Product Description

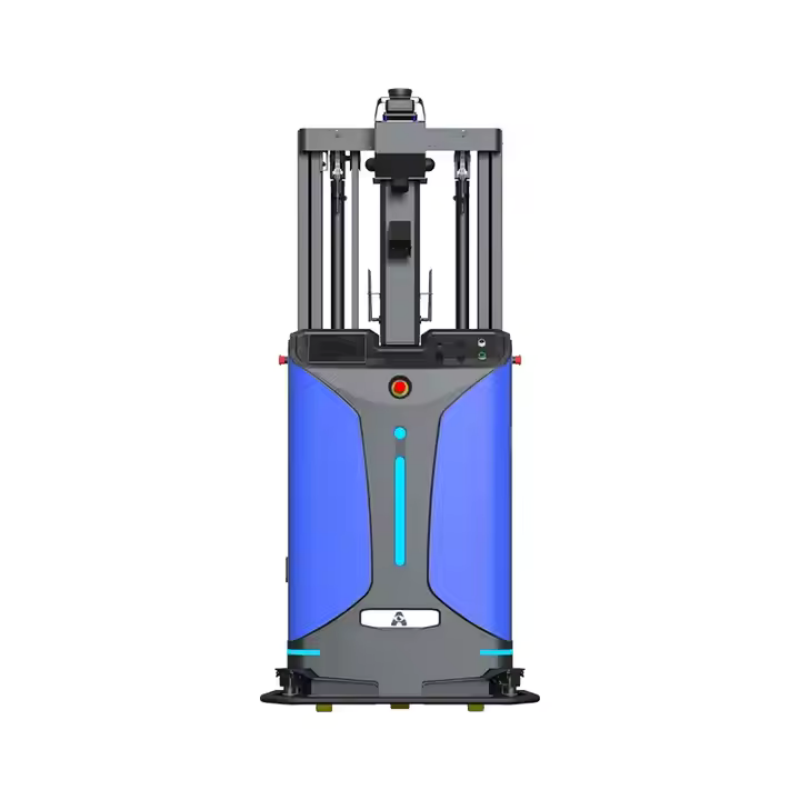

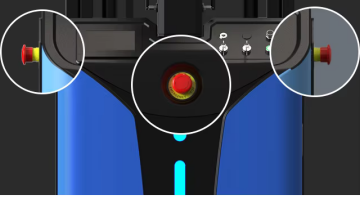

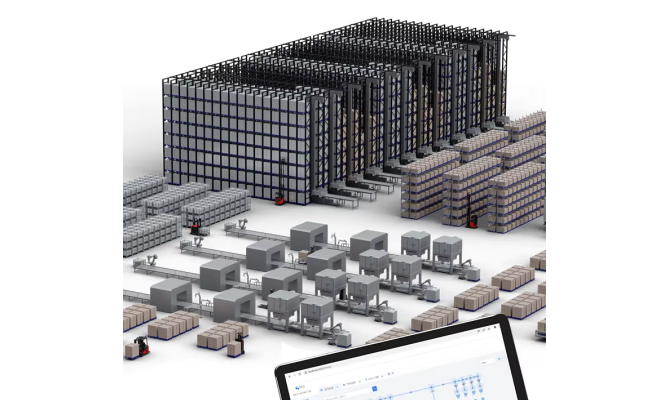

The AGV robot is designed to provide efficient and reliable material handling solutions for a variety of industries, including manufacturing plants, food and beverage factories, and the retail sector. Its rugged construction and high-quality components ensure seamless operation.

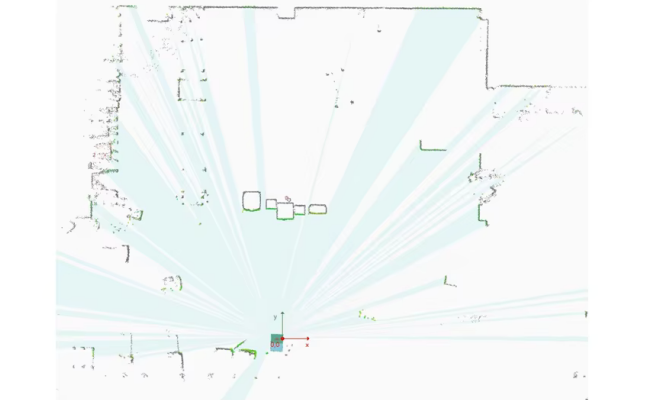

Advanced Navigation System: Equipped with a laser SLAM navigation system, the AGV robot provides precise positioning and navigation with an accuracy of 10mm, allowing precise control and efficient movement within a map area of up to 400,000 square meters.

Long-lasting Battery Life: The AGV robot uses high-capacity batteries with a cycle life of more than 2000 times, ensuring extended operating time and minimizing the need for frequent battery replacement. The battery specification is 24v/180Ah (lithium iron phosphate).

Product Features

This indoor mapping area navigation, relying on cutting-edge laser SLAM navigation technology, can accurately build indoor maps. Its powerful performance enables it to map an area of up to 400,000 square meters. Whether it is a large open venue or a complex commercial complex, industrial plant and other scenes, it can easily cope with it, providing reliable guarantee for indoor mapping work.

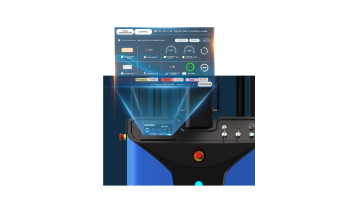

In modern complex operation scenarios, the unified management and scheduling system plays a key role. It can accurately coordinate the collaborative planning of multiple robots, and realize intelligent scheduling with the help of intelligent algorithms according to factors such as task type and environmental changes, so that each robot can cooperate efficiently, greatly improve overall operation efficiency, and reduce operating costs.

Application Cases

Technical Parameter

Technical Parameters | |||

Driving mode | Automatic navigation by manual control devce | Standard lifting height | 1600/3000mm |

Navigation type | Laser SLAM | Gantry height | 2130/3545mm |

Rated load capacity | 1400KG | Fork surface ground clearance (at lowest position) | 85+5mm |

Pallet type | 3-long-beam pallet | Length * width * height | 1220*180*70mm |

Load center distance | 600mm | Fork outer width | 555/570/680mm |

Selfweight (with battery) | 680/740kg | Comprehensive battery life | 10h |

Navigation and fork entry position accuracy | ± 10mm | Charging time | 2h |

Navigation angle accuracy | ± 0.5° | Charging method | Manual/Automatic |