Product Description

The core structure of the professional-grade robot arm electric gripper is made of aviation-grade high-strength alloy material, which has both lightweight characteristics and super impact resistance, reducing mechanical load while ensuring stable operation. The surface is treated with wear-resistant technology, and high-frequency grasping friction is not easy to wear and tear, extending the service life; it also has corrosion-resistant properties, easily copes with complex environments such as industrial dust and oil pollution, and always maintains precise grasping performance. From structural strength to environmental adaptability, the material advantages build a long-term and stable foundation for automated operations.

Product parameters

Parameter name | Parameter value | Parameter name | Parameter value |

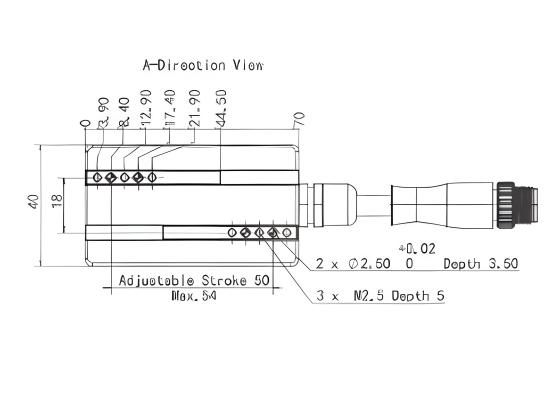

Adjustable stroke | 0-50 mm | Rated voltage | DC24±10%V |

One finger clamping force | 2-60 N | Maximum current | 0.85A |

Open/close time | 0.6s | Rated current | 0.4A |

Position repeatability | ± 0.02 mm | Communication protocol | Modbus RTU (RS485) Digital I/O optional |

Maximum recommended load | 1 kg | Complies with international standards | CE, RoHS |

Drop detection | Support | Allowable static load in vertical direction Fz | 200N |

Applicable environment | 5-40℃ 85%RH or less | Allowable static torque of slider Mx | 2Nm |

