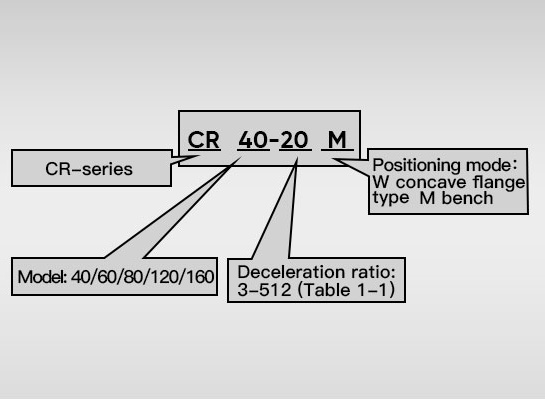

Product Description

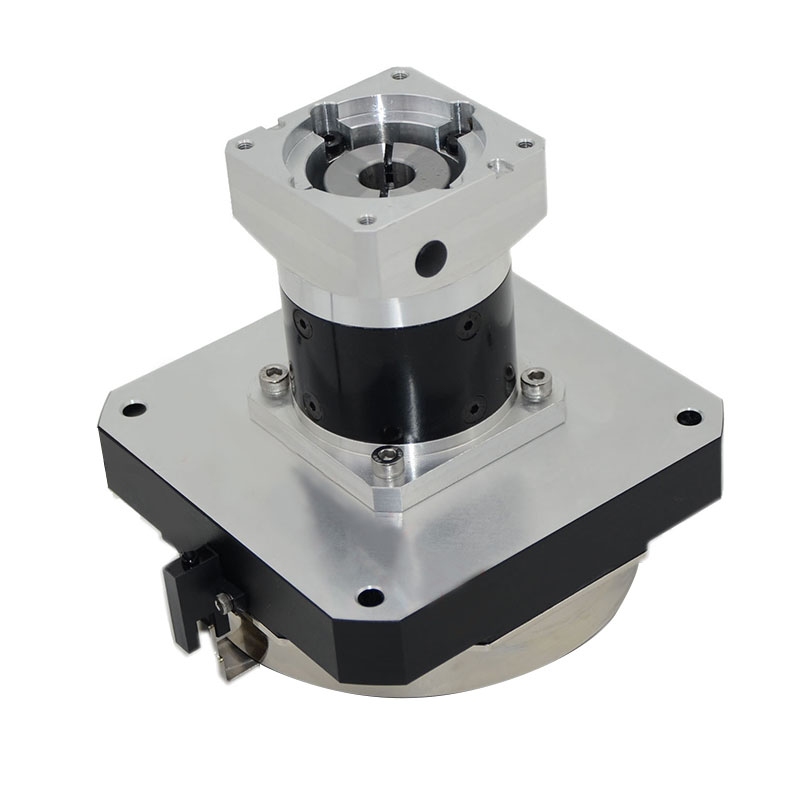

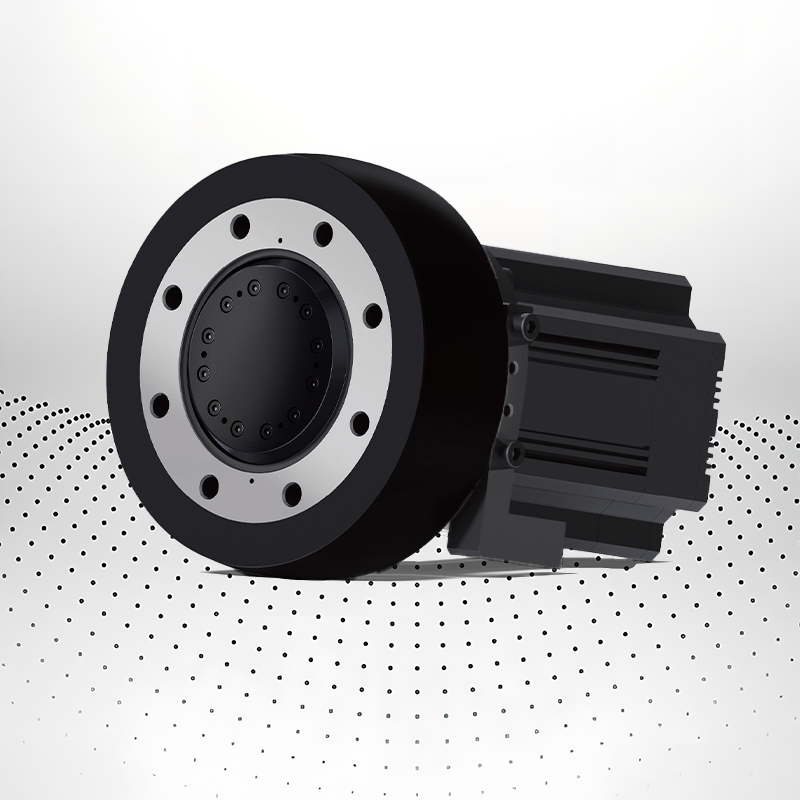

The CR series hollow rotary platform is a high-performance transmission core designed for harsh industrial environments. It adopts an ultra-rigid hollow integrated design, supports efficient penetration of cables, hydraulic pipelines and gas lines, and achieves 360° continuous rotation without dead angles. Combining direct-drive servo motors and zero backlash harmonic reduction technology, it accurately controls the positioning accuracy of the horizontal/vertical axis, adapts to multi-axis linkage and high-speed response scenarios, and is widely used in cutting-edge fields such as heavy-duty robots, aerospace equipment, and high-precision testing instruments.

Functional Features

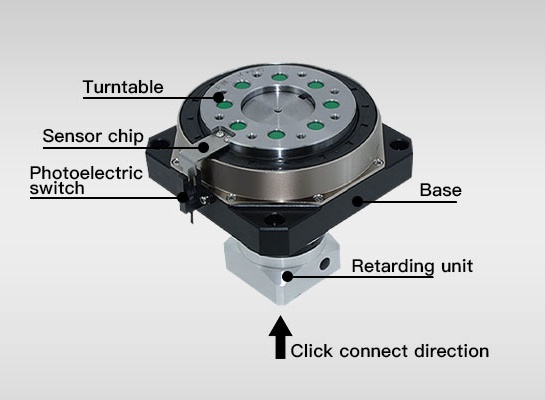

High rigidity

