Product Description

We provide professional OEM customized high-pressure die casting services. Our technical team is experienced and has a deep understanding of various design requirements. From early communication to mold making, and then to the final die casting molding, we use exquisite craftsmanship and strict quality inspection to ensure that every product meets your high standards.

Product parameters

Color | Customized Color |

Application | Industry |

Material | Steel, brass, copper, aluminum, etc. |

Quality Control | 100% Inspection |

Custom Process

Demand communication

Product Design

Mold making

Material preparation

Process determination

Foundry production

Post-processing

Inspection and delivery

Material

Brass

Steel

Copper

Aluminum

Quality Control

1.Expertise and Experience: With years of experience in the industry, Sena Diecasting has honed its skills and expertise, making us a trusted name in diecasting.

2.Advanced Technology: We utilize the latest technology and equipment to ensure that our diecasting processes meet the highest standards of quality and efficiency.

3.Comprehensive Services: From diecasting to finishing and plating, Sena Diecasting offers a full range of services to meet all your needs.

Processing capability

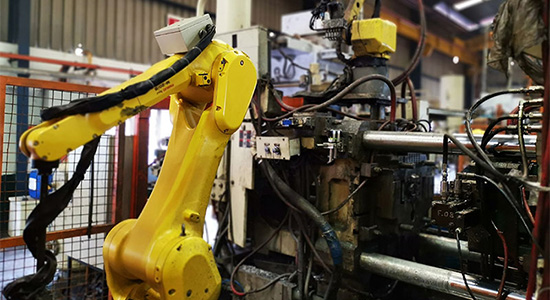

Full Automation Robotic System

Robotic for Die Casting

· Full Automation

· Consistency of casting quality.

· Reduction of labor cost.

· Increase productivity.

Additional processes

Polishing process

Mechanical polishing: Use a polishing wheel (made of cotton, wool, leather, etc.) and polishing paste or polishing liquid (containing abrasives such as aluminum oxide, silicon carbide, etc. and lubricants) to rub the surface of the workpiece to remove tiny surface bumps and make the surface smooth.