Product Description

We focus on the production and processing of non-standard machinery parts and components, relying on professional teams and advanced equipment to accurately control the processing process. From drawing design to finished product delivery, we strictly follow customer customization requirements to ensure that each part meets the mechanical operation standards.

Product parameters

Material | Steel or Carbide |

Accuracy | Subject to the drawing details. |

Delivery time | 14 days |

Urgent delivery | 7 days |

Color | Silver |

Size | Customzied |

Tolerance | 0.02 to 0.10 mm |

Raw material | Aluminum, Titanium, Copper, Stainless Steel, Steel Alloy, Inconel, cast iron |

Process | CNC Machining Milling Turning |

Service | One Stop Service. Machining-assembly |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test before packing

8. Shipping & confirmation

Process Type

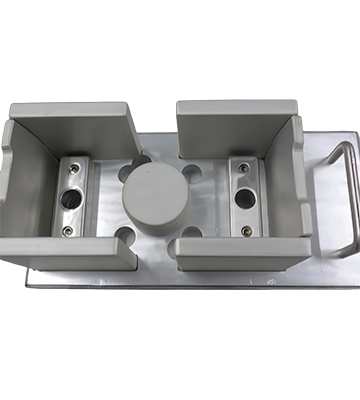

Processing module

Structural processing

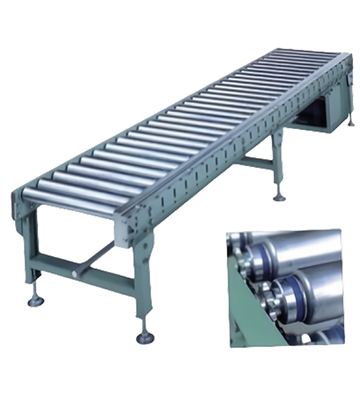

Machine manufacturing

Material

Alloy steel

Cast iron

Aluminum

Brass

Quality Control

2D image measuring instrument

Use optical lens to collect workpiece images, project them onto CCD camera, and then transfer them to computer through image acquisition card. Use professional measurement software to identify and analyze the edge of workpiece contour in the image, and obtain the length, width, angle, roundness and other two-dimensional size parameters of the workpiece based on the conversion relationship between pixels and actual size. For some non-standard parts with obvious plane features, 2D image measuring instrument can quickly and efficiently complete the measurement

Roughness tester

It is divided into contact type and non-contact type. The contact roughness tester slides on the surface of the workpiece through a sensor with a diamond stylus. The stylus moves up and down with the microscopic undulations of the surface, converting the displacement signal into an electrical signal. After amplification and filtering, the surface roughness parameters such as Ra (arithmetic mean deviation of the profile) and Rz (height of ten points of microscopic roughness) are calculated. The non-contact type mostly adopts the principles of optical interference and laser scattering to obtain surface roughness information by analyzing the characteristics of reflected light.

Processing capability

Five-axis linkage processing equipment

On the basis of the traditional three axes (X, Y, Z), two rotation axes (such as A and C axes) are added to enable the tool or workpiece to achieve five degrees of freedom in space. This equipment allows the tool to approach the workpiece at the best angle to achieve efficient and high-precision processing of complex surfaces. The structure of five-axis linkage processing equipment is diverse, including cradle type, vertical double turntable, horizontal double turntable, etc. Each structure is suitable for different types of parts processing.

Use high-energy-density laser beams to irradiate workpieces, causing the materials to melt, gasify or undergo photochemical reactions instantly, thereby achieving processing operations such as cutting, welding, drilling, and surface treatment of workpieces. It can be divided into CO2 laser cutting machines and fiber laser cutting machines. CO2 laser cutting machines have a wide power range and are effective in cutting non-metallic materials such as acrylic, wood, and cloth; fiber laser cutting machines have outstanding advantages in cutting metal materials, with high energy conversion efficiency and high beam quality. Laser welding equipment focuses the laser beam to partially melt the workpiece to form a weld to achieve material connection.

Additional processes

Surface strengthening treatment: For non-standard mechanical parts that are subjected to high pressure and high friction, shot peening can be used. The surface of the parts is sprayed with high-speed projectiles to cause plastic deformation of the surface layer and form residual compressive stress, thereby improving the fatigue strength and wear resistance of the parts. For example, the service life of non-standard transmission gears of construction machinery is significantly extended after shot peening.