The turntable of the CR series servo rotary platform is supported by a set of precision crossed roller bearings. The rollers in the bearings are staggered at 90 degrees, and the roller diameter is slightly larger than the raceway size between the inner and outer rings of the bearings. This allows a preload to exist between the inner and outer rings and rollers of the crossed roller bearings. The turntable of the servo rotary platform supported by the bearings can withstand various moments such as radial, axial, and overturning forces. Its rigidity is more than 10 times that of traditional bearings.

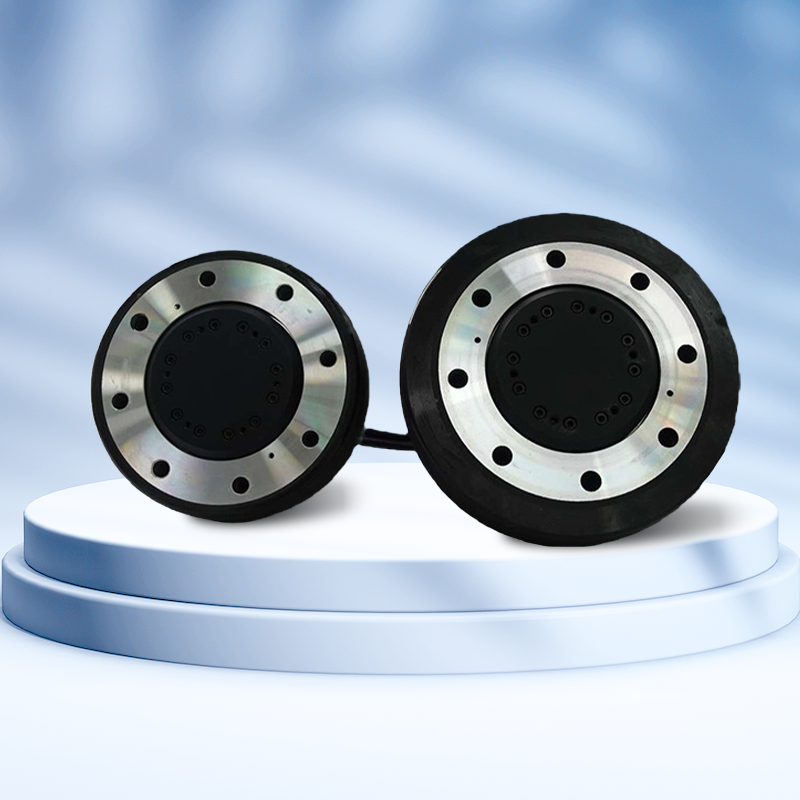

High rotation accuracy

After the CR series servo rotary platform is assembled, the outer diameter and end surface of the turntable are ground again with the cross roller bearing of the platform as the rotation center to ensure the coaxiality, end runout and other geometric tolerances of the turntable.

