Product Description

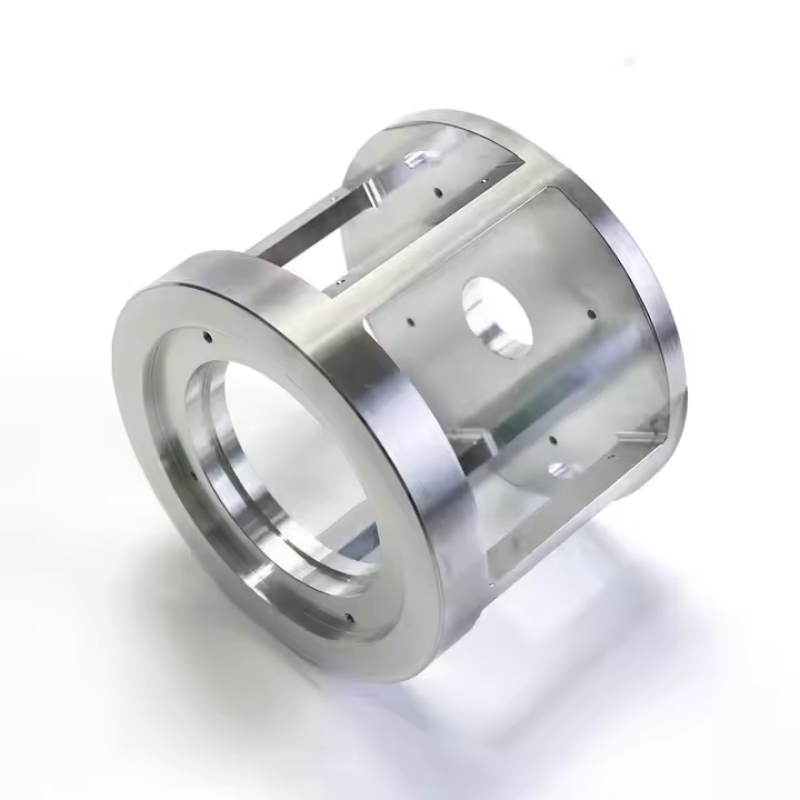

With mature CNC technology, we focus on the production of non-standard metal processing accessories, strictly control dimensional accuracy, and adapt to the operation needs of complex equipment.

Product parameters

Material | Steel or Carbide |

Accuracy | Subject to the drawing details. |

Delivery time | 14 days |

Urgent delivery | 7 days |

Color | Silver |

Size | Customzied |

Tolerance | 0.02 to 0.10 mm |

Raw material | Aluminum, Titanium, Copper, Stainless Steel, Steel Alloy, Inconel, cast iron |

Process | CNC Machining Milling Turning |

Service | One Stop Service. Machining-assembly |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test before packing

8. Shipping & confirmation

Process Type

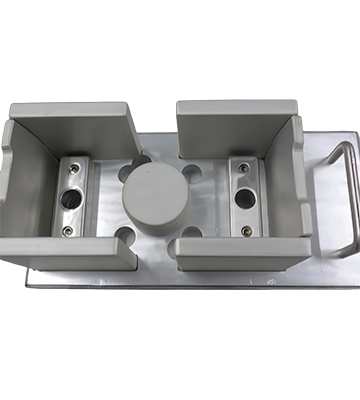

Processing module

Structural processing

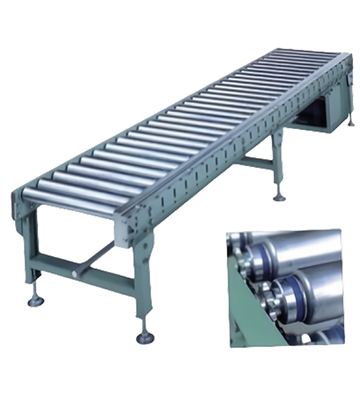

Machine manufacturing

Material

Cast iron

Brass

Aluminum

Alloy steel

Quality Control

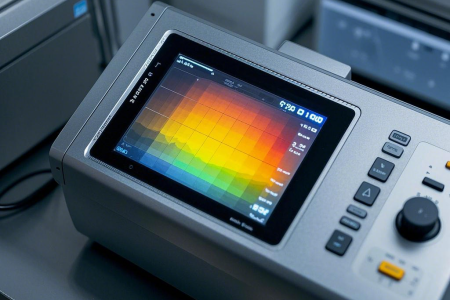

Spectrometers use the absorption or emission characteristics of substances to analyze the chemical composition of substances. By exciting the sample to produce a spectrum and then analyzing the spectrum, the types and contents of various elements in the sample can be accurately determined. In the customization of non-standard OEM mechanical parts, it is often used to detect the chemical composition of raw materials and accessories.

The three-dimensional coordinate measuring machine can perform precise measurements in three mutually perpendicular directions. By contacting the probe with the surface of the object being measured, the three-dimensional coordinate data of the object is obtained, and then the size, shape, position and other parameters of the object are calculated. It can perform high-precision measurements of geometric parameters such as length, width, height, aperture, cylindricity, flatness, verticality, parallelism, etc. of mechanical parts. It is widely used in the production process of various non-standard OEM mechanical parts and the finished product inspection stage.

Processing capability

The three-dimensional coordinate measuring machine can perform precise measurements in three mutually perpendicular directions. By contacting the probe with the surface of the object being measured, the three-dimensional coordinate data of the object is obtained, and then the size, shape, position and other parameters of the object are calculated. It can perform high-precision measurements of geometric parameters such as length, width, height, aperture, cylindricity, flatness, verticality, parallelism, etc. of mechanical parts. It is widely used in the production process of various non-standard OEM mechanical parts and the finished product inspection stage.

We master various casting processes such as sand casting and precision casting, and accurately inject liquid metal into the mold cavity. After cooling and solidification, we can obtain metal parts with accurate shapes and sizes. No matter how complex the mechanical parts are, such as engine cylinders, pump bodies, etc., they can be perfectly manufactured to meet various production needs

Additional processes

By electrolytically depositing a layer of metal or alloy on the surface of metal parts, such as nickel plating, chrome plating, zinc plating, etc., the corrosion resistance, wear resistance and decorativeness of the parts can be improved. For example, some non-standard metal parts in automobile engines, after chrome plating, not only have a brighter appearance, but also effectively prevent rust.