Product Description

This electric gripper adopts stepper motor closed-loop control combined with encoder, and the gripping transmission device is a ground ball screw single-axis robot. Its gripping force, position, speed, and acceleration are all adjustable. The fixture is compact and has the characteristics of high speed, high precision, high rigidity, and high efficiency. It is suitable for industrial production, scientific research experiments, and other scenarios, and is a good choice for improving work efficiency.

Product parameters

Model | XEG-16 | XEG-32 | XEG-64 | ||

Electric gripper | Stroke[both sides](mm) | 16±0.5 | 32±0.5 | 64±0.5 | |

Gripping Force(N) | 25~50 | 60~150 | 180~450 | ||

Speed(mm/s) | Motion | 1~60 | 1~80 | 1~100 | |

Gripping[Note2] | 1~10 | 1~20 | 1~20 | ||

Repeatability(mm) | ±0.01 | ±0.01 | ±0.02 | ||

Drive Device | Single axis robot | ||||

Grease Supply of Drive Device[Note3] | 500,000 cycles or 6 months | ||||

Impact/Vibration Resistance(m/s2) | 150/30 | ||||

Operating Temperature Range(℃) | 5~45 | ||||

Operating Humidity Range(%) | RH35~85(No condensing) | ||||

IP Class | IP20 | ||||

Weight(kg) | 0.4 | 0.7 | 1.9 | ||

Controller | Motor Type | Stepper motor | |||

Motor Size(mm) | □20 | □28 | □42 | ||

Power Supply(V) | DC 24±10% | ||||

Total Current(A) | 0.5A | ||||

Weight(Kg) | 0.1 | ||||

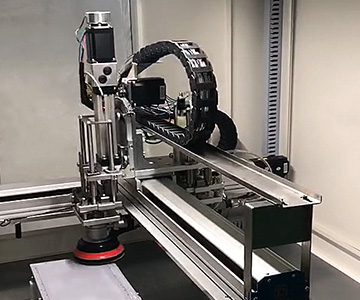

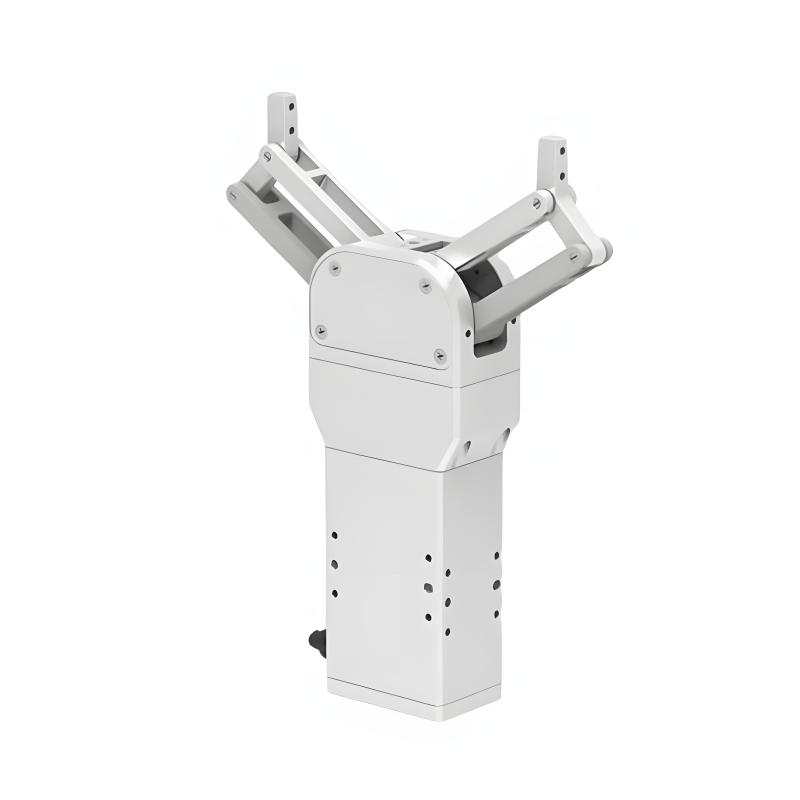

Product Display

Electric grippers have excellent performance for items such as glass products and precision electronic components that require extremely high gripping force. They can accurately adjust the gripping force to avoid breaking, deformation or surface scratches of items due to improper force, and achieve safe and stable gripping and handling.

The electric gripper has good versatility and can be perfectly adapted to robotic arms of different brands and models. When used with a robotic arm, it can break through space limitations and flexibly complete grasping tasks in various complex locations, greatly expanding the scope of work.

In the material handling process of industrial production, time is efficiency. Before approaching the target, the electric gripper can run at high speed and quickly reach the designated position. When approaching the target, it can intelligently switch to low-speed mode to complete the clamping action gently and accurately, ensuring the safety and accuracy of the grasping process.

The electric gripper has an advanced built-in measurement and recognition system that can quickly and accurately measure the contours and dimensions of the three types of workpieces. Based on these data, the gripper can automatically identify different workpieces and match the corresponding grasping strategy, effectively reducing manual intervention and greatly improving work efficiency.

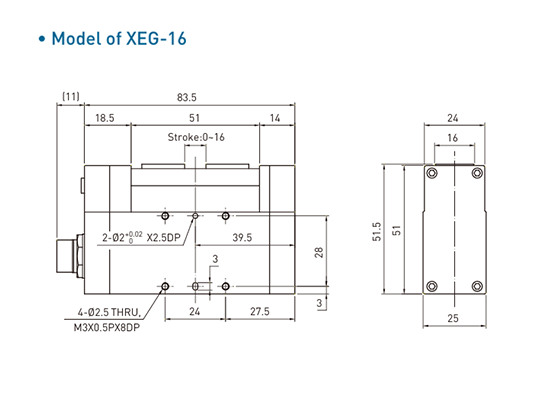

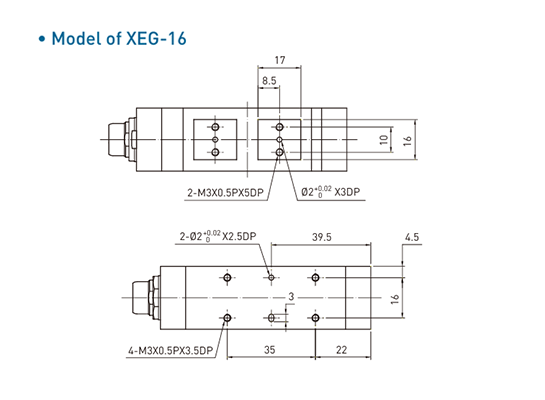

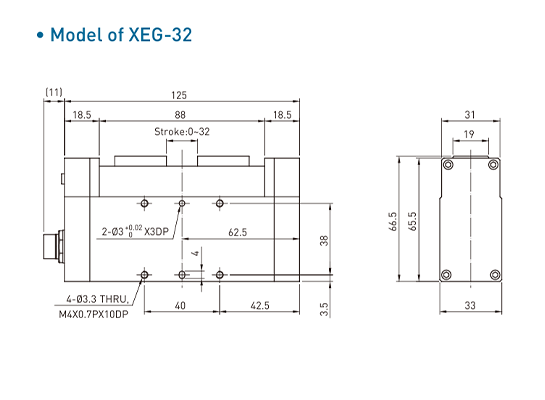

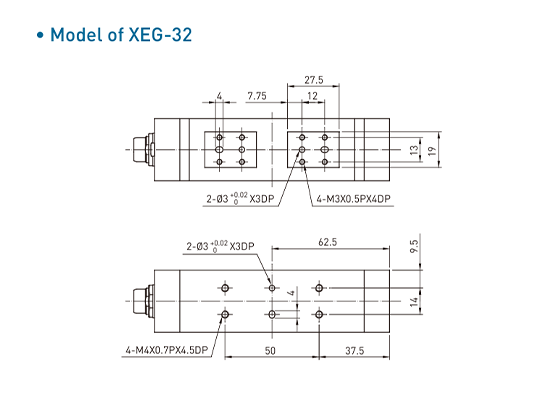

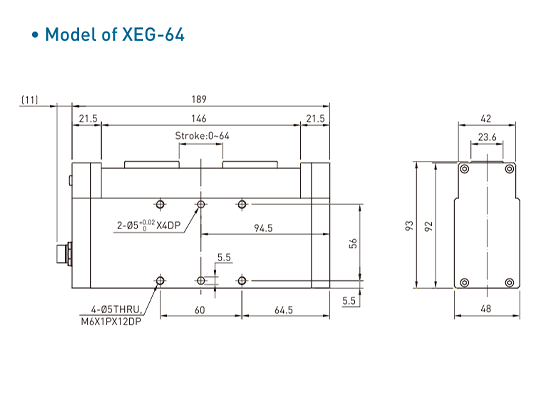

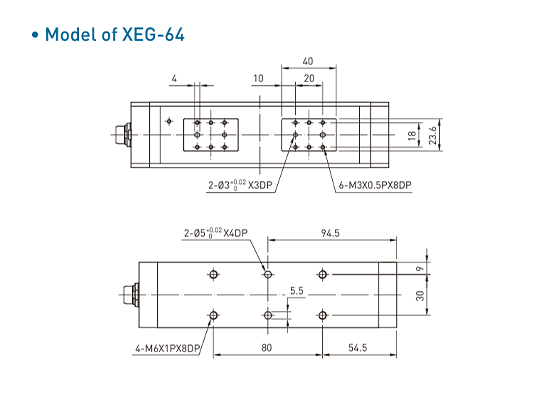

Size & Interface

Application Cases

In response to diverse work needs, the electric gripper provides a variety of action mode options. Users can freely set multiple action modes according to actual work scenarios, such as material handling, parts assembly, etc., to achieve efficient and precise operations.