Large torque, low backlash

The CR series servo rotary platform uses planetary reduction to increase the output torque. The reduction ratio ranges from 1 to 512, and the output torque range is large, which can meet various torque requirements. In addition, the sun gear in the planetary reduction mechanism contacts the three row teeth at the same time, and the advanced gear grinding process makes the reverse backlash of the CR series servo rotary platform reach 3 arc minutes.

Built-in zero point switch, optional limit switch

The CR series servo rotary platform comes with a photoelectric switch and sensor as standard, and optional positive and negative limit switches to facilitate zero point control in electrical applications and simplify the mechanical design process.

Dustproof and waterproof

The CR series servo rotary platform uses a skeleton oil seal to isolate the inside of the platform from the outside. The dustproof and waterproof level reaches IP65, meeting the requirements of working in harsh environments such as dust, splashing water, and heavy humidity.

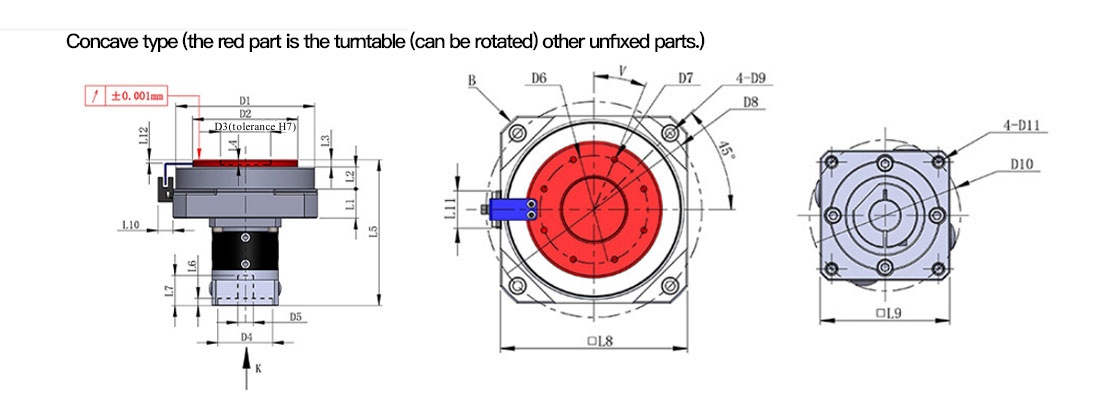

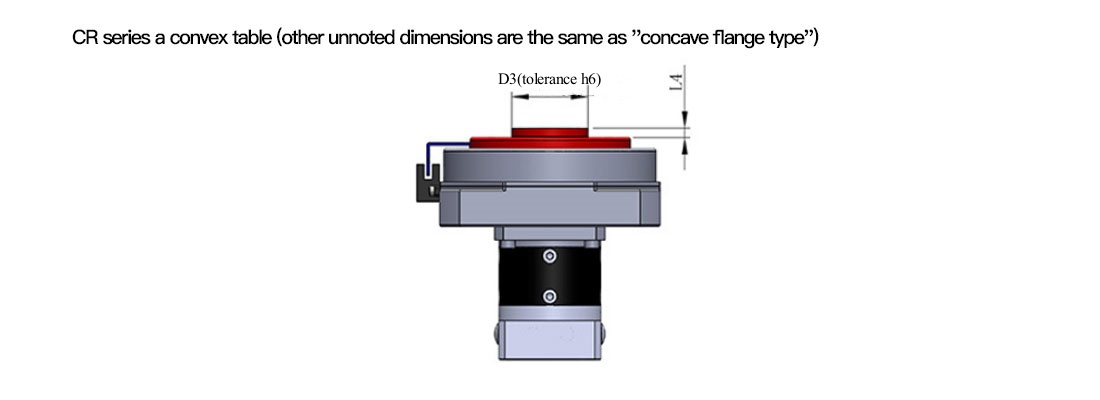

Dimensional drawing

Product Model | CR40 | CR60 | CR80 | CR120 | CR160 | CR250 | Reduction ratio/Number of stages | ||

Design load bearing | 15Kg | 40Kg | 80Kg | 200Kg | 800Kg | 3500Kg | |||

D1 | Boss diameter | Φ | 98 | 125 | 172 | 220 | 250 | 558 | |

D2 | Turntable diameter | Φh7 | 75 | 95 | 130 | 170 | 200 | 480 | |

D3 | Inner diameter of turntable | ΦH7 | 30 | 45 | 70 | 80 | 105 | 330 | |

D4 | Motor positioning circle diameter | ΦG7 | 30 | 50 | 70 | 110 | 114.3 | 114.3 | |

D5 | Motor shaft hole | ΦF7 | 8 | 14 | 19 | 22 | 35 | 35 | |

D6 | Turntable screw hole distribution circle | Φ | 59 | 75 | 106 | 138 | 160 | 430 | |