Operation noise | Less than 40 dB | Allowable static torque of slider | 1.5Nm |

Weight | 0.57 kg | Allowable static torque of slider Mz | 2Nm |

IP rating | IP40, IP65 option a |

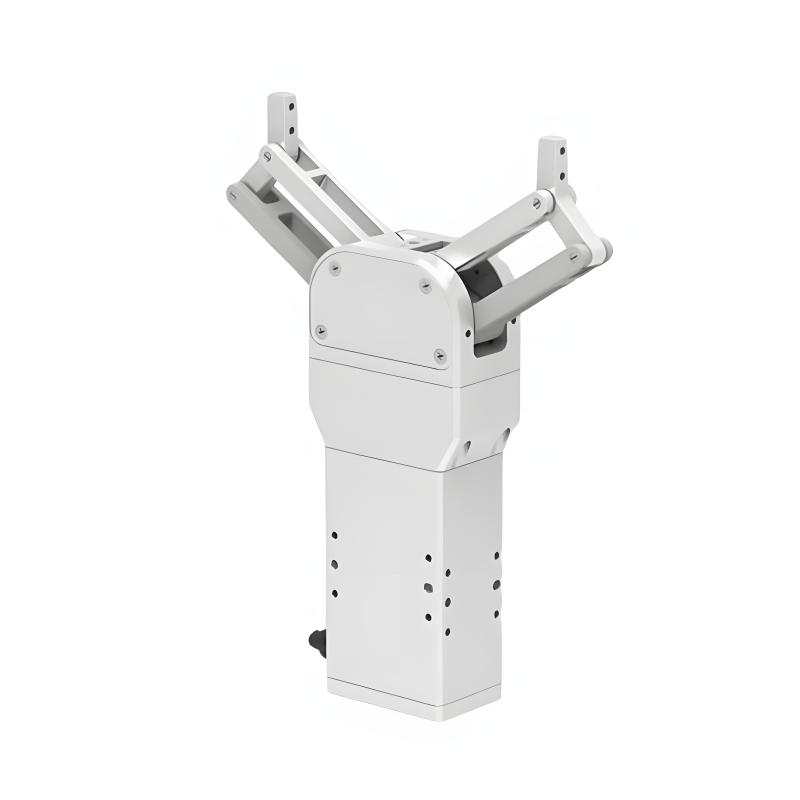

Product Display

High-strength material

Made of aviation-grade alloy, wear-resistant, impact-resistant, and corrosion-resistant, it can cope with high-frequency industrial use.

Precise control

Precision drive system, achieves millimeter-level precision grasping, stable operation without offset.

Flexible adaptation

Double-finger structure design, compatible with a variety of material grasping, adaptable to automation scenarios such as handling and assembly.

Efficient and durable

Long-term stable operation, reducing maintenance costs, and greatly improving the efficiency of robot production line operations.

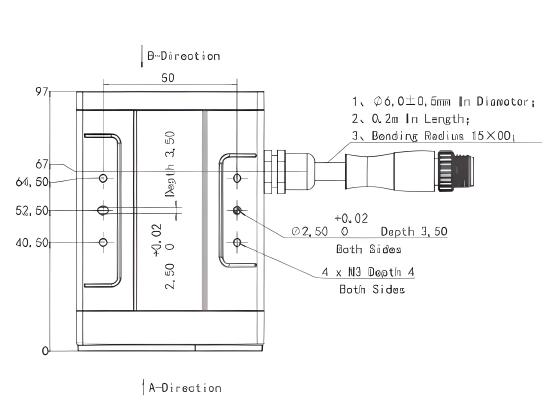

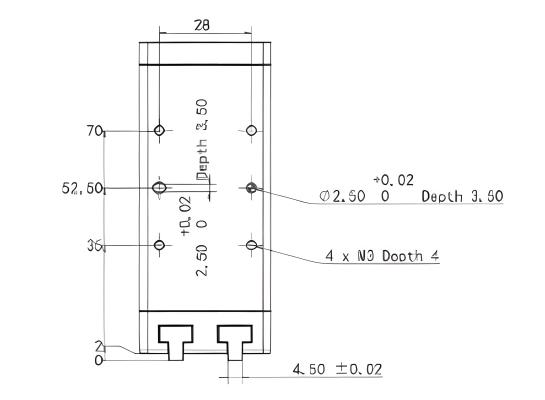

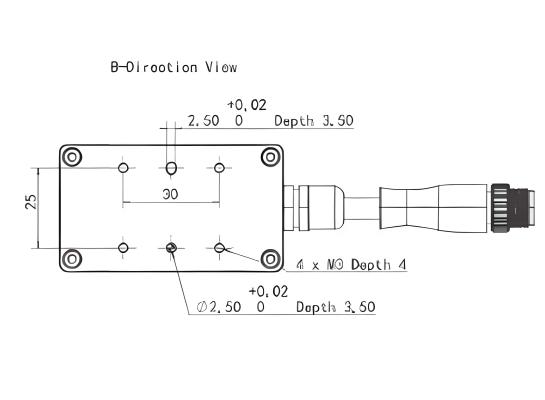

Size & Interface

Application Cases

3C Electronic Manufacturing: On mobile phone/computer production lines, precise grabbing of tiny components such as chips and capacitors to complete circuit board mounting and ensure high-precision assembly of electronic equipment.

Medical testing and pharmaceutical production: In laboratories or pharmaceutical factories, batch grabbing of test tubes and medicine boxes to complete sample sorting and medicine boxing to meet the cleanliness and precision requirements of medical scenarios.

Robotic motion demonstration: Simulating sports scenes, such as manipulating a robotic arm to play badminton, by flexibly grabbing the racket, demonstrating the dynamic control performance of the electric gripper, for technical demonstration or education and teaching.