Product Description

The miniature brushless DC motor has advanced drive circuit, and adopts high-performance power semiconductor devices and optimized control chips to achieve high integration. This not only reduces the number of wiring and components of the external circuit, but also improves the stability and reliability of the system. At the same time, it has the characteristics of turning on the power, when the 12V/24V DC power supply is connected, the motor can respond quickly, start smoothly and reach the rated speed. During the startup process, the current impulse is small, the impact on the power supply and other circuit components is minimal, and the motor can be started and stopped frequently without affecting the life and performance of the motor.

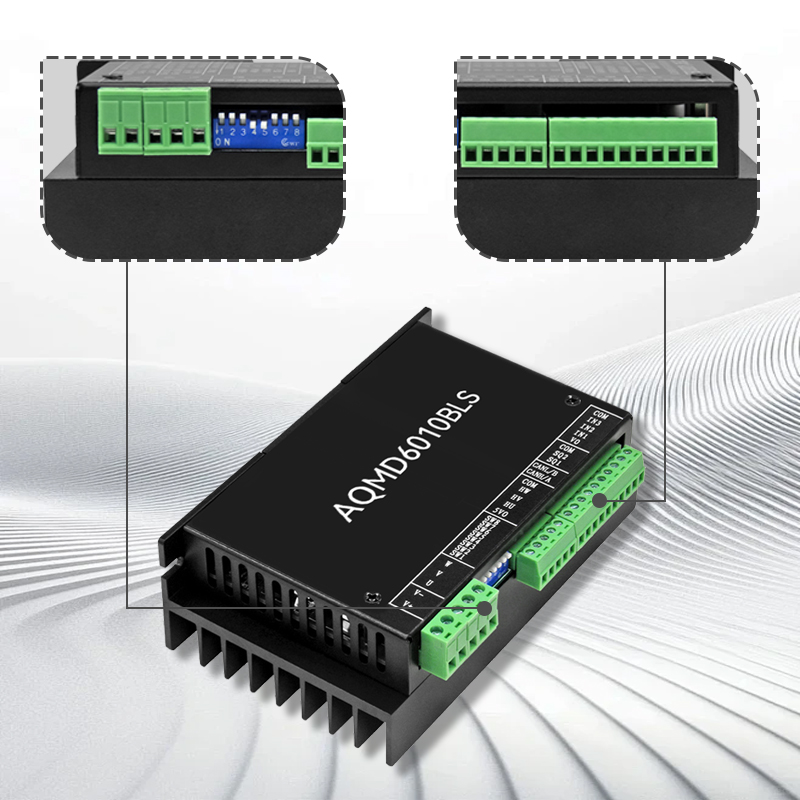

Product Display

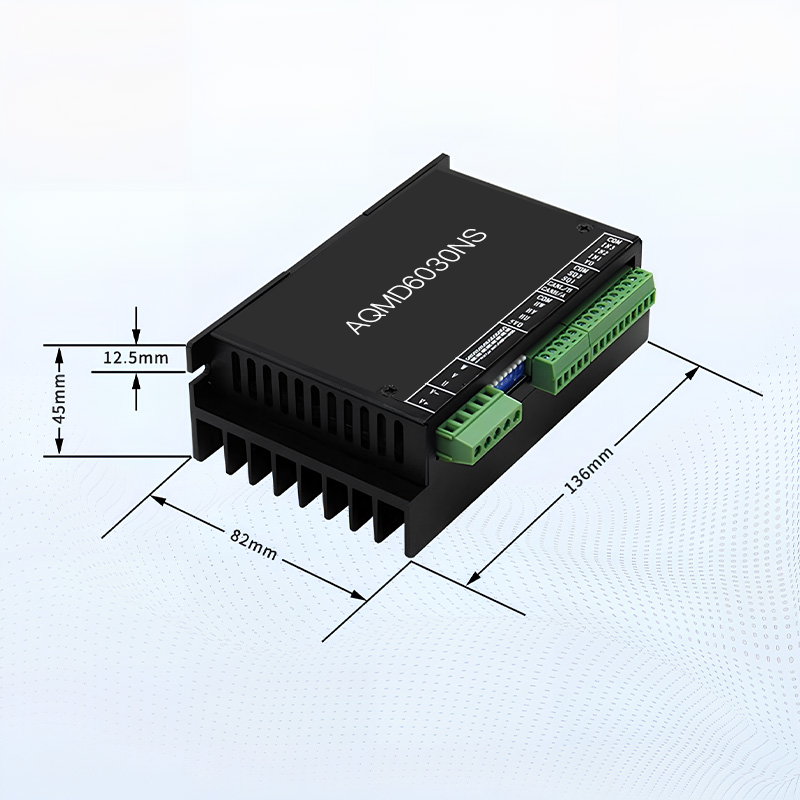

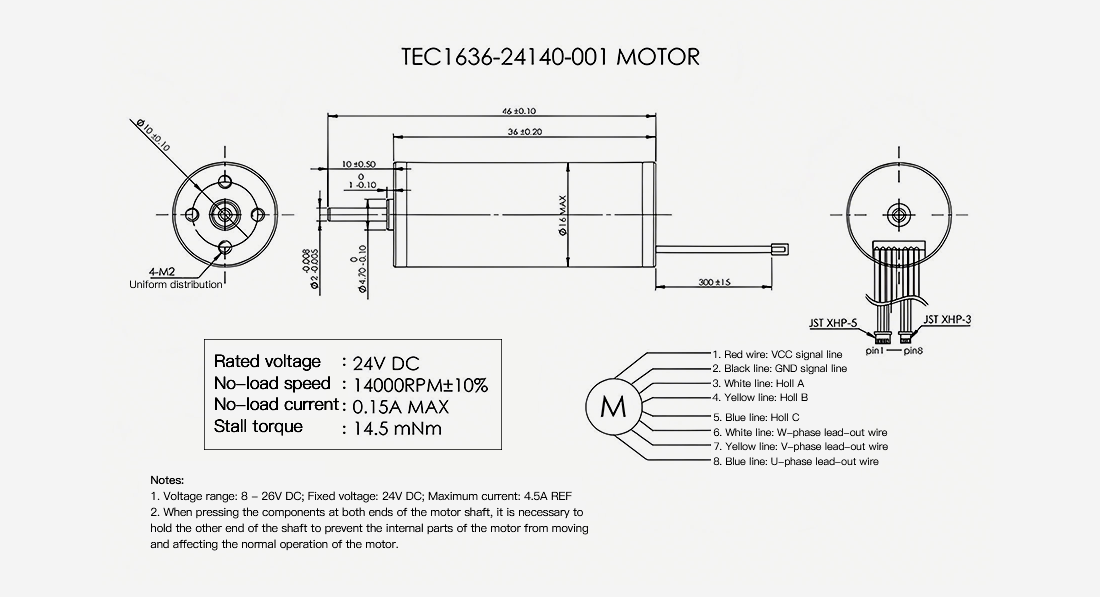