D7 | Turntable screw hole | 8-M4↓8 | 8-M5↓10 | 10-M6↓12 | 12-M8↓16 | 12-M10↓20 | 24-M12↓24 | ||

D8 | Base screw hole distribution circle | Φ | 120 | 150 | 205 | 265 | 300 | 650 | |

D9 | Base screw hole | Φ5.5 Through Hole | Φ6.6 Through Hole | Φ9 Through Hole | Φ11 Through Hole | Φ14 Through Hole | Φ22 Through Hole | ||

D10 | Motor screw hole distribution circle | Φ | 45 | 70 | 90 | 145 | 200 | 200 | |

D11 | Motor screw hole | M4↓8 | M4↓8 | M5↓10 | M8↓16 | M12↓24 | M12↓24 | ||

L1 | Base thickness | 22.3 | 26.3 | 30.3 | 40.3 | 45.3 | 57 | ||

L2 | Boss thickness | 17.7 | 19.7 | 24.7 | 29.7 | 31.7 | 50 | ||

L3 | Turntable protrusion | 6.5 | 6.5 | 9 | 12.5 | 18.5 | 12 | ||

L4 | Inner circle depth of turntable | 4 | 5 | 6 | 8 | 10 | 12 | ||

L5 | Overall length of platform | 112 | 135 | 164.5 | 207 | 263.5 | 292 | Level 1 | |

126.5 | 150 | 182 | 230.5 | 303 | 336.5 | Level 2 | |||

141 | 164.5 | 199.5 | 252.5 | 341.5 | 370.5 | Level 3 | |||

L6 | Motor positioning circle depth | 3.5 | 4 | 5 | 8 | 5 | 5 | ||

L7 | Motor shaft hole depth | 27 | 32 | 41 | 60 | 83 | 83 | ||

L8 | Base side length | 105 | 130 | 180 | 225 | 260 | 560 | ||

L9 | Motor side length | 40 | 60 | 80 | 130 | 180 | 180 | ||

L10 | Switch thickness | 13.4 | 13.4 | 13.4 | 13.4 | 13.4 | 13.4 | ||

L11 | Switch width | 26 | 26 | 26 | 26 | 26 | 26 | ||

L12 | Sensor plate position | 3 | 3 | 4 | 4 | 4 | 1 | ||

V | Hole Angle | 22.5° | 22.5° | 0° | 15° | 15° | 7.5° | ||

B | Platform chamfer | Φ | 135 | 168 | 230 | 295 | 340 | 735 |

Product parameters

Product model | CR40 | CR60 | CR80 | CR120 | CR160 | CR250 | Reduction ratio | Number of stages |

Rated output torque (Nm) | 8 | 18 | 40 | 125 | 400 | 1050 | 3 | Level 1 |

18 | 40 | 110 | 260 | 800 | 1780 | 4 | ||

16 | 36 | 90 | 230 | 700 | 1600 | 5 | ||

5 | 15 | 50 | 120 | 450 | 950 | 8 | ||

8 | 18 | 40 | 125 | 400 | 1050 | 9 | Level 2 | |

18 | 40 | 110 | 260 | 800 | 1780 | 12 | ||

16 | 36 | 90 | 230 | 700 | 1600 | 15 | ||

18 | 40 | 110 | 260 | 800 | 1780 | 16 | ||

18 | 40 | 110 | 260 | 800 | 1800 | 20 | ||

16 | 36 | 90 | 230 | 700 | 1780 | 25 | ||

18 | 40 | 110 | 260 | 800 | 1800 | 32 | ||

16 | 36 | 90 | 230 | 700 | 1600 | 40 | ||

5 | 15 | 50 | 120 | 450 | 1000 | 64 | ||

18 | 40 | 110 | 260 | 800 | 1780 | 60 | Level 3 | |

18 | 40 | 110 | 260 | 800 | 1780 | 80 | ||

18 | 40 | 110 | 260 | 800 | 1780 | 100 | ||

16 | 36 | 90 | 230 | 700 | 1780 | 120 | ||

18 | 40 | 110 | 220 | 800 | 1780 | 160 | ||

16 | 36 | 90 | 230 | 700 | 1600 | 200 | ||

18 | 40 | 110 | 260 | 800 | 1780 | 256 | ||

16 | 36 | 90 | 230 | 700 | 1600 | 320 | ||

5 | 15 | 50 | 120 | 450 | 1000 | 512 | ||

Fault stop torque | 2 times rated output torque | |||||||

Product Model | CR40 | CR60 | CR80 | CR120 | CR160 | CR250 | Number of stages | |

