Product Description

We specialize in factory OEM customization services and are proficient in metal parts processing. Relying on advanced technology, we are good at customized metal casting, especially high-pressure die casting. We can produce all kinds of aluminum alloy parts. With our in-depth mastery of die-casting technology, we strictly control every process to ensure that the parts are accurate in size and stable in performance to meet your diverse needs.

Product parameters

Size | Customized Size\Client's Drawings |

Surface treatment | Painting,Powder Coating,Polishing, Electroplating, Sand Blasting |

Process | Die Casting. Deburring .CNC Machining .Inspection.Packaging |

Certification | ISO 9001:2015/IATF 16949:2016/ISO 14001:2015 |

Custom Process

1.Demand communication

2.Product Design

3.Mold making

4.Material preparation

5.Process determination

6.Foundry production

7.Post-processing

8.Inspection and delivery

Process Type

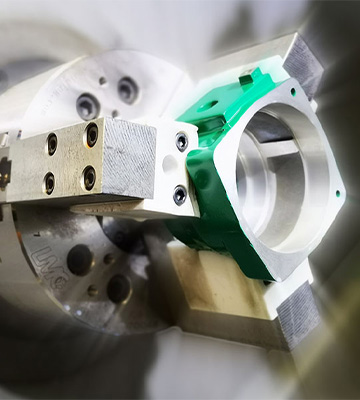

Milling process

Milling is a type of mechanical processing, in which the rotation of the milling cutter is the main motion, and the movement of the workpiece or the milling cutter is the feed motion. It can process various shapes such as planes, grooves, and forming surfaces. It has a variety of tools, high processing accuracy and efficiency, and is widely used in the field of mechanical manufacturing.

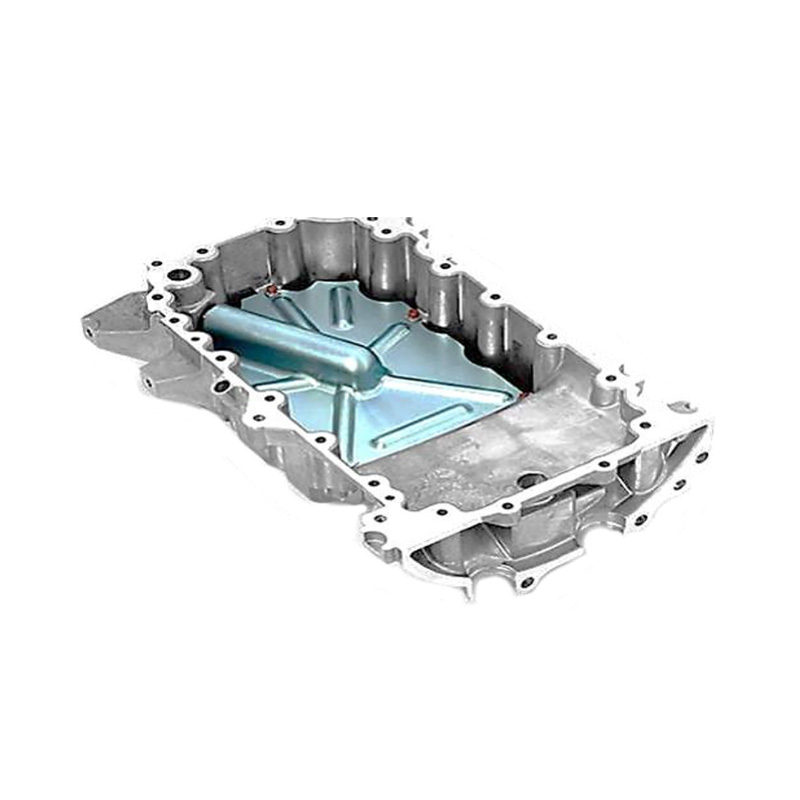

High-pressure die casting

High-pressure die casting is a metal casting process that uses high pressure to quickly inject molten metal into the mold cavity and cool it to form. It has the advantages of high production efficiency, good casting precision, and good surface quality. It is widely used in the automotive, aviation and other industries.

Turning process

Turning is a machining process in which the workpiece rotates and the turning tool moves and cuts on a lathe. It can perform a variety of turning operations such as external circles, internal holes, threads, and end faces. It has high machining accuracy and good surface quality, and can process a variety of materials.

Material

Steel

Brass

Aluminum

Copper

Quality Control

We place top priority on the quality of our products to meet the demanding requirements and expectations of our customers by implementing a formal Quality System with following principles:

1. We are committed to provide excellent quality products to fulfill the existing and changing needs of our customer

2. We are committed to practice and maintain the MS ISO 9001 : 2015 and IATF 16949 : 2016 Quality Management System

3. We shall strive to continuosly improve our products and processes towards quality excellence

4. We shall strive to instill a high spirit of quality awareness into our working culture

Processing capability

Die Casting

· Cold-Chamber Machines from 350-1,000 Tons (12 Machines with individual furnace for a variety of alloys).

· We Use Standard alloys such as ADC12, A380, ADC10, LM6, A413 & A360.

· We also use special composition alloys upon request from customer.

· Capability to cast small parts from 10g up to larger part weighting 5kg.

· Our product quality meet pressure tight, structural and high cosmetic requirement.

Additional processes

Powder coating

Enhancing the durability and aesthetic appeal of our diecast components, Sena Diecasting offers superior powder coating Malaysia services. Our powder coating solutions provide a high-quality finish that resists corrosion, scratches, and fading, ensuring that your components maintain their appearance and functionality over time.