Product Description

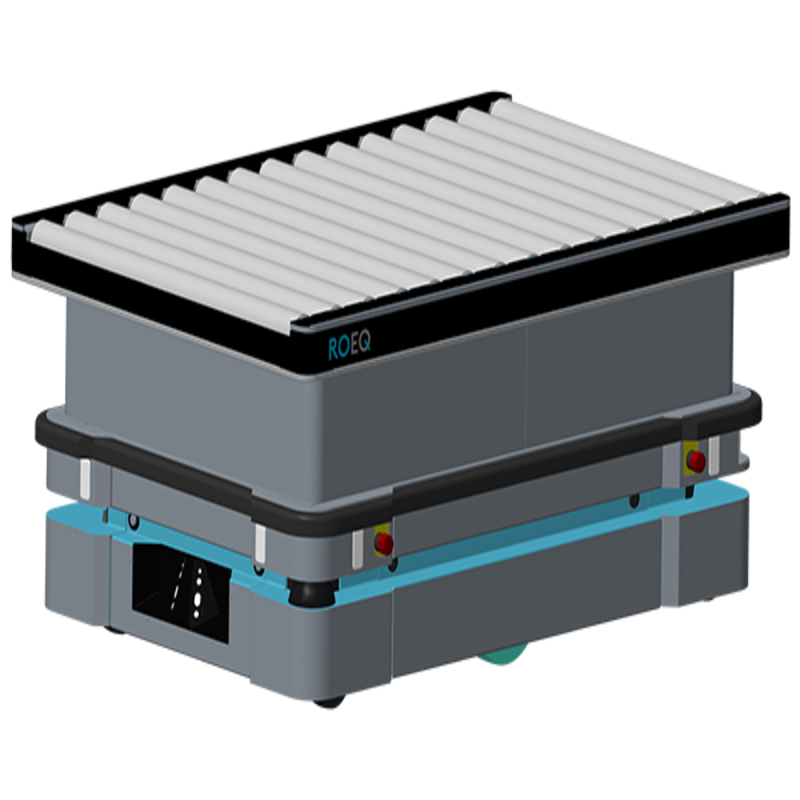

GR Roller Conveyor Autonomous Mobile Robot (AMR) systems is excellent in increasing the utility and flexibility of conveyor systems by being a mobile conveyor to serve multiple fixed conveyors. Fixed conveyor lines limit the flexibility of redeployment especially during product changes (high mix low volume). However, the GR AMRs allow easy adaptability extending the useful life of the investment. The Load Transfer AMR are ideally suited for transporting heavy and bulky pallets/items in warehouses, fulfilment and distribution centres. These AMRs provide optimum solutions for applications where space is at a premium, flexibility and scalability is a must and operational efficiency is imperative.

Product Features

Payload Capacity of 1500 kg:

The Smart Roller Conveyor can handle heavy and bulky loads with a payload capacity of up to 1500 kg, making it ideal for transporting large items, pallets, or materials in demanding environments such as warehouses and manufacturing floors.

Advanced Navigation Technology:

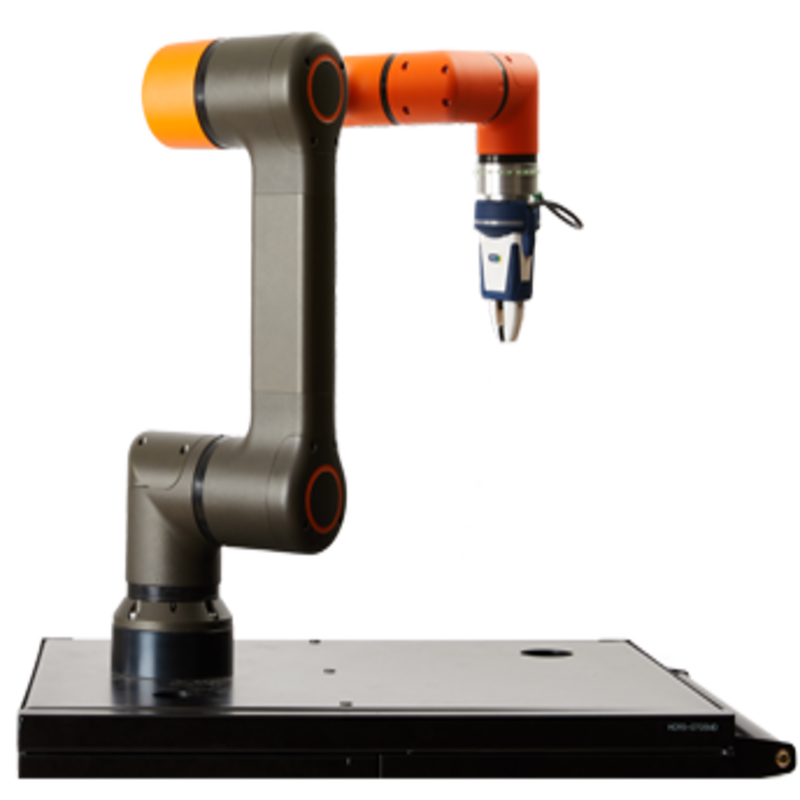

The system uses advanced navigation technology, including LIDAR and vision-based navigation, enabling precise movement and interaction with the environment. This ensures safe and efficient operation, particularly in dynamic settings with complex layouts or obstacles.

