Product Description

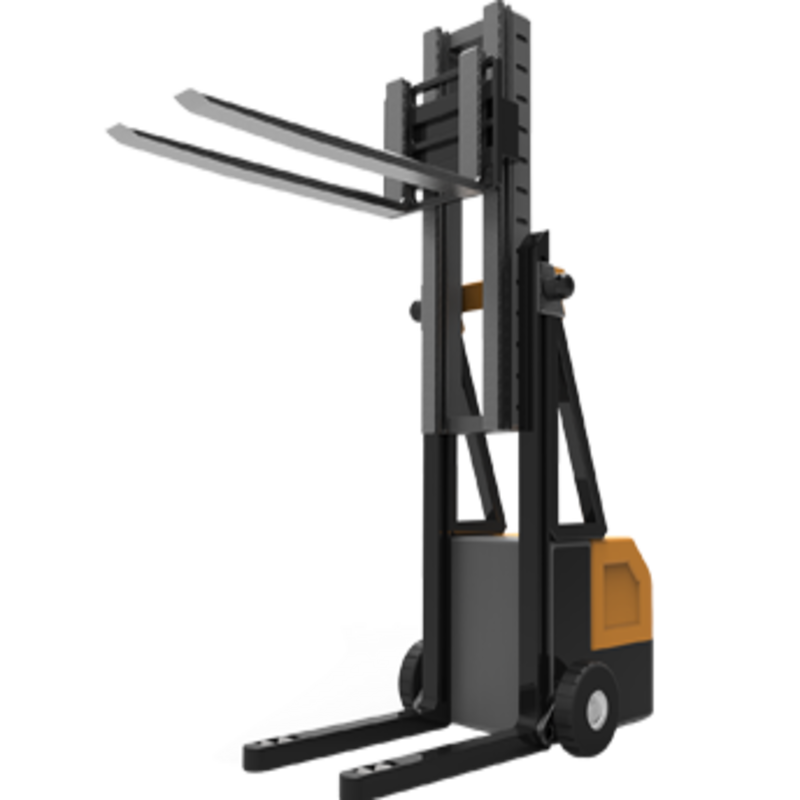

Golden Retriever Autonomous Lift Trucks offer optimum solutions for increased storage density. The AMR autonomously manouever around warehouses, picking up heavy loads, delivering it on time accurately and trackable by the system. Equipped with sensors, it is safe and is able to work in harsh environments, hot and cold, around the clock, 24 hours a day, 7 days a week. They can stack higher in existing warehouse without major modifications. An upgrade on the traditional forklift, The AMR is ideal for movement and stacking of goods in warehouses

Product Features

Space Optimization: The Autonomous Lift Trucks maximize warehouse space by allowing tighter row packing with minimal clearance, enabling higher stacking without major modifications to existing infrastructure.

