Product Description

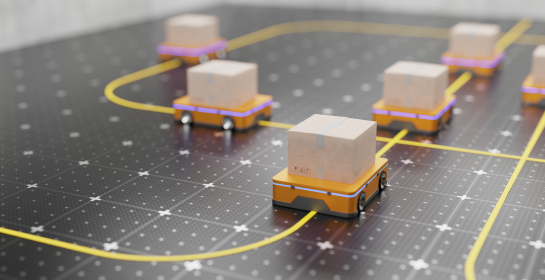

The Sparq Mini is a compact AGV designed for efficiency and reliability in material handling operations. It supports a payload of up to 200kg for towing and 150kg for direct loading, making it ideal for various industrial and warehouse applications. With its low-cost design, the Sparq Mini provides an affordable automation solution while maintaining high performance and safety standards.

Its compact size allows it to maneuver seamlessly in tight and confined spaces, making it a perfect fit for small warehouses, production lines, and retail environments. The flexibility of the AGV ensures that it can integrate smoothly into existing workflows without requiring major infrastructure modifications.

Product Features

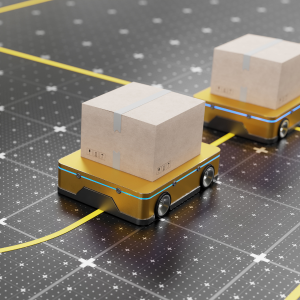

Compact and Agile Design

The Sparq Mini is designed to navigate through tight and confined spaces, making it ideal for small warehouses, factories, and retail environments. Its lightweight and low-profile structure allows it to operate efficiently without disrupting existing workflows.

Magnetic Line Following Navigation

Equipped with a precise magnetic line following system, the Sparq Mini ensures accurate and reliable movement along predefined paths. This feature minimizes navigation errors and enhances efficiency in automated material transport.

Advanced Safety Features

The AGV includes multiple safety mechanisms, such as an obstacle detection sensor, a bumper switch to halt movement upon contact, and an emergency stop button for quick manual intervention, ensuring safe operation in busy environments.

Product parameters

| Application | Industrial |

| Function | Towing, Hooking |

| Navigation method | Magnetic Strip Guidance |

| Payload | 200 kg (Tow) / 150 kg (Load) |

| Maximum Speed | 0.7 m/s |

| Running Time | 6 hours |

| Charging Time | 5 hours |

| Traveling Direction | Single Directional / Multiple Sequential Stop Point |

| Turning Radius | 0.9 m |

| Drive Method | Steered Differential |

Application Cases

Transporting Electronic Components in a Manufacturing Plant

The Sparq Mini is used in electronic component manufacturing plants to transport small parts such as circuit boards, processors, and semiconductors from the storage area to the production line, reducing errors caused by manual handling.

Moving Medications and Medical Supplies in Hospitals

The Sparq Mini can be used in hospitals to transport medications, medical equipment, and supplies from the pharmacy to different departments, such as emergency rooms, operating rooms, or patient wards, reducing the burden on nursing staff.

Automated Product Transport in Retail Stores

The Sparq Mini can be used in retail stores or supermarkets to automatically transport products to shelves, such as restocking items or removing out-of-stock goods for storage, reducing the workload on employees

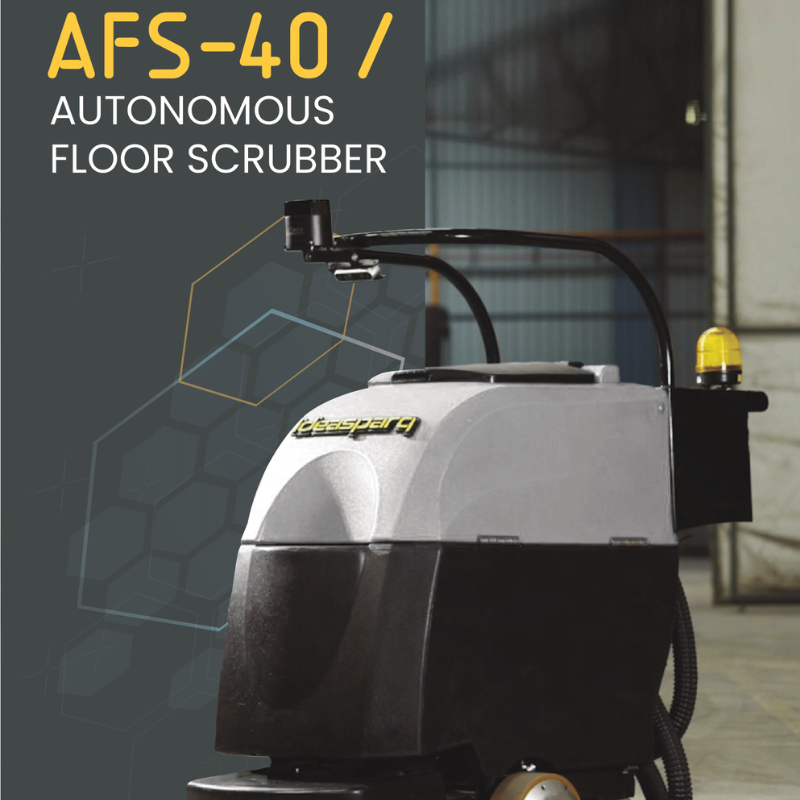

Company Information

Ideasparq Robotics Sdn. Bhd. is a company focused on developing advanced robotics and automation solutions for various industries, particularly in manufacturing, warehouse management, and cleaning services. Founded: Ideasparq was established in 2012 with the goal of developing robotics and automation technology to enhance operational efficiency and reduce errors in production. Headquarters: Located in Malaysia. Team Size: The company employs a professional team of experts in robotics, AI development, and research & development (R&D)Company Information: