Product Description

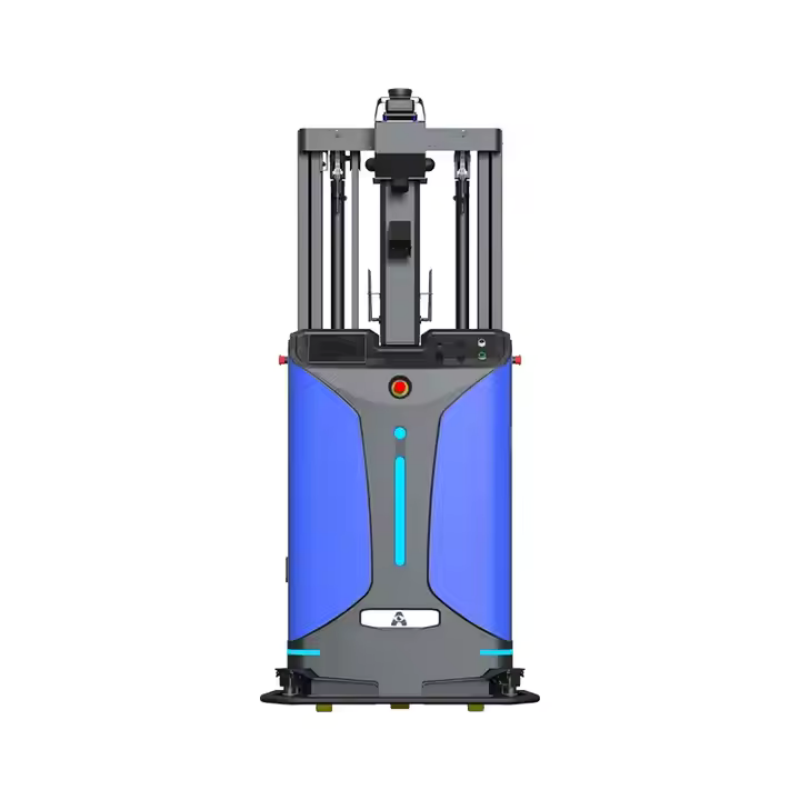

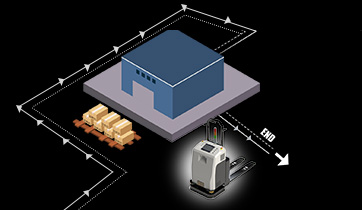

The APM Pallet Mover is the most advanced automated guided vehicle designed to transport heavy loads on pallets with high safety and efficiency. Combining advanced features and modern technology, the Pallet Mover meets all transportation needs in modern industrial environments.

The Pallet Mover is trusted by manufacturing plants in Vietnam. The deployment of Pallet Mover at SEVT has brought exceptional efficiency in goods transportation, enhancing productivity and ensuring maximum safety during production processes.

Product Features

Navigation Control System

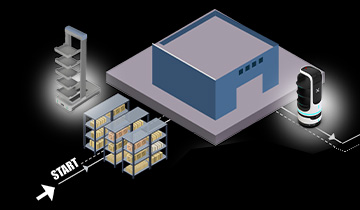

Navigation System: The Pallet Mover uses global and local positioning systems to navigate accurately in all environments.

Motor Control: Advanced motor control systems allow for smooth and precise movements, ensuring maximum operational efficiency.

Safety and Security

Sensors and Safety Devices: In addition to laser sensors, the Pallet Mover is equipped with ToF sensors and 3D cameras to detect and avoid obstacles.

User Account Management: Detailed guidelines for administrators on creating and managing user accounts, ensuring secure access and operation of the system.