Maximum radial force (N) | 5800 | 6700 | 11000 | 16300 | 26700 | 116000 | / | |

Maximum axial force (N) | 5800 | 6700 | 11000 | 16300 | 26700 | 116000 | / | |

Design load bearing (kg) | 15Kg | 40Kg | 80Kg | 200Kg | 800Kg | 3500Kg | / | |

Maximum overturning moment (NM) | 435 | 636 | 1430 | 2771 | 5340 | 55680 | / | |

Full load efficiency (%) | 96 | Level 1 | ||||||

94 | Level 2 | |||||||

90 | Level 3 | |||||||

Average lifespan (h) | 20000 | |||||||

Weight (Kg) | 2.2 | 4.4 | 11 | 21.4 | 41.8 | Level 1 | ||

2.3 | 4.6 | 11.3 | 23.3 | 46.8 | Level 2 | |||

2.4 | 4.8 | 11.8 | 25.3 | 51.8 | Level 3 | |||

Product Model | CR40 | CR60 | CR80 | CR120 | CR160 | CR250 | Reduction ratio |

Moment of Inertia(kg·cm²) | 0.034 | 0.15 | 0.856 | 2.922 | 13.489 | 80.934 | 3 |

0.023 | 0.099 | 0.553 | 1.902 | 8.266 | 49.596 | 4 | |

0.02 | 0.081 | 0.468 | 1.591 | 6.313 | 37.878 | 5 | |

0.017 | 0.066 | 0.396 | 1.341 | 4.702 | 28.212 | 8 | |

0.03 | 0.133 | 0.749 | 2.652 | 12.29 | 73.74 | 9 | |

0.029 | 0.128 | 0.725 | 2.578 | 12.456 | 74.736 | 12 | |

0.023 | 0.077 | 0.713 | 2.541 | 12.405 | 74.43 | 15 | |

0.022 | 0.088 | 0.502 | 1.757 | 7.499 | 44.994 | 16 | |

0.019 | 0.075 | 0.441 | 1.504 | 6.667 | 40.002 | 20 | |

0.019 | 0.075 | 0.441 | 1.492 | 5.819 | 34.914 | 25 | |

0.017 | 0.064 | 0.39 | 1.301 | 6.366 | 38.196 | 32 | |

0.016 | 0.064 | 0.39 | 1.301 | 5.283 | 31.698 | 40 | |

0.016 | 0.064 | 0.39 | 1.3 | 4.501 | 27.006 | 64 | |

0.029 | 0.076 | 0.51 | 2.571 | 7.502 | 45.012 | 60 | |

0.019 | 0.075 | 0.5 | 1.5 | 7.501 | 45.006 | 80 | |

0.019 | 0.075 | 0.44 | 1.49 | 7.401 | 44.406 | 100 | |

0.029 | 0.064 | 0.7 | 2.5 | 7.301 | 43.806 | 120 | |

0.016 | 0.064 | 0.39 | 1.3 | 6.5 | 39 | 160 | |

0.016 | 0.064 | 0.39 | 1.3 | 6.2 | 37.2 | 200 | |

0.016 | 0.064 | 0.39 | 1.3 | 5.7 | 34.2 | 256 | |

0.016 | 0.064 | 0.39 | 1.3 | 5.4 | 32.4 | 320 | |

0.016 | 0.064 | 0.39 | 1.3 | 5.2 | 31.2 | 512 | |

Return clearance | <3 arc minutes | <3 arc minutes | <3 arc minutes | <3 arc minutes | <3 arc minutes | <3 arc minutes | Level 1 |

<5 arc minutes | <5 arc minutes | <5 arc minutes | <5 arc minutes | <5 arc minutes | <5 arc minutes | Level 2 | |

<8 arc minutes | <8 arc minutes | <8 arc minutes | <8 arc minutes | <8 arc minutes | <8 arc minutes | Level 3 |

Product Model | CR40 | CR60 | CR80 | CR120 | CR160 | CR250 |

Turntable end runout | ±0.001 | ±0.001 | ±0.001 | ±0.001 | ±0.001 | 士0.01 |

Radial runout of turntable | ±0.001 | ±0.001 | ±0.001 | ±0.001 | ±0.001 | 士0.01 |

Torsional rigidity | 0.7 | 1.8 | 4.4 | 9.2 | 26.7 | 58 |

Noise | 55 | 58 | 60 | 65 | 70 | 80 |

Rated input speed | 4500 | 4000 | 4000 | 3500 | 3000 | 3000 |

Rated output speed | 300 | 300 | 300 | 300 | 300 | 300 |

Selection calculation

I. Selection steps

1. According to the actual installation requirements and accuracy requirements, select one of the models CR, SR, and RR

2. Calculate the load inertia, and calculate the acceleration torque according to the speed. Refer to the "Rated output torque" column in the sample book table to select the size that meets the torque requirements

