Product Description

We are a leading custom parts manufacturer specializing in high-quality OEM custom processing. With advanced CNC turning and milling technology, we are able to process CNC spare parts with ease. From design conception to finished product delivery, we strictly control the entire process and use superb craftsmanship to create high-precision, custom parts that meet your needs.

Product parameters

Material | Aluminum Brass Plastic Steel |

Process | CNC Machining |

Surface treatment | Painting\Powder Coating\Plating\Polishing |

Application | Industrial Equipment |

Service | Customized OEM CNC Machining |

Custom Process

1. Demand communication

2. Solution design

3. Quotation

4. Contract signing

5. Prepayment

6. Production delivery

7. Inspection and acceptance

8. Final payment settlement

Process Type

CNC machine workshop turning

In the CNC machine workshop, the turning process operates efficiently. The workpiece is firmly fixed on the spindle chuck and rotates rapidly. The turning tool cuts accurately according to the CNC program instructions. Amid the flying metal chips, the shape of the rotating body is gradually formed, and high-precision parts are born, injecting strong power into the manufacturing industry.

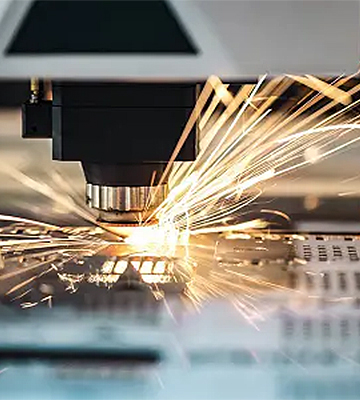

Laser Process

Using a high-energy-density laser beam to irradiate the surface of a material, the material is instantly melted and vaporized, and operations such as cutting, welding, and surface treatment are achieved. A variety of materials can be processed, including metals and non-metals. Laser cutting has high precision, high speed, and a small heat-affected zone; laser welding has high strength and small deformation; laser surface treatment can improve the surface properties of materials.

Welding process

When the manifold is composed of multiple components, welding is a critical process. For example, some large and complex industrial manifolds may first be processed into several small components, and then connected into a complete manifold by welding. To ensure that the sealing and strength of the welds meet the use standards, advanced welding technologies such as argon arc welding and laser welding are often used to ensure welding quality.

Material

Copper

Steel

Aluminum

Stainless steel

Quality Control

As a professional precision machining manufacturer, we regard quality as our soul. We select high-quality raw materials, use advanced equipment and exquisite craftsmanship, and implement strict monitoring throughout the entire processing process. The finished products undergo multiple precision testing processes to ensure that no minor defects are missed, just to provide you with mechanical processing products with excellent precision and high quality.

Processing capability

Precision CNC machining is an advanced automated machining method that uses a computer digital control system to precisely control the movement and operation of machine tools. Through pre-written program codes, the tool path, cutting speed, feed rate and other parameters are precisely controlled to perform milling, drilling, boring, tapping and other machining operations on various materials such as metals and plastics. It can efficiently and accurately manufacture parts with complex shapes and extremely small tolerances. It is widely used in many high-end manufacturing fields such as aerospace, automobiles, electronics, and medical equipment, and has effectively promoted the precision development of modern industry.

Additional processes

Spray paint

Spray painting is a process that uses a spray gun to atomize the paint and then evenly spray it on the surface of an object. In this process, the paint will build a continuous thin film on the surface of the object. After this thin film dries and solidifies, it will firmly adhere to the surface of the object, playing a dual role of protection and decoration. The atomization process is extremely critical, which can make the paint particles extremely small and evenly distributed, laying a solid foundation for ensuring the quality of the coating, and finally presenting a smooth surface and uniform color.