Product Description

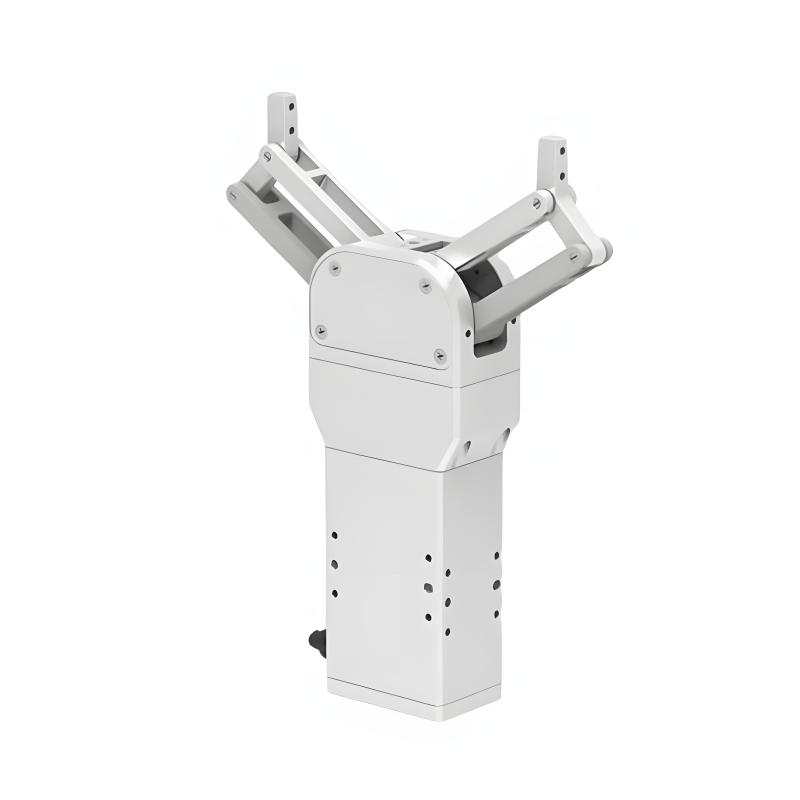

This series of grippers integrates rotation and gripping functions. The discrete control design makes them non-interfering and can accurately perform various operations. The torque control technology is adopted, which can adaptively clamp different workpieces and has strong adaptability. It has high-precision characteristics and accurate and reliable operation; it has super torque and super clamping force, which can stably grasp heavy objects. The unique slip ring-free structure improves the durability and stability of the equipment. The dual servo control further ensures the efficiency and accuracy of operation, realizes the integration of adaptive clamping and rotary clamping, and provides efficient and stable gripping solutions for industrial production and other scenarios.

Product parameters

Model name | RM-RGM-0606-360-16-02-ITG | RM-RGM-0606-360-32-04-ITG | RM-RGM-0609-360-32-08-ITG |

Adjustable stroke (mm) | 0-16 | 0-32 | 0-32 |

Clamping force ¹(N) | 4-24 | 30-100 | 30-100 |

Fastest opening/closing time (s) | 0.15/0.15 | 0.3/0.3 | 0.3/0.3 |

Slider static moment (N.m) | MR:1.5,MP:1.5,MY:1.5 | MR:2.1,MP:2.1,MY:2.1 | MR:2.1,MP:2.1,MY:2.1 |

Rated torque (N.m) | 0.2 | 0.4 | 0.8 |

Peak torque (N.m) | 0.35 | 1.2 | 1.5 |

Maximum allowable inertia (kg/mm²) | 100 | 200 | 200 |

Position repeatability ²(mm) | ±0.02 | ±0.02 | ±0.02 |

Rotation repeatability (°) | ±0.05 | ±0.05 | ±0.05 |

Minimum/maximum rotation angle | No restrictions | No restrictions | No restrictions |

Maximum rotation speed (°/s) | 1000 | 1100 | 2160 |

Controller | Built-in | Built-in | Built-in |

Supported bus protocol | Modbus RTU | Modbus RTU | Modbus RTU |

Rated voltage (V) | DC24±10% | DC24±10% | DC24±10% |

Rated current (A) | 1.8 | 1.8 | 2 |

Peak current (A) | 4 | 4 | 4 |

Mass (kg) | 0.42 | 0.7 | 1.1 |

Usage environment | 0 - 40°C, below 85% RH | 0 - 40°C, below 85% RH | 0 - 40°C, below 85% RH |

Protection level | IP40 | IP40 | IP40 |

Product Display

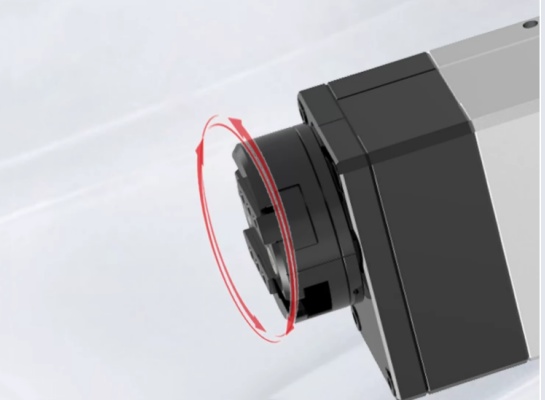

Unlimited rotation in forward and reverse directions

Adjustable torque and speed

Rotation repeatability up to ±0.5°, 360° unlimited rotation

Torque, position and speed can be controlled to achieve multi-stage motion.