3. According to the total load weight, refer to the "Design load-bearing" column in the sample book table, and select the appropriate size in combination with the torque requirements

4. Select the motor according to the size of the rotating platform

5. According to the load inertia and the motor rotor inertia, calculate the minimum reduction ratio required to meet the inertia matching

6. According to the acceleration torque and motor torque, calculate the minimum reduction ratio to meet the torque requirements

7. According to the actual speed requirements and the rated speed of the motor, calculate the maximum reduction ratio to meet the speed requirements

8. According to the three calculated reduction ratios, select the appropriate reduction ratio according to the reduction ratio table attached to the sample book

9. According to the needs, select a concave edge turntable or a convex platform turntable, and the selection is over

II. Selection Example

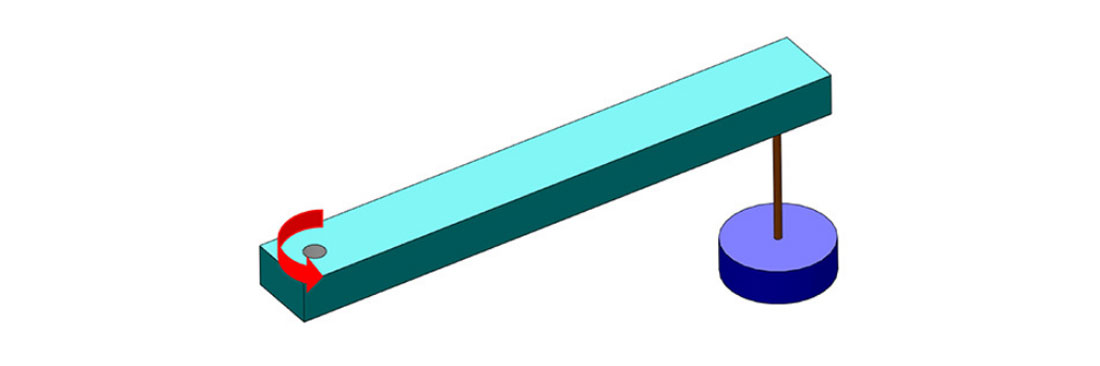

Example 1: Make a four-station indexing plate, total load weight: 20KG, load diameter 400mm, load speed: 90 degrees per second, required repeatability: plus or minus 0.02mm, this device is installed on the XY cross platform, and the height dimension of the rotating platform cannot be too large

Calculation is as follows:

1. The repeatability of plus or minus 0.02 is a high-precision requirement, so only SR or RR can be selected. The height dimension cannot be too large, so only the RR series rotating platform can be selected

2. According to the load weight and size, the load inertia is calculated as: 0.4kgM², the acceleration time is set to 0.1 seconds, the uniform speed time is: 0.8 seconds, the deceleration time is: 0.1 seconds, and the acceleration torque is calculated to be: 6.98NM. The models that meet this torque requirement are: SR40, SR60, SR80, SR120, SR160, SR250.

3. The total load weight is: 20KG. According to the "Design Load-bearing" table in the sample book, the load-bearing capacity of RR60 is: 40KG, which meets the requirements

4. The motor interface length of RR60 is: 60mm, so a 400W servo motor is selected. In this example, a Panasonic 400W servo motor (high inertia) is selected

5. According to the load inertia (0.4kgM²) and the 400W (high inertia) Panasonic servo inertia (0.000067kgM²), the load inertia is not greater than 15 times the motor inertia, and the minimum reduction ratio required to meet the inertia matching is calculated as: 19.95

6. According to the acceleration torque (6.97NM) and the rated torque of the 400W servo motor (1.3NM), the minimum reduction ratio that meets the torque requirement is calculated as: 5.4

7. According to the required speed (90 degrees per second) and the rated speed of the 400W servo (3000 revolutions per minute), the maximum reduction ratio that meets the speed requirement is calculated as: 180

8. Combined with the three reduction ratio limit ranges, refer to the reduction ratio listed in the sample book, and select the reduction ratio as: 24

9. According to the installation requirements, select the concave edge turntable, and finally determine the model as: RR60-24W

Example 2: Make a robotic arm with an arm length of 1.3m and an arm weight of 22KG. The weight of the workpiece to be grabbed is: 1.5KG. The required speed is 90 degrees per second. Precise positioning is required, and the motor is installed downward.

