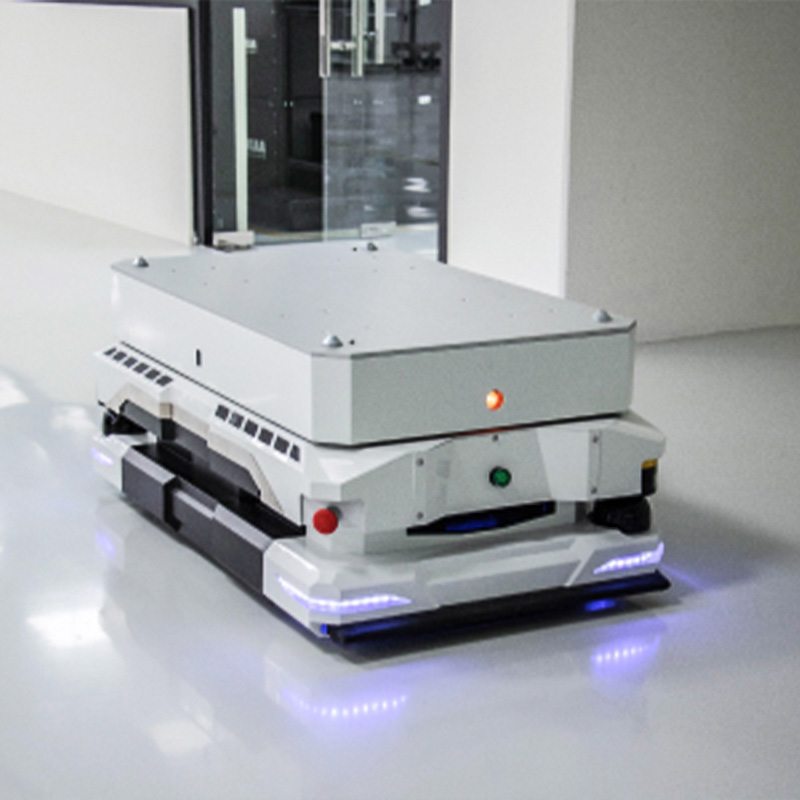

AUTONOMOUS MOBILE ROBOT

As a result of the increasing need for improved efficiency and higher productivity in the manufacturing industry, our AMR systems have been developed and implemented to ensure ease of implementation, reduced labor cost, and enhanced automation.

AMR robot bases are small, manoeuvrable and intelligent underride vehicles that operate flexibly and proactively in complex warehouse structures. These can be used as a stand-alone solution or integrated into existing warehouse management and control systems to suit the customer's requirements.

Product Features

Easy to change features

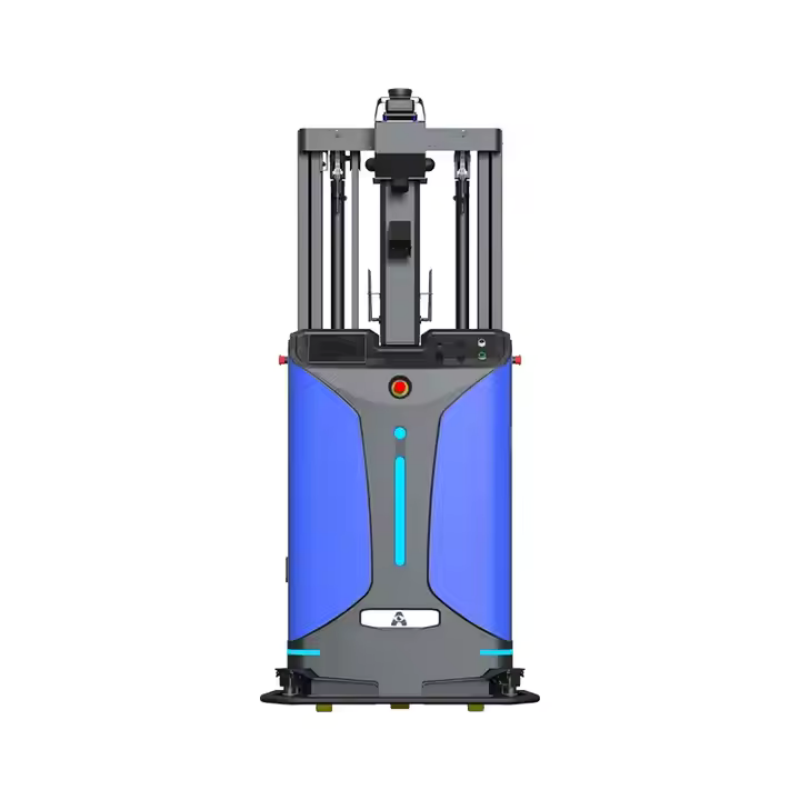

AMR and Smart tools. AMR is the base that can be moved flexibly according to the digital map and Smart tool is the upper function that can be changed arbitrarily based on usage requirements.

3 Class safety system

AMR achieves a very high level of safety with SICK's laser sensor, 3D deep camera and collision sensor. The sensors are programmed to be combined with each other very flexibly.

Flexible Shipping

The process of transporting goods in the factory is set up on the server management software or the operation panels by the touch screen feature, which is very flexible to easily change the plan for the user.

Application Cases

COMPREHENSIVE SOLUTIONS FOR MANUFACTURING

As a manufacturer, Phenikaa-X comprehensively meets the needs of MASS CUSTOMIZATION with robots in automatic transport, towing, and lifting in factories and warehouses, helping to INCREASE efficiency and REDUCE costs for our customers.

Surveying, consulting, supplying, and deploying optimized robots within the customer' s existing space and facilities;

Integrating robot solutions with the customer's existing management software systems;

Upgrading/renewing AGV/AMR robots to meet new customer demands in the future;

Providing fast maintenance and warranty services from the manufacturer to minimize production downtime for customers.

There are many varieties of AMRs designed specifically to reduce travel time associated with picking. This is accomplished by reducing picker travel time by bringing product to the picker.

Different models come equipped with a variety of handling technologies. From conveyor rollers to tilt trays and cross belt systems, AMRs are equipped for a wide range of sortation solutions including: High-speed parcel sortation; Returns handling; Short-term sortation.

Technical Parameter

Size | 1.1m x 0.64m x 0.283m |

Max Speed | 0.7m/s |

Max Payload | 250kg |

Battery Voltage | 24VDC |

Charging Time | 4hours |

Connect | Wifi/Ethernet |

FAQ

What mode of transportation do you usually use?

We mainly use three modes of transportation: sea transportation, air transportation and express delivery. For large quantities of goods, it is generally recommended to choose sea transportation, which is relatively cheap; for urgent orders or small quantities of high-value goods, air transportation or express delivery will be more suitable.

How long does it take from ordering to delivery?

In general, the delivery time of conventional products is about 30 days after the order is placed. If it is a customized product, the delivery time may be extended to 50 days. The specific time will be determined according to the specific circumstances of the order.

How long is the warranty period of the product?

The warranty period of our products is generally 1 year, calculated from the date of qualified acceptance of the goods. During the warranty period, if there is a quality problem with the product, we will provide free repair or replacement service.

If there is a problem with the product during use, how to carry out after-sales repair?

If there is a problem with the product, you can first contact our customer service staff and provide detailed information and problem description of the product. We will arrange professional technicians for remote guidance.