品牌官方供应商

8 年

品牌官方供应商

8 年

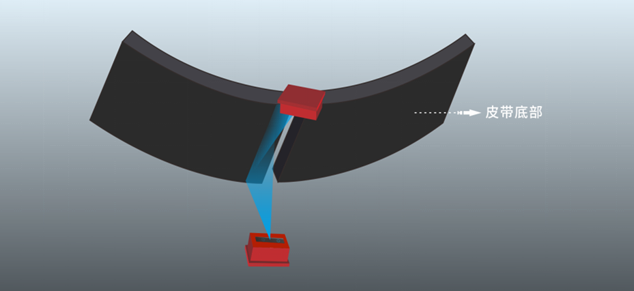

Belt Crack Detection System

Can detect abnormal tearing of belts such as transverse cracks, vertical cracks, longitudinal tearing seams, and longitudinal overlapping of belt conveyors

- Dimension:368*240*190mm

- Accuracy:<3mm

- Support speed of belt:6m/s

- Detection accuracy:>98%

- Detection width:1.2m

- External interface:Gigabit network port / Fiber optic network port

- Supported system:Windows (7、10)

- Required industrial display performance:i7 Sixth generation or later CPU processor,dominant frequency: 3.6GHZ,DDR4 cache, 8GB memory

- Support communication mode:Modbus Tcp communication protocol

- Type:Explosion-proof camera equipment

- Type of laser emitted:450mm wavelength blue laser

- Whether multiple machines can work together:YES

- Voltage:24V/24w

- Working tempoerature:-30℃-70℃

USD: 15000-30000

ablity:Monthly Output200

- Penerangan Produk

- Product Params

Penerangan Produk

The belt tear detection system adopts an artificial intelligence and three -dimensional visual technology system. The coal belt machine of high -speed motion is performed online through a stereo camera. The belt can be split, vertical cracks, and torn seams. The abnormal tear of the belt overlapping and other belts is detected and the belt conveyor is automated in time. It can be installed under the belt through the camera to complete the on -site implementation. The C/S price is used to build a visual data model display platform. A variety of systematic management such as visualization of visualization, detection results, transportation safety detection, and automation control of belt conveyor, greatly improving the automation and intelligent tear detection level of mining belt conveyor.

System Features

Smart terminal, modular design, adapt to the real -time detection of 6M/s high -speed sports scene

The camera instrument is embedded in high -performance image processing module, no additional industrial control host is required

Participate in the bid in the factory camera, quickly implement deployment, convenient and fast

Provide rich system docking interfaces, and can directly connect PLC, inverter, server to quickly complete the refined belt control

Inverter PLC Server

High -precision, high performance, refined data management

In high -speed dynamic detection, real -time and accuracy are in the leading position of the industry

Templage detection accuracy of millimeter -level detection can be tested on small cracks

Meet the requirements of various size conveying belt vision

System software has the characteristics of generalization, which can meet the detection requirements of different sizes of different sizes

You can integrate multiple hardware systems to expand a larger scanning field to meet the detection needs of different locations

Strong adaptability, strong robustness, supporting a variety of complex scenes