The calculation is as follows:

1. Precise positioning is required, so only SR or RR can be selected: the motor is required to be installed downward, so only the SR series rotary platform can be selected

2. The load inertia is composed of the cantilever inertia and the workpiece inertia: 12.39+2.54=14.93kgM², the acceleration time is set to 0.1 seconds, the uniform speed time is: 0.8 seconds, the deceleration time is: 0.1 seconds, and the calculated acceleration torque is: 260.4NM. The models that meet this torque requirement are: SR80, SR120, SR160

3. The total load weight is: 22+1.5=23.5KG. According to the "Design Load-bearing" table column in the sample book, SR60, SR80, SR120, SR160, SR250

all meet the requirements. Combined with the torque requirements, it is more appropriate to choose SR80

4. The motor interface length of SR80 is: 80mm, so a 750W servo motor is selected. In this example Select Panasonic 750W servo motor (high inertia)

5. According to the load inertia (14.93kgM²) and the 750W (high inertia) Panasonic servo inertia (0.000151kgM²), the load inertia is not greater than 15 times the motor inertia, and the minimum reduction ratio required to meet the inertia matching is calculated to be: 81.2

6. According to the acceleration torque (260.4NM) and the 750W servo motor torque (2.4NM), the minimum reduction ratio to meet the torque requirement is calculated to be: 108.5

7. According to the required speed (90 degrees per second) and the rated speed of the 750W servo (3000 revolutions per minute), the maximum reduction ratio to meet the speed requirement is calculated to be: 180

8. Combined with the three reduction ratio limit ranges, refer to the reduction ratio listed in the sample book, and select the reduction ratio: 120

9. According to the installation requirements, select the concave edge turntable, and finally determine the model: SR80-120W