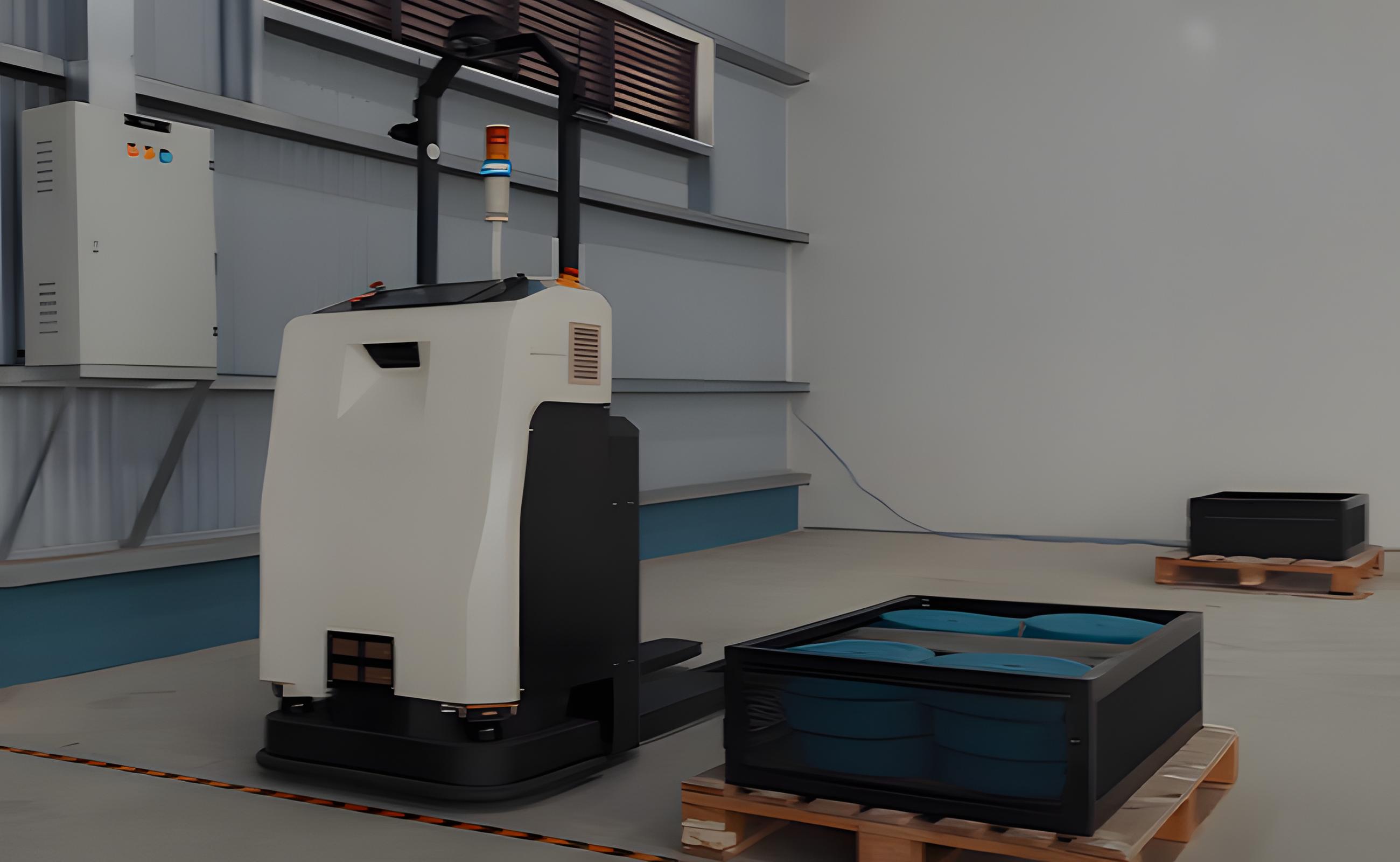

Application Cases

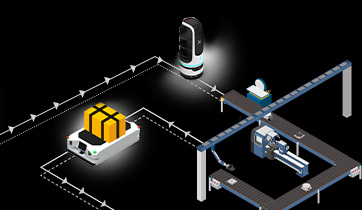

COMPREHENSIVE SOLUTIONS FOR MANUFACTURING

As a manufacturer, Phenikaa-X comprehensively meets the needs of MASS CUSTOMIZATION with robots in automatic transport, towing, and lifting in factories and warehouses, helping to INCREASE efficiency and REDUCE costs for our customers.

Surveying, consulting, supplying, and deploying optimized robots within the customer' s existing space and facilities;

Integrating Phenikaa-X robot solutions with the customer's existing management software systems;

Upgrading/renewing AGV/AMR robots to meet new customer demands in the future;

Providing fast maintenance and warranty services from the manufacturer to minimize production downtime for customers.

Technical Parameter

Size | 2.1m*0.8m*1.8m |

Max Speed | 1.2m/s |

Max Playload | 990kg |

Battery Voltage | 1.16kw/20ah |

Charging Time | 1.75h |

Working Time | 8h |

FAQ

What mode of transportation do you usually use?

We mainly use three modes of transportation: sea transportation, air transportation and express delivery. For large quantities of goods, it is generally recommended to choose sea transportation, which is relatively cheap; for urgent orders or small quantities of high-value goods, air transportation or express delivery will be more suitable.

How long does it take from ordering to delivery?

In general, the delivery time of conventional products is about 30 days after the order is placed. If it is a customized product, the delivery time may be extended to 50 days. The specific time will be determined according to the specific circumstances of the order.

How long is the warranty period of the product?

The warranty period of our products is generally 1 year, calculated from the date of qualified acceptance of the goods. During the warranty period, if there is a quality problem with the product, we will provide free repair or replacement service.

If there is a problem with the product during use, how to carry out after-sales repair?

If there is a problem with the product, you can first contact our customer service staff and provide detailed information and problem description of the product. We will arrange professional technicians for remote guidance.