Product Description

The company is a leading provider of high-precision CNC turning and milling services, offering custom machining solutions tailored to meet the specific needs of various industries. Utilizing advanced CNC technology, they ensure tight tolerances and superior surface finishes for each part. Their expertise extends to both structural finished and semi-finished product assembly, ensuring that components are delivered fully functional and ready for integration into larger systems.

With a strong focus on quality control, the company adheres to industry standards, providing parts that meet or exceed the expectations of their clients. Their capabilities span across multiple industries, including optics, where precision is crucial for lenses and other optical components, and medical, where reliability and safety are paramount. In the communications sector, they produce high-quality components for antennas, connectors, and other critical applications.

Their automotive parts are designed to withstand the most demanding conditions, while power tools benefit from durable and precise components that enhance performance. Petrochemical components are manufactured with attention to safety and corrosion resistance, essential for the harsh environments they face. The company's commitment to innovation, efficiency, and customer satisfaction has made them a trusted partner in these diverse fields.

| Geometric tolerances | Location | Parallelism | Concentricity | Perpendicularity | Full beat | Symmetry | Flatness | Cylindricity | Roundness |

| symbol |

|

|

|

|

|

|

|

|

|

| Machining accuracy | 0.03 | 0.005 | 0.005 | 0.01 | 0.01 | 0.01 | 0.002 | 0.01 | 0.005 |