Dimensional drawing

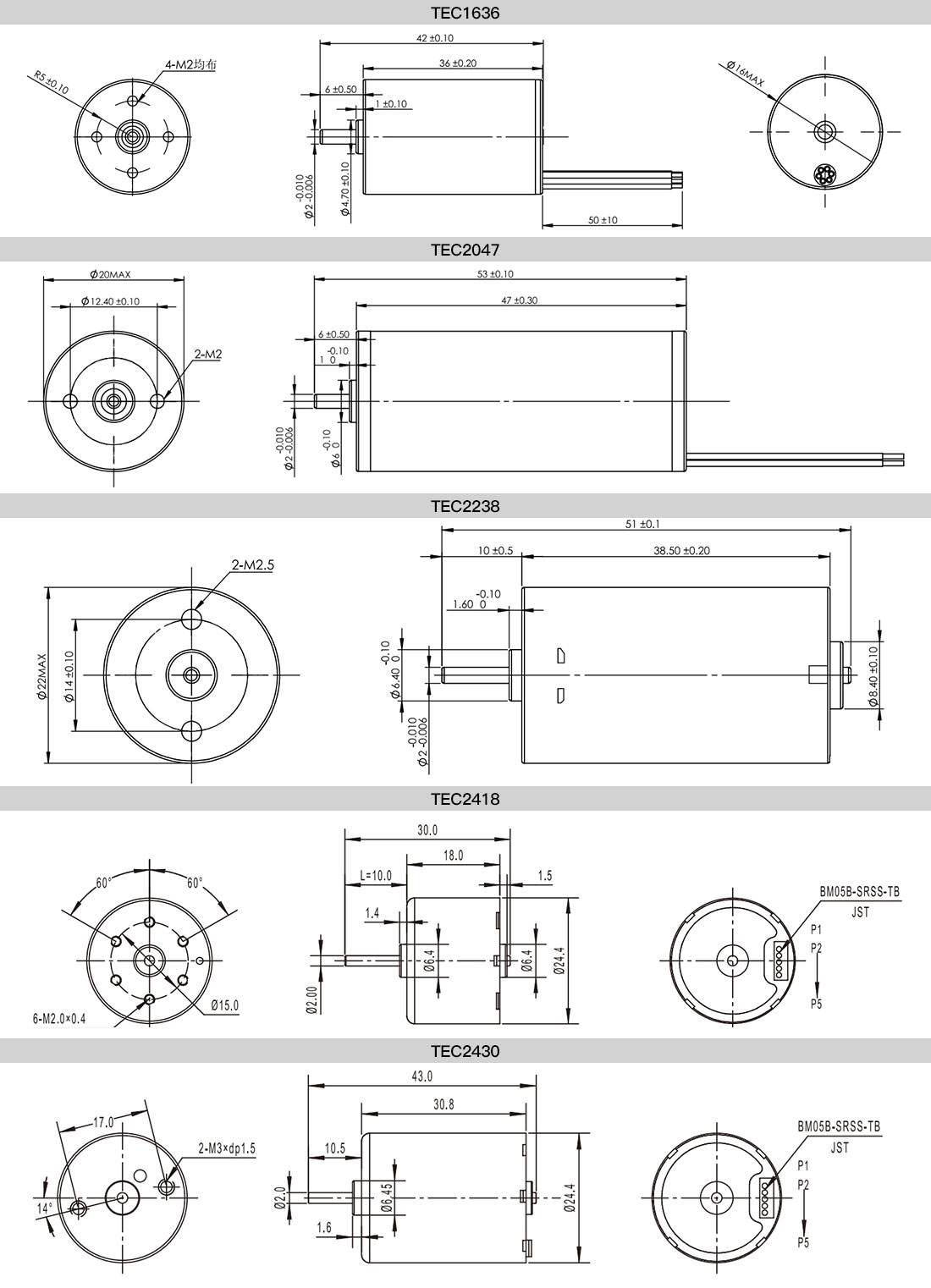

Wiring Instructions

Connection mode A (TEC24 series) | |||||

pin NO. | SIGNAL | I/O | specification | remark | |

P1 | GND | IN | Ground | Black wire , Ground | |

P2 | Motor power supply positive interface VCC | IN | 12v (operating range:8 . 5v~ 15v) | Red wire , motor power supply | |

P3 | FG | VOH | OUT | 1 . 5≤V≤5 . 0 | yellow wire , which can detect the |

VOL | 0 . 6v max | ||||

FG Current | 3mA max | ||||

FG Pulse quantity | 9 pulses round | ||||

P4 | PWM | Input voltage | IN | 0 ~ 5 . ov | white wire |

VIH | Min 1 . 5v | High level , stop | |||

VIL | Max 0 . 6v | Low level , run | |||

PWM Frequency | Advise 20KHz~ 30KHz | / | |||

P5 | CW/CCW | Input voltage | IN | 0 ~ 5 . ov | orange wire , Ccw cw switch |

VIH | Min 1 . 5v | High level =ccw | |||

VIL | Max 0 . 6v | Low level =cw | |||

| |||||

Connection mode B (TEC28 series) | |||||

pin NO. | SIGNAL | I/O | specification | remark | |

P1 | Motor power supply positive interface VCC | IN | 12v (operating range:8 . 5v 15v) |

| |

P2 | GND | IN | Ground | Black wire , Ground | |

P3 | FG | VOH | OUT | 1 . 5≤V≤5 . 0 | yellow wire , which can detect the |

VOL | 0 . 6v max | ||||

FG Current | 3mA max | ||||

FG Pulse quantity | 3 pulses/round | ||||

P4 | CW/CCW | nput voltage | IN | 05 . ov | white wire , Ccw/cw switch |

VIH | Min 1 . 5v | High level =ccw | |||

VIL | Max 0 . 6v | Low level =cw | |||

P5 | PWM | nput voltage | IN | 05 . ov | Blue wire |

VIH | Min 1 . 5v | High level, stop | |||

VIL | Max 0 . 6v | Low level , run | |||

PWM Frequency | Advise 20KHz~ 30KHz | / | |||

Note: | |||||

Connection mode C | |||||

pin NO. | SIGNAL | I/O | specification | remark | |

P1 | Motor power supply positive interface VCC | IN | 12v (operating range:8 . 5v ~ 15v) |

