Product Description

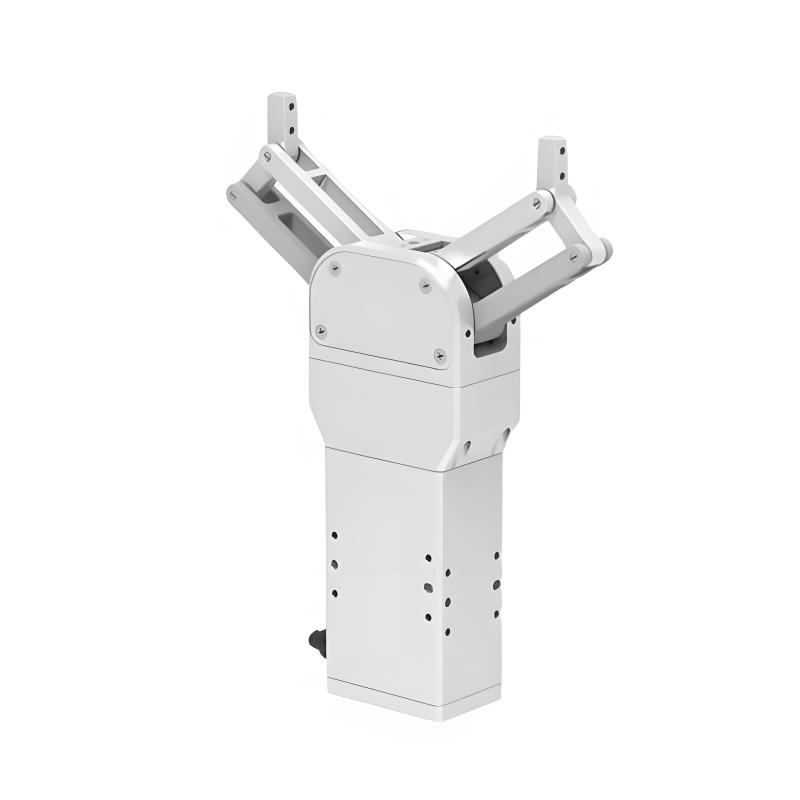

This compact electric gripper belongs to the precision intelligent electric actuator platform, and provides innovative linkage solutions, maintaining the high cost-effectiveness while upgrading materials. The product adopts a sophisticated appearance design, has a parallel opening and closing clamping function, and can stably adapt to different workpiece grasping requirements; with an integrated anti-collision structure, it improves durability and reliability; the operation process is accurate and stable, positioning is error-free, and the energy consumption is significantly lower than traditional air grippers, effectively reducing the cost of use, and bringing a new efficient, energy-saving, and stable clamping solution to automated production lines.

Product parameters

Description item | Parameter Description | ||

Model name | EGB-06L-16D | EGB-06H-16D | EGB-06L-20D |

Size number | 06L | 06H | 06L |

Stroke (mm) | 6 | 6 | 10 |

Clamping force ¹ (N) | 10/20/30/40 | 10/15/35/60 | 6/30/60/85 |

Absolute positioning position (mm) | 0/2/4 | 0/2/4 | 0/4/8 |

Repeat accuracy (mm) | ±0.02 | ±0.02 | ±0.02 |

Fastest opening/closing time (s) | 0.3/0.3 | 0.1/0.1 | 0.18/0.18 |

Load allowable torque (N.m) | MR:1.36, MP:0.8, MY:0.68 | MR:1.36, MP:0.8, MY:0.68 | MR:2.65, MP:2.35, MY:1.65 |

Controller | Built-in | Built-in | Built-in |

Control mode (bus) | Modbus RTU | Modbus RTU | Modbus RTU |

Control mode (interface) | I/O control | I/O control | I/O control |

I/O interface | Input 3 points (NPN) | Input 3 points (NPN) | Input 3 points (NPN) |