Rotation and gripping in one

Separate control without mutual interference

Self-adaptive clamping, repeatability ±0.02MM

Flexible clamping without affecting rotation speed.

No slip ring design

Longer life

No slip ring, rotation life of 10 million times

Strong anti-interference ability ensures high-precision movement

Strong overload resistance and improved environmental adaptability

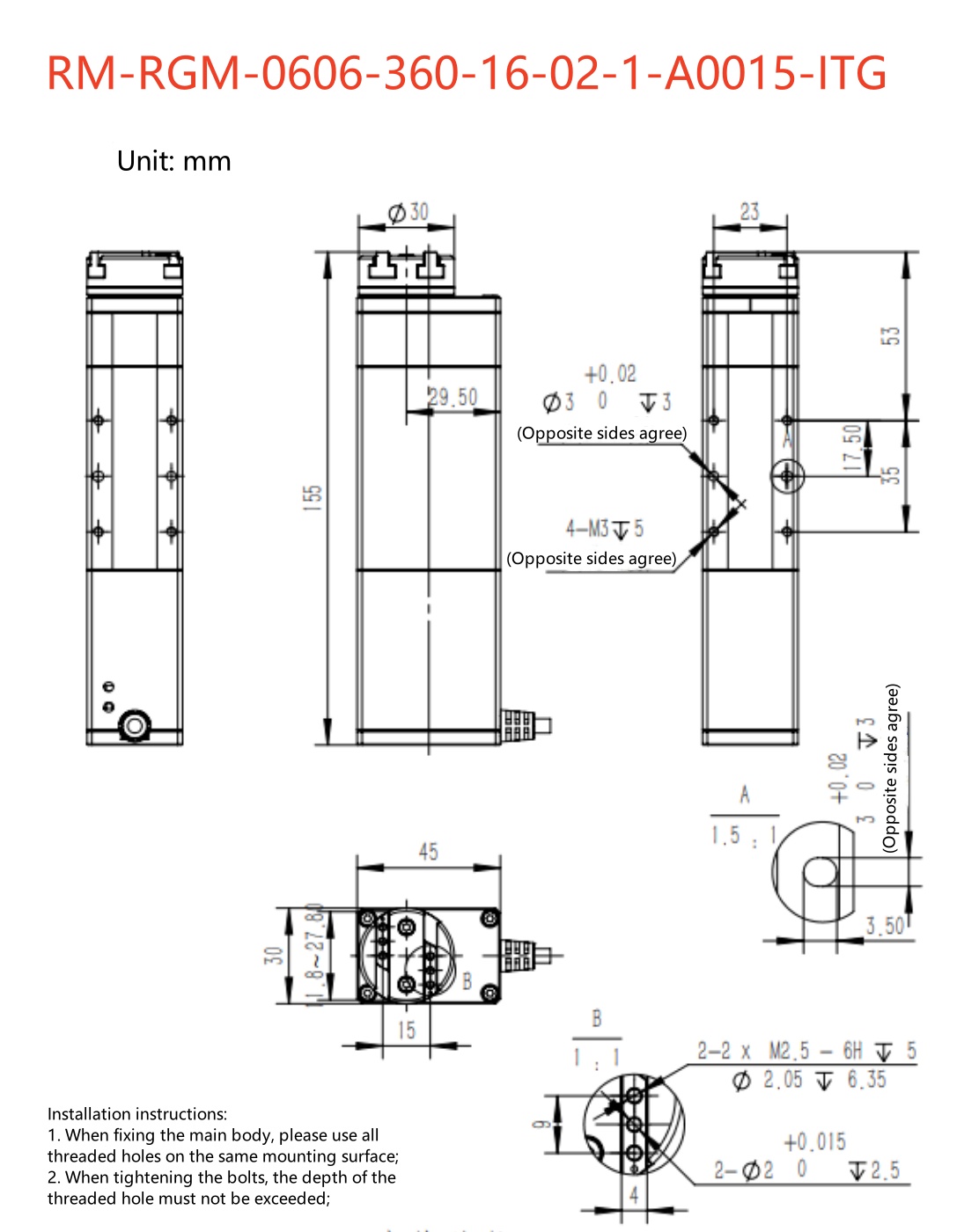