| |

P2 | FG | VOH | OUT | 1 . 2≤V≤5 . 0 | yellow wire , which can detect the |

VOL | 0 . 5v max | ||||

FG Current | 3mA max | ||||

FG Pulse quantity | 6 pulses/round | ||||

P3 | CW/CCW | Input voltage | IN | 0 ~ 5 . ov | white wire , Ccw/cw switch |

VIH | Min 1 . 5v | High level =ccw | |||

VIL | Max 0 . 6v | Low level =cw | |||

P4 | GND | IN | Ground | Black wire , Ground | |

P5 | PWM | Input voltage | IN | 0 ~ 5 . ov | Blue wire |

VIH | Min 1 . 5v | High level Motorstop | |||

VIL | Max 0 . 6v | Low level , run | |||

PWM Frequency | Advise 20KHz ~ 30KHz | / | |||

P6 | BRAKE | Input voltage | IN | 0 ~ 5 . ov | Green wire |

VIH | Min 1 . 5v | High levEl , Motor start | |||

VIL | Max 0 . 6v | Low level , Motor stop | |||

Note: | |||||

Product parameters

Motor model | Ratedvoltage | No-load | Rated | Stall | |||||

Speed | Current | Speed | Torque | Current | power | Torque | Current | ||

VDC | r/min | mA | r/min | g.cm | mA | W | g.cm | A | |

TEC1636-1290 | 12 | 9000 | 73 | 6700 | 20 | 230 | 1.45 | 128.6 | 1 |

TEC1636-24120 | 24 | 12000 | 50 | 9150 | 20 | 155 | 1.9 | 85.7 | 0.54 |

TEC2047-1250 | 12 | 5000 | 39 | 3300 | 30 | 160 | 1 | 83 | 0.35 |

TEC2047-2487 | 24 | 8700 | 32 | 7079 | 30 | 135 | 2.2 | 162.5 | 0.55 |

TEC2238-1250 | 12 | 5000 | 45 | 3100 | 50 | 300 | 1.6 | 137 | 0.75 |

TEC2238-2480 | 24 | 8000 | 40 | 6100 | 50 | 240 | 3 | 225 | 0.93 |

TEC2418-1262 | 12 | 6200 | 60 | 4943 | 33.6 | 230 | 1.7 | 160 | 0.87 |

TEC2418-2487 | 24 | 8700 | 52 | 6817 | 37.4 | 180 | 2.62 | 170 | 0.65 |

TEC2430-1255 | 12 | 5500 | 90 | 4504 | 53.2 | 380 | 2.46 | 280 | 1.6 |

TEC2430-2455 | 24 | 5500 | 50 | 4500 | 66.5 | 220 | 3.07 | 350 | 0.94 |

Note: Power can be customized according to customer requirements. | |||||||||

Motor model | Connection mode | Reversible function | Signal output function | Pulse width speed regulation function | Lock protection | Maximum power | Motor life |

TEC1636-1290 | Connection mode C | Rotate clockwise/counterclockwise | FG signal | PWM control | Locking rotor protection | 2W(Built-in driver) | About 5000H(ball bearing) |

TEC1636-24120 | |||||||

TEC2047-1250 | Connection mode is insensitive | Rotate clockwise/counterclockwise | FG signal | PWM control | Locking rotor protection | 3W(Built-in driver) | About 5000H(ball bearing) |

TEC2047-2487 | |||||||

TEC2238-1250 | Connection Mode A | Rotate clockwise/counterclockwise | FG signal | PWM control | Locking rotor protection | 3W(Built-in driver) | About 3000H(oil bearing) |

TEC2238-2480 | |||||||

TEC2418-1262 | Connection Mode A | Rotate clockwise/counterclockwise | FG signal | PWM control | Locking rotor protection | 3W(Built-in driver) | About 3000H(oil bearing) |

TEC2418-2487 | |||||||

TEC2430-1255 | Connection Mode A | Rotate clockwise/counterclockwise | FG signal | PWM control | Locking rotor protection | 3W(Built-in driver) | About 3000H(oil bearing) |

TEC2430-2455 |

Application

Brushless motor has many advantages such as high efficiency and energy saving, good control performance, stable operation, high power density and low electromagnetic interference. The company's products are widely used in: label printer, label stripping machine, barcode printer, robot, electronic door lock, printer, electronic monitor, display stand, counter, vending machine and auto parts, smart kitchen and bathroom, household appliances, medical equipment, communication equipment, industrial equipment, instruments and meters, model aircraft, robots, personal care, security camera, digital electronics and other lines Can be customized according to different needs of customers.

After-sale guarantee

If the motor fails, our after-sales team will respond in the first time, and quickly arrange professional and technical personnel to communicate with you to understand the details of the fault. We will provide you with remote technical guidance to help you solve the problem according to the specific situation. At the same time, we also provide you with regular return visit service, understand the use of the motor, collect your comments and suggestions, in order to continuously optimize products and services. When the product is upgraded, we will also notify you in time to provide you with the corresponding technical support and solutions, so that your equipment always maintains good performance.