Rated voltage (V) | DC24±10% | DC24±10% | DC24±10% |

Rated current (A) | 0.3 | 0.3 | 0.4 |

Peak current (A) | 0.6 | 0.6 | 0.8 |

Mass (kg) | 0.22 | 0.22 | 0.32 |

Usage environment | 0~40℃, 85% RH or less | 0~40℃, 85% RH or less | 0~40℃, 85% RH or less |

Protection level | IP40 | IP40 | IP40 |

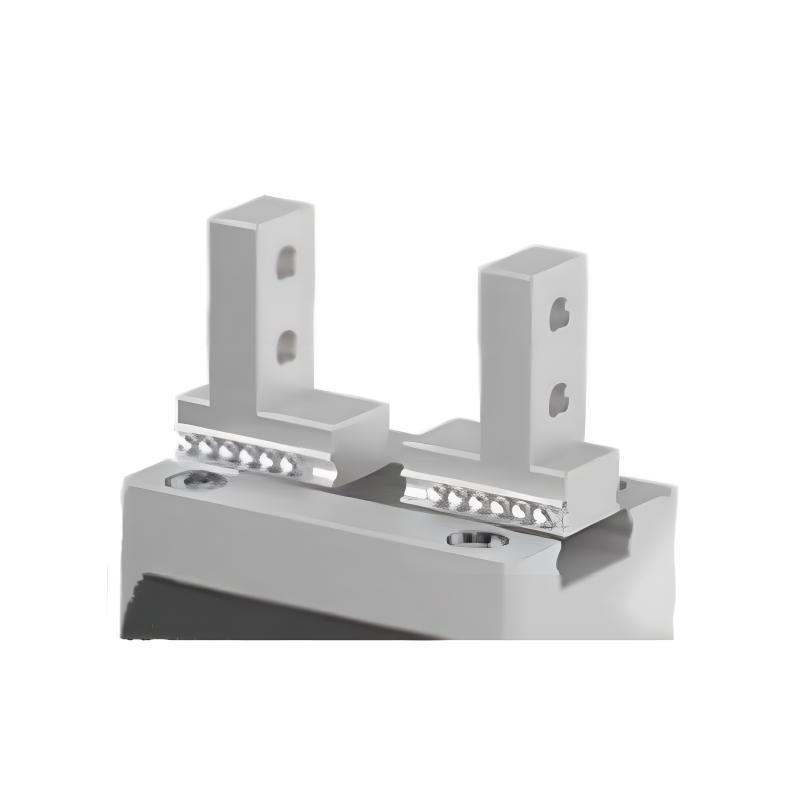

Product Display

No debugging required, plug and play

EGB internal integrated servo system

Replaces air compressor + filter + solenoid valve + throttle valve + pneumatic finger

No need to replace the fixture

No need to worry about air leakage

No switch slot required

No magnetic switch required

Active performance and flexible use

Large clamping force range 10-85/N

High repeatability accuracy ±0.02mm

Fast opening and closing speed 0.3-0.18/S

Rich opening and closing stroke 6-10mm

Multi-face installation design

Clamps can be designed by yourself

Application Cases

In 3C electronics manufacturing, when it comes to assembling tiny precision components such as chip patches and camera modules, compact parallel electric grippers take advantage of their precise parallel clamping to achieve zero-deviation grasping and placement, avoiding the jitter defects of traditional air grippers. When used in automotive parts production lines, their rapid response and stable operation characteristics allow them to efficiently complete repetitive grasping tasks in high-frequency assembly scenarios of screws and gears, and their energy consumption is significantly lower than that of air grippers, reducing production line operating costs. In the assembly of precision instruments, their compact structure saves equipment space, and combined with their precise positioning capabilities, they can operate flexibly even in narrow workstations, ensuring the assembly accuracy of fine components such as optical lenses. With their core advantages of "high precision, low energy consumption, and easy adaptability", they can comprehensively improve the efficiency of automated production.