Product Description

Die cutting mold and punching pin equipment made from high-speed steel, designed for strength, durability, and high precision. Ideal for various industrial applications, it supports all types of metal punching and forming tasks with consistent performance.

Product parameters

Item | Value |

CNC Machining or Not | CNC Machining |

Material Capabilities | ทองเหลือง, อะลูมิเนียม, ทองแดง, ทองแดงหล่อ, โลหะแข็ง, โลหะมีค่า, สแตนเลส, โลหะผสมเหล็ก, อื่นๆ |

Type | Milling |

Micro Machining or Not | Micro Machining |

Model | Metal CNC machining |

Brand | Reteck Model |

Tolerance | 0.005-0.01 |

Surface treatment | การ anodizing, การทรายพ่น, การพ่นสีผง, การพ่นสี |

File formats | PRT, STP, IGS, X-T, SLDPRT, STL, OBJ |

Quality control | การตรวจสอบ 100% ก่อนการจัดส่ง |

Production lead time | 5-7 วัน |

Delivery time | 3-5 วัน |

ODM high quality precision CNC machining services | บริการ OEM/ODM การกลึง CNC ความแม่นยำสูง |

Processing | ประเภท CNC machining |

OEM/ODM | การผลิต OEM/ODM การหล่อสูญญากาศ การสร้างต้นแบบรวดเร็ว การปรับแต่ง |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Metal Lockers and Furniture

commercial and industrial environments, sheet metal is ideal for creating secure, durable lockers and heavy-duty furniture. It can withstand wear and tear from daily use while providing a high level of security, making it a popular choice for schools, gyms, and workplaces.

Computers and Servers

Sheet metal is used in the construction of computer cases, server racks, and cooling systems. Its excellent heat dissipation properties help regulate temperature, protecting sensitive electronic components. Additionally, sheet metal offers strong structural support to safeguard delicate internal parts during handling or operatio

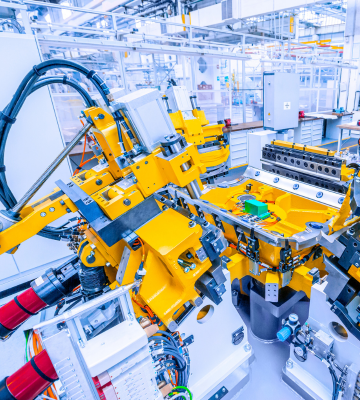

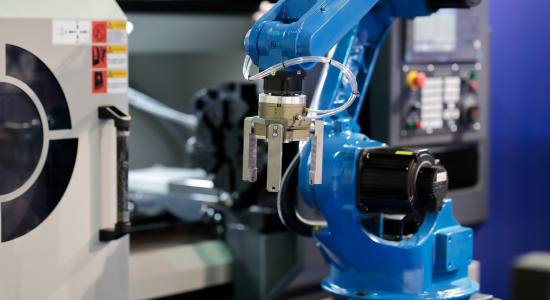

Industrial Machinery

Sheet metal is a critical material in the construction of industrial machinery, including components such as housings, panels, and structural supports. Its strength and ability to be precisely cut, bent, and welded allow manufacturers to produce robust machinery capable of handling heavy loads and extreme conditions

Material

Aluminum Alloy

Stainless Steel

Quality Control

Processing capability

Our processing capability for mold accessories and die cutting punch pins made from high-speed steel is designed to support high-precision manufacturing with tight tolerances and consistent quality. Utilizing advanced CNC machining, grinding, and heat treatment processes, we can produce punch pins in a wide range of sizes, shapes, and custom specifications. Our facilities are equipped to handle complex geometries and critical dimensions required for high-speed and high-load punching applications.

Additional processes