Product Description

Precision Digital Pressure Sensor Transmitter: High-precision, durable, and accurate pressure monitoring with ceramic technology, ideal for industrial and engineering applications. Designed to withstand harsh environments, it provides reliable real-time data for process control, ensuring optimal performance and efficiency. With advanced digital output, it delivers precise measurements, reducing the risk of errors in critical systems. This transmitter is perfect for use in diverse industries such as manufacturing, automation, and oil & gas, offering long-lasting reliability and consistent results.

Product parameters

Measuring range | 0...2bar...6bar...10bar...16bar...25bar...30bar (All available) | ||

Overload safety | 2-fold rated pressure | ||

Pressure type | Gauge pressure | ||

Measurement medium | Gas or liquid which is compatible with stainless steel | ||

Measurement accuracy | ±1%FS; ±0.5%FS; | ||

Long - term stability | ≤ ± 0.3% FS/year | ||

Operating temperature | - 40℃...+125℃ | ||

Zero temperature coefficient | Typical: ± 0.03% FS / ℃; Maximum: ± 0.05% FS / ℃ | ||

Temperature coefficient sensitivity | Typical: ± 0.03% FS / ℃; Maximum: ± 0.05% FS / ℃ | ||

Signal and power | Optional signal | Output signal | Supply voltage |

Current (2-wire) | 4...20mA | DC 8...32V | |

Ratio voltage (3-wire) | DC 0.5...4.5V | DC 5V±10% | |

* Other output signals could be provided | |||

Load in Ω | Current (two wires): ≤ [(supply voltage -7.5v) /0.02A] | ||

Voltage (three wires): ≥10k | |||

Total current consumption | Current (2-wire system): Signal current, max. 25mA | ||

Voltage (3-wire system): ≤5mA | |||

Impact resistance | 100g, half sine of final peak serrated ladder type, runs for 6 ms | ||

Anti-vibration | ≤ ± 0.1% FS (X, Y, Z axis, 200Hz / g) | ||

Insulation resistance | > 100MΩ 500Vdc after applying voltage | ||

Resolution | Infinitesimal (theoretical), 1/100000 (usually) | ||

Response time | ≤ 2ms | ||

Weight | Approx. 38g without cable | ||

Ingress protection | IP65 | ||

Electromagnetic Compatibility | EN50081-1;EN50082-2;IEC61000-4-3 | ||

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Component Fabrication & Assembly

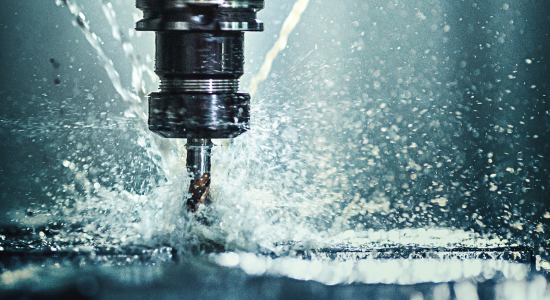

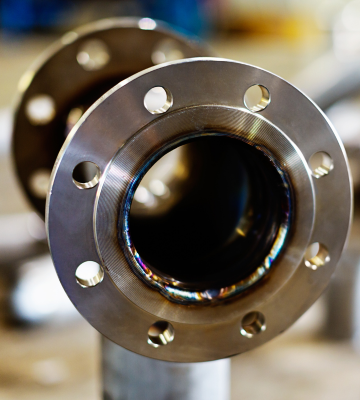

Precision machining of components, including ceramic pressure sensing elements, followed by careful assembly to ensure optimal functionality.

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

The quality control of the Precision Digital Pressure Sensor Transmitter involves a comprehensive process to ensure accuracy, reliability, and durability. Every unit undergoes rigorous testing at multiple stages of production, starting with thorough material inspection to ensure that only high-quality components are used. Advanced calibration techniques are employed to verify precise pressure measurement accuracy. Each transmitter is subjected to environmental stress tests to simulate real-world conditions and ensure its performance in harsh industrial environments.

Processing capability

The processing capability of the Precision Digital Pressure Sensor Transmitter is driven by advanced manufacturing technologies that ensure high-precision production. Utilizing state-of-the-art machinery, the process involves precise component fabrication, including ceramic pressure sensing elements, followed by careful assembly and calibration. The use of automated systems and real-time monitoring ensures consistent accuracy and quality at every stage of production.

Additional processes