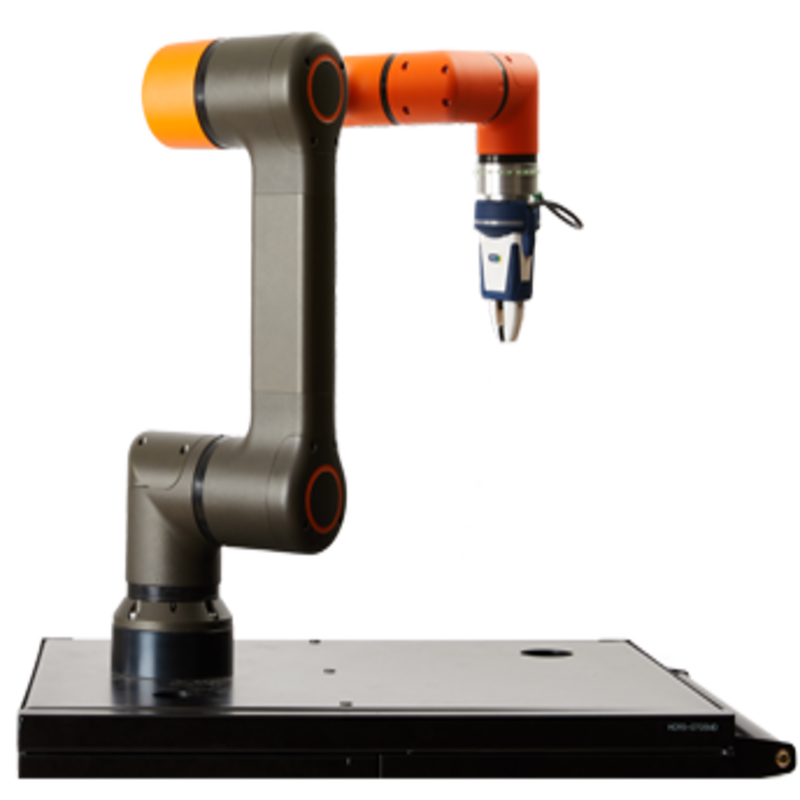

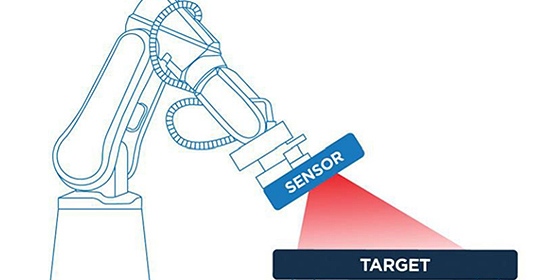

Safety and Reliability: Equipped with collision detection and avoidance sensors, these AMRs ensure safe operation in both indoor and outdoor environments, functioning 24/7 in harsh conditions.

More Details

Product parameters

Model | GR-100 | GR-200DLR | GR-500DLR | GR-20CP | GR-1500SRC | GR-1500UPS |

Weight | 80 kg | 145 kg | 240 kg | 120 kg | 800 kg | 250 kg |

Payload | 100 kg | 200 kg | 500 kg | 20 kg | 1500 kg | 1500 kg |

Dimensions (LxWxH) | 720 x 520 x 380 mm | 900 x 660 x 280 mm | 1100 x 750 x 300 mm | 900 x 650 x 2400 mm | 1830 x 1550 x 850 mm | 1080 x 1030 x 150 mm |

Speed | 1.2 m/s | 1.2 m/s | 1.2 m/s | 1.2 m/s | 1.0 m/s (1.2 m/s without load) | 1.2 m/s |

Charging Mode | Manual/Smart Dock | Opportunistic Charging | Opportunistic Charging | Opportunistic Charging | Opportunistic Charging | Opportunistic Charging |

Operation Duration | 8 hours | 8 hours | 8 hours | 8 hours | 8 hours | 8 hours |

Battery | 24V 30 Ah Lithium Ion (LFP) | 24V 40 Ah Lithium Ion (NMC) | 48V 60 Ah Lithium Ion (LFP) | 48V 300 Ah Lithium Iron (LFP) | 48V 60 Ah Lithium Iron (LFP) | 24V 50 Ah Sealed Lead Acid |

Navigation Method | Inertial Measurement Unit (IMU) aided by LIDAR, Magnetic Tape and/or Vision | Inertial Measurement Unit (IMU) aided by LIDAR, Magnetic Tape and/or Vision | Rail Guided | Rail Guided | Inertial Measurement Unit (IMU) aided by LIDAR, Magnetic Tape and/or Vision | Inertial Measurement Unit (IMU) aided by LIDAR, Magnetic Tape and/or Vision |

Fleet Management System | Web API for interface with ERP/MES/WMS | Web API for interface with ERP/MES/WMS | Web API for interface with ERP/MES/WMS | Web API for interface with ERP/MES/WMS | Web API for interface with ERP/MES/WMS | Web API for interface with ERP/MES/WMS |

Communication | Wi-Fi 2.4 GHz/5GHz, 802.11 a/b/g/n/ac | Wi-Fi 2.4 GHz/5GHz, 802.11 a/b/g/n/ac | Wi-Fi 2.4 GHz/5GHz, 802.11 a/b/g/n/ac | Wi-Fi 2.4 GHz/5GHz, 802.11 a/b/g/n/ac | Wi-Fi 2.4 GHz/5GHz, 802.11 a/b/g/n/ac | Wi-Fi 2.4 GHz/5GHz, 802.11 a/b/g/n/ac |

Front Safety | Scanning Laser | Scanning Laser | Scanning Laser | Bumper Sensor | Scanning Laser | Scanning Laser |

Rear Safety | None | None | None | None | Front and Rear Bumper | Front and Rear Bumper |

Application

Warehouse Material Handling: The AMR autonomously moves heavy loads and stacks goods, optimizing space and improving storage density in warehouses.

Efficient Stacking: It allows for higher stacking in existing warehouse setups without needing major modifications, making the most of available space.

Labor Reduction: The AMR performs repetitive and demanding tasks, reducing the need for human labor and allowing employees to focus on higher-value work.