| Measurement accuracy | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

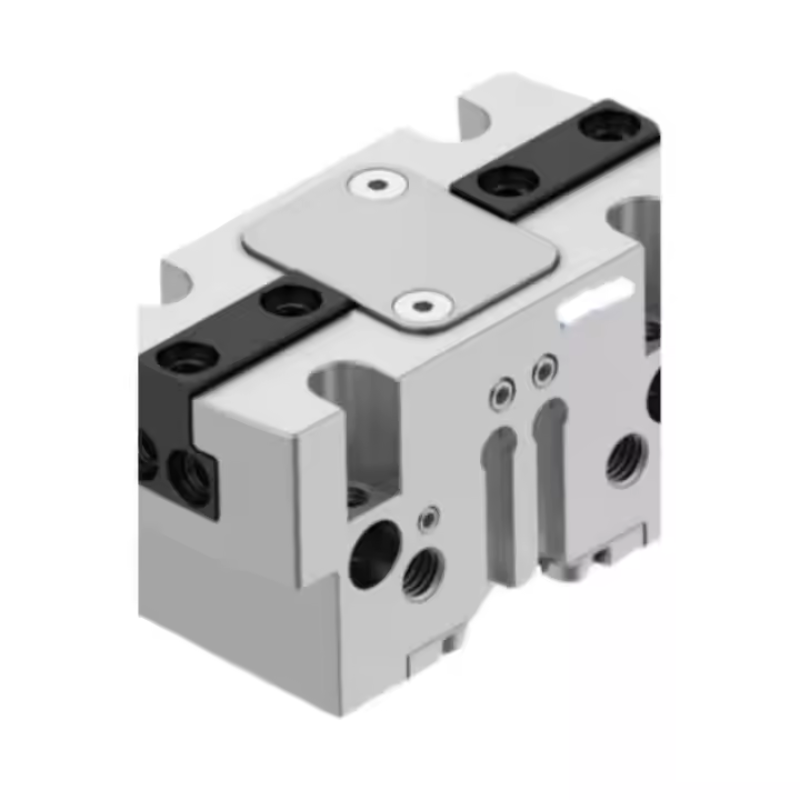

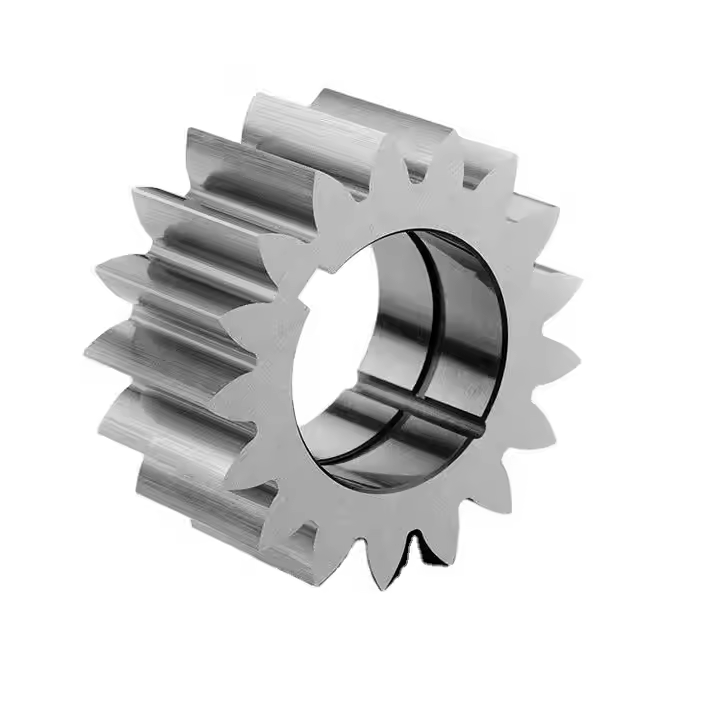

Product Display

|

|

|

|

|

|

|

|

|

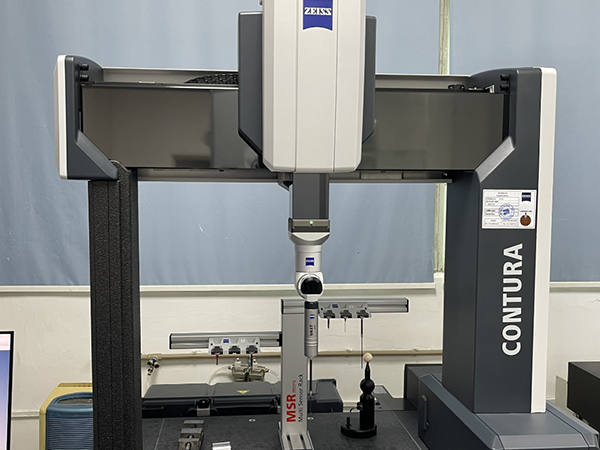

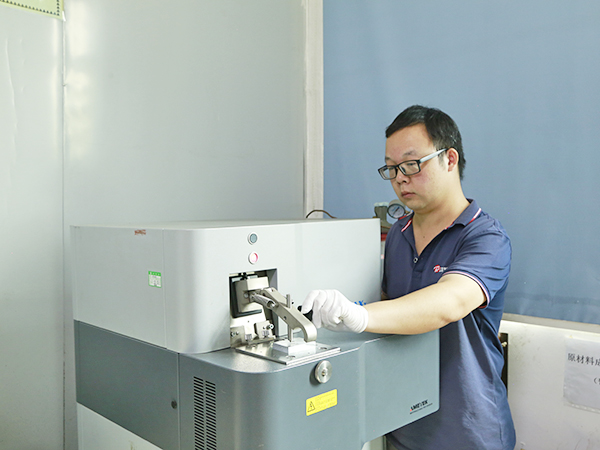

Our Equipment

The company has imported CNC machine tools and testing equipment from Germany, Japan, South Korea, Switzerland, etc., including imported 5-axis CNC machining center, CNC turning and milling compound center, three-dimensional, two-dimensional imported from Switzerland, roughness tester, etc., our equipment is as follows:

CNC lathes

Imported turn-milling compound

Imported core machine

Double-spindle turning and milling center

High-speed CNC milling machine

3-axis/4-axis/5-axis machining center

Precision EDM. Wire cutting

Inside. Cylindrical grinding, surface grinding

Drilling and tapping/polishing/sandblasting/ultrasonic cleaning line

Multi-functional assembly line

|

|

|

|

|

|

|

|

|

Processing Cases

| Name: Pneumatic tool parts Material: Chromium-molybdenum steel + blackening + powder spraying Difficulty Requirements: The deviation of the X.Y.Z axis ± 0.1° Processing technology: Sawing material + quenching and tempering + CNC turning + five-axis turning and milling center + CNC four-axis + deburring + FQC + steel blackening + IQC + shielding + powder spraying + IQC + packaging + OQC |

| Name: Optical parts Material: Aluminum alloy 7075-T6+ black hard anode Difficulty Requirements: The parallelism of the inner cavity is required to be 0.02mm, and the position of all surfaces and holes is required to be 0.02, which needs to be completed by 5 axes at one time Processing technology: CNC 3-axis milling + CNC 5-axis milling + CNC 3-axis milling + deburring + FQC + chrome yellow + IOC + shielding + hard anode + IQC + assembling steel wire screw sleeve + full inspection + packaging + OQC |

| Name: Mechanical accessories Material: Aluminum 7075-T6 + anode natural color 10-15um Difficulty Requirements: Shape and position difference requirements: 0.01mm, need to be CNC turning and milling compound machining Processing technology: CNC turning-milling compound machining + deburring + FQC + surface treatment + IQC + packaging + OQC |

Product parameters

| Specifications | Details |

| Material | Aluminum alloy (6061, 6063, 7075, etc.) |

| Manufacturing Process | CNC Machining, Turning, Milling, Drilling, Tapping |

| Surface Treatment | Anodizing, Sandblasting, Polishing, Coating |

| Tolerance | ±0.01 mm |

| Drawing Format | 2D (PDF, DWG), 3D (STEP, IGS) |

| Production Capacity | Small to large batch production |

| Lead Time | 7-15 days, depending on order quantity |

| Quality Control | 100% inspection before shipment |

| Certification | ISO 9001:2015 |

Custom Process

Consult customer service

Confirm drawings

Online quotation

Confirm order

Five-star praise

Confirm receipt

Packaging and delivery

Processing and produetion

Product protection

Purchase Notice

1、Our company specializes in non-standard customization, processing according to drawings and samples, no stock, please be advised!

2、The prices of all products in this store are not the actual prices of the products. Please consult the customer for quotation verification before placing an order. Orders placed without contact will be deemed invalid orders and will not be shipped. Please be aware of this and thank you for your cooperation.

3、If the customer does not respond to you in time, you can leave a message with your email and phone number and we will contact you later, or you can call us.

4、If it is not customized according to the customer's drawings, we will replace it for free and bear the domestic round-trip freight.

5、Quickly make samples in 3 days, and the minimum batch trial production can be 5 days, with fast delivery.

6、Customize strictly according to the dimensions on the drawings. If there are tolerance problems, we will replace it free of charge.