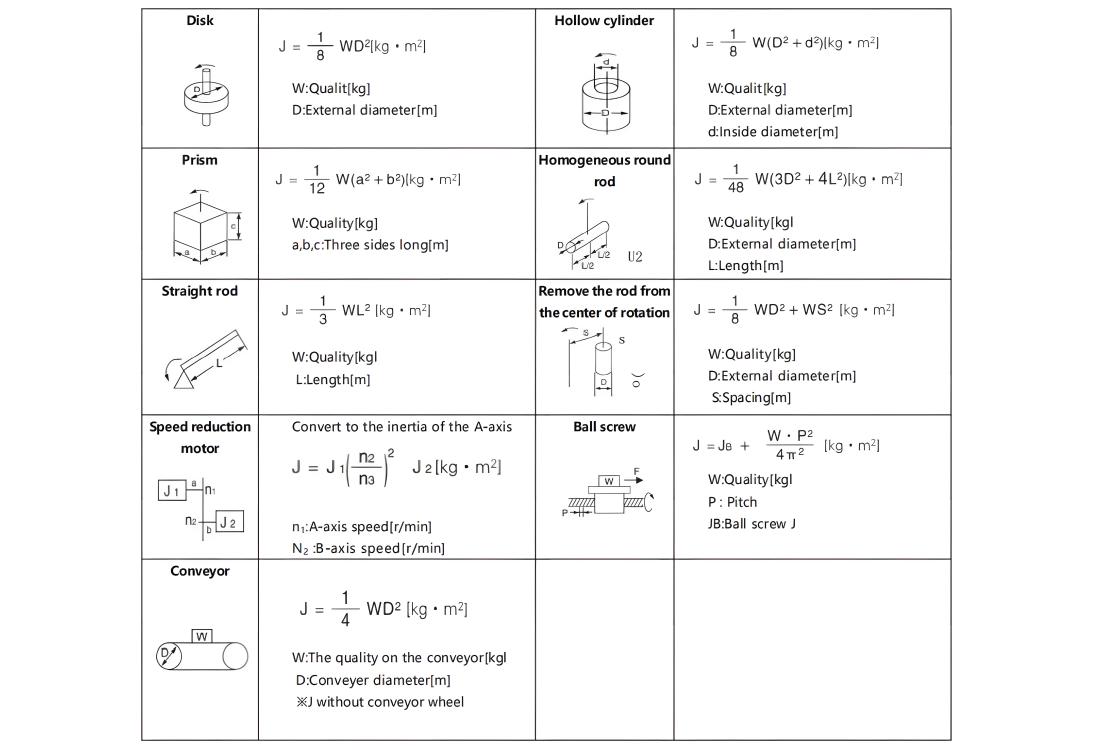

III.Common inertia calculation formulas

Application

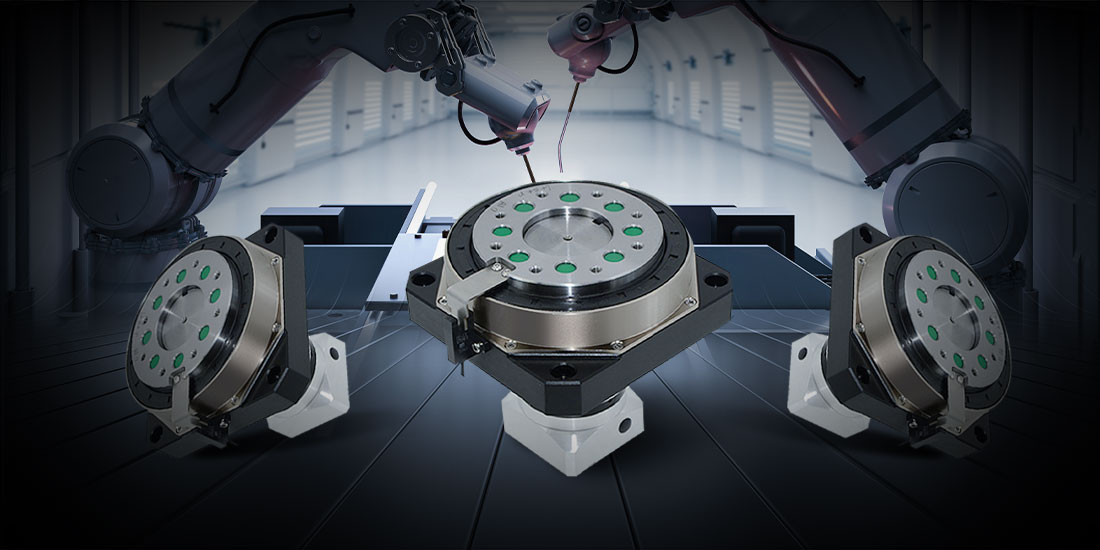

Industrial Automation: In the automated welding production line of automobile manufacturing, the CR series hollow rotating platform is installed on the joints of the welding robot. With its precise rotation, the welding tool can flexibly adjust the angle, accurately locate the welding point, and improve the welding quality and efficiency. Its internal hollow structure facilitates the passage of cables and air pipes to avoid line entanglement.

Electronic Manufacturing: In the mobile phone motherboard inspection link, the CR series hollow rotating platform carries the motherboard. With high-precision rotation, high-resolution cameras and sensors, it can perform 360-degree scanning of the tiny components of the motherboard without dead angles, accurately detect circuit defects and component welding problems, and improve detection efficiency and accuracy.

Medical Equipment: In CT scanners, the CR series hollow rotating platform carries the X-ray source and detector system, accurately controls the rotation angle and speed, rotates around the patient, and obtains tomographic image data from multiple perspectives to help doctors make accurate diagnoses.

Quality Assurance

Product design and development: During the design phase of the central control rotary platform, a team of professional engineers gathered together to use advanced computer-aided design (CAD) and simulation analysis software to perform fine simulation and optimization of core parts such as product structure, power transmission, and control logic to ensure the reliability and stability of product performance from the source. All design plans must undergo multiple rounds of internal review and test verification before they can enter the production stage.

Raw material procurement: Strictly screen raw material suppliers to establish long-term, stable and high-standard cooperative relationships. For each batch of raw materials, strict quality inspections are carried out, covering the composition analysis of metal materials, mechanical performance testing, electrical parameter testing of electronic components, reliability testing, etc. Only raw materials that meet or exceed industry standards will be allowed to be put into production to ensure the basic quality of the product.

Production process control: The production workshop operates in accordance with a strict quality management system, introduces automated production equipment and high-precision testing instruments, and realizes the standardization and refinement of the production process. At each key node of production, quality inspection points are set up to conduct real-time sampling and full inspections of semi-finished products, including component processing accuracy inspection, assembly quality inspection, and initial electrical performance testing. For quality problems that occur during the production process, the traceability and rectification mechanism is immediately activated to ensure that the problematic products do not flow into the next link.

Finished product inspection: Each central control rotary platform must undergo a comprehensive and rigorous finished product inspection process before leaving the factory. Inspection items include but are not limited to no-load operation test, full-load operation test, positioning accuracy test, repeated positioning accuracy test, noise and vibration test, electrical safety performance test, etc. Only equipment whose indicators fully meet the product quality standards will be labeled as qualified and allowed to leave the factory.

After-sale guarantee

If a product fails, our after-sales team will respond immediately and quickly arrange for professional technicians to communicate with you to understand the details of the failure. We will provide you with remote technical guidance and assist you in solving the problem according to the specific situation. At the same time, we also provide you with regular return visits to understand the use of the product and collect your opinions and suggestions in order to continuously optimize products and services. When the product is upgraded, we will also notify you in a timely manner and provide you with corresponding technical support and solutions to keep your equipment in good performance.