Product parameters

| Feature | Description |

| Payload Capacity | Supports a payload capacity of up to 1500 kg. |

| Fleet Management System | Allows operation and monitoring of a fleet of vehicles. |

| Scalable and Adaptable | Easily scalable and adaptable to meet changing operational needs. |

| Advanced Navigation Technology | Uses LIDAR and vision-based navigation for precise movement. |

| ERP/MES/WMS Integration | Can integrate with ERP, MES, and WMS systems for better operational coordination. |

| Conveyor Options | Can be fitted with either a roller or belt conveyor, based on needs. |

| Flexibility | Mobile conveyor system for multiple fixed conveyor lines. |

| Improved Operational Efficiency | Provides better material handling and transport in tight spaces. |

| Rugged Design | Conveyor system is designed to handle heavy and bulky loads. |

Application

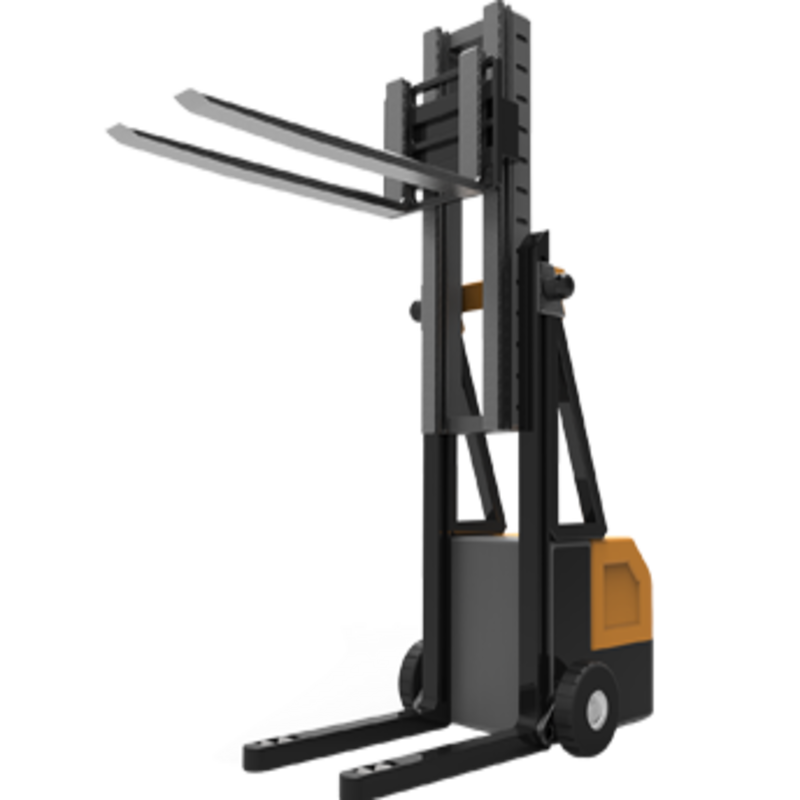

Warehouse and Distribution Centers:

Application: The Smart Roller Conveyor is ideal for transporting heavy and bulky pallets or items within warehouses and distribution centers. It can be used to connect different areas within the facility, moving goods between storage zones and picking stations. The mobile conveyor provides flexibility in handling varying material types, especially when the layout changes or product mixes fluctuate.

Benefit: It optimizes space utilization and improves operational efficiency by seamlessly integrating with existing fixed conveyor systems.

Fulfillment Centers:

Application: In fulfillment centers, where speed and accuracy are essential, the Smart Roller Conveyor transports items between different workstations or sorting areas. It adapts easily to high-volume, low-mix, or high-mix, low-volume environments, allowing workers to quickly move materials, reducing downtime and manual transport efforts.

Benefit: Enhances the speed and flexibility of order fulfillment, reduces bottlenecks, and supports the scalability of operations.

Manufacturing and Production Lines:

Application: The Smart Roller Conveyor is highly effective in manufacturing facilities where heavy materials or components need to be moved across production lines. It supports modular and adaptable conveyor systems, allowing easy integration into existing production workflows. The AMR can be fitted with a roller or belt conveyor, depending on the specific production needs.

Benefit: Increases productivity by automating material transport, ensuring smooth transitions between production stages and minimizing manual labor.