Product Description

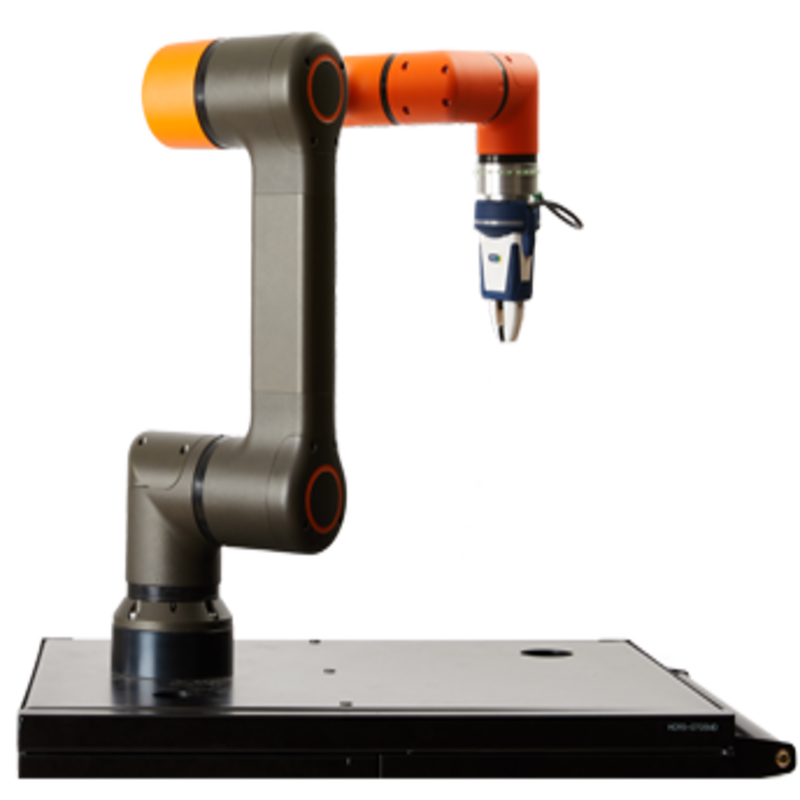

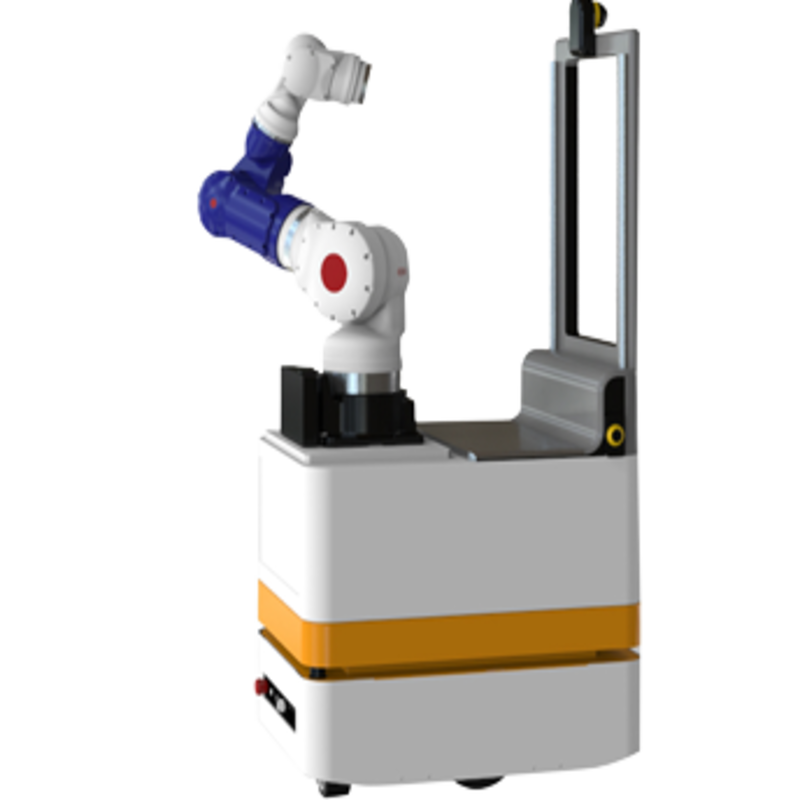

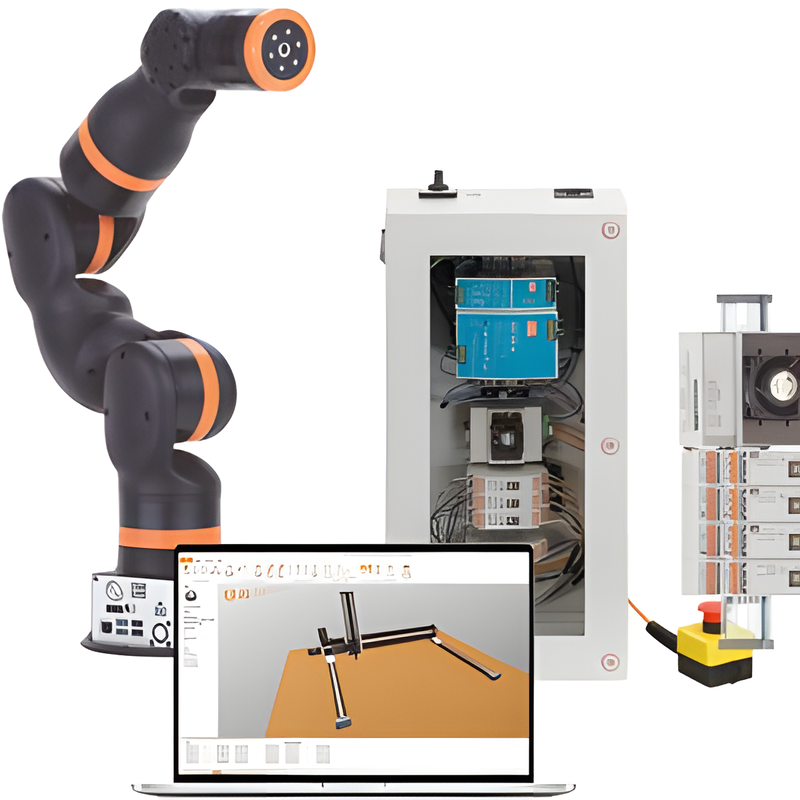

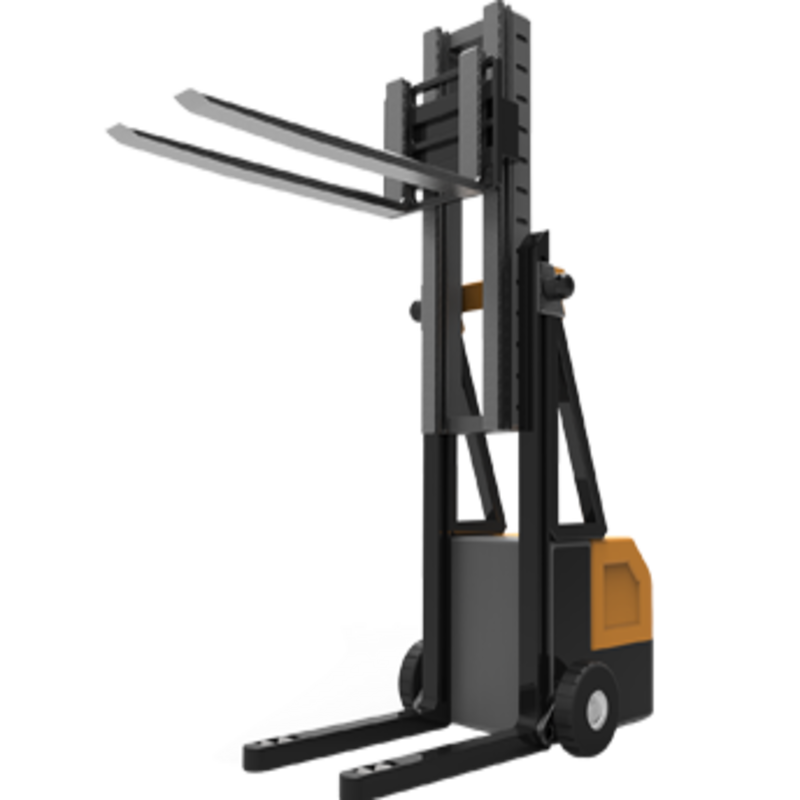

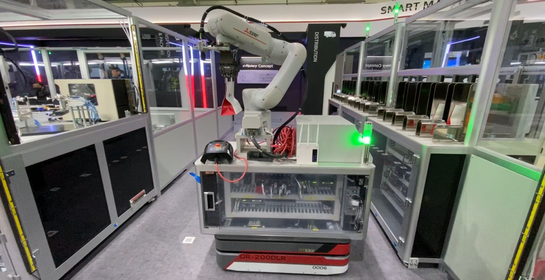

The GoldenRetriever (GR) Manipulator Autonomous Mobile Robot (AMR) Series is excellent in extending the utility and flexibility of a traditional robotic arm by providing a mobile base for it to autonomously serve multiple workstations. Combining the dexterity of a collaborative robot (cobot) arm with the mobility of the GR AMR, the Manipulator allows for multi-axis movement and can be of special use in tight places (0 turning radius). The AMR systems are ideally suited to perform tasks such as precise retrieval of small, delicate material or heavy items by placing it onto the body of AMR as well as machine tending and is mainly used in production floors. Safe to work with and flexible in adoption, it is collaborative and operates to complement and help human operators within the same workspace.

Product Features

Arm and Platform Payload Capacity: The GR Manipulator offers a 20kg arm payload capacity and a 500kg platform payload, making it versatile for handling both small and heavy items in various production environments.

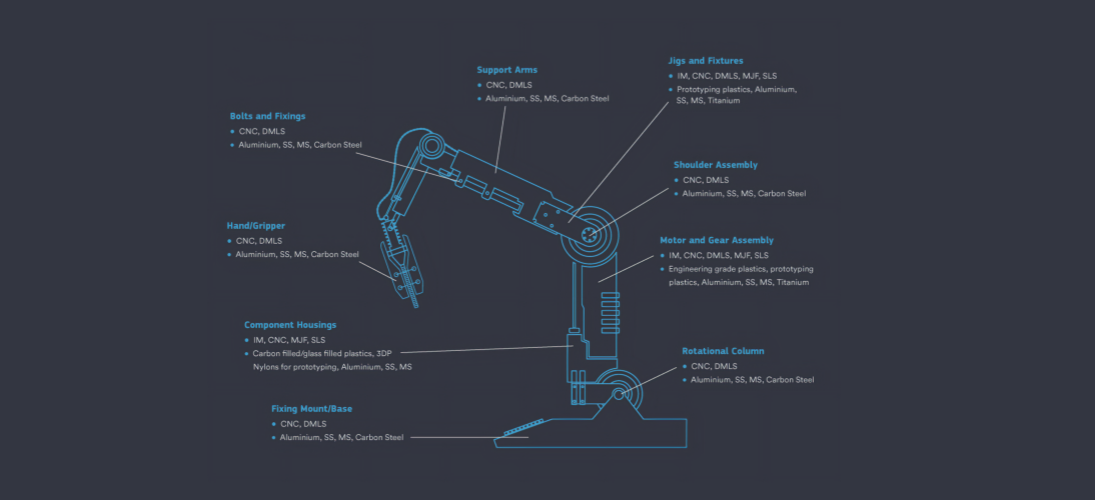

Structure Diagram

Product parameters

Model | GR-100 | GR-200DLR | GR-500DLR | GR-20CP | GR-1500SRC | GR-1500UPS |

Weight | 80 kg | 145 kg | 240 kg | 120 kg | 800 kg | 250 kg |

Payload | 100 kg | 200 kg | 500 kg | 20 kg | 1500 kg | 1500 kg |

Dimensions (LxWxH) | 720 x 520 x 380 mm | 900 x 660 x 280 mm | 1100 x 750 x 300 mm | 900 x 650 x 2400 mm | 1830 x 1550 x 850 mm | 1080 x 1030 x 150 mm |

Speed | 1.2 m/s | 1.2 m/s | 1.2 m/s | 1.2 m/s | 1.0 m/s (1.2 m/s without load) | 1.2 m/s |

Charging Mode | Manual/Smart Dock | Opportunistic Charging | Opportunistic Charging | Opportunistic Charging | Opportunistic Charging | Opportunistic Charging |

Operation Duration | 8 hours | 8 hours | 8 hours | 8 hours | 8 hours | 8 hours |

Battery | 24V 30 Ah Lithium Ion (LFP) | 24V 40 Ah Lithium Ion (NMC) | 48V 60 Ah Lithium Ion (LFP) | 48V 300 Ah Lithium Iron (LFP) | 48V 60 Ah Lithium Iron (LFP) | 24V 50 Ah Sealed Lead Acid |

Navigation Method | Inertial Measurement Unit (IMU) aided by LIDAR, Magnetic Tape and/or Vision | Inertial Measurement Unit (IMU) aided by LIDAR, Magnetic Tape and/or Vision | Rail Guided | Rail Guided | Inertial Measurement Unit (IMU) aided by LIDAR, Magnetic Tape and/or Vision | Inertial Measurement Unit (IMU) aided by LIDAR, Magnetic Tape and/or Vision |

Fleet Management System | Web API for interface with ERP/MES/WMS | Web API for interface with ERP/MES/WMS | Web API for interface with ERP/MES/WMS | Web API for interface with ERP/MES/WMS | Web API for interface with ERP/MES/WMS | Web API for interface with ERP/MES/WMS |

Communication | Wi-Fi 2.4 GHz/5GHz, 802.11 a/b/g/n/ac | Wi-Fi 2.4 GHz/5GHz, 802.11 a/b/g/n/ac | Wi-Fi 2.4 GHz/5GHz, 802.11 a/b/g/n/ac | Wi-Fi 2.4 GHz/5GHz, 802.11 a/b/g/n/ac | Wi-Fi 2.4 GHz/5GHz, 802.11 a/b/g/n/ac | Wi-Fi 2.4 GHz/5GHz, 802.11 a/b/g/n/ac |

Front Safety | Scanning Laser | Scanning Laser | Scanning Laser | Bumper Sensor | Scanning Laser | Scanning Laser |

Rear Safety | None | None | None | None | Front and Rear Bumper | Front and Rear Bumper |

Application

Material Handling: The GR Manipulator efficiently retrieves and transports small, delicate materials or heavy items, improving material flow in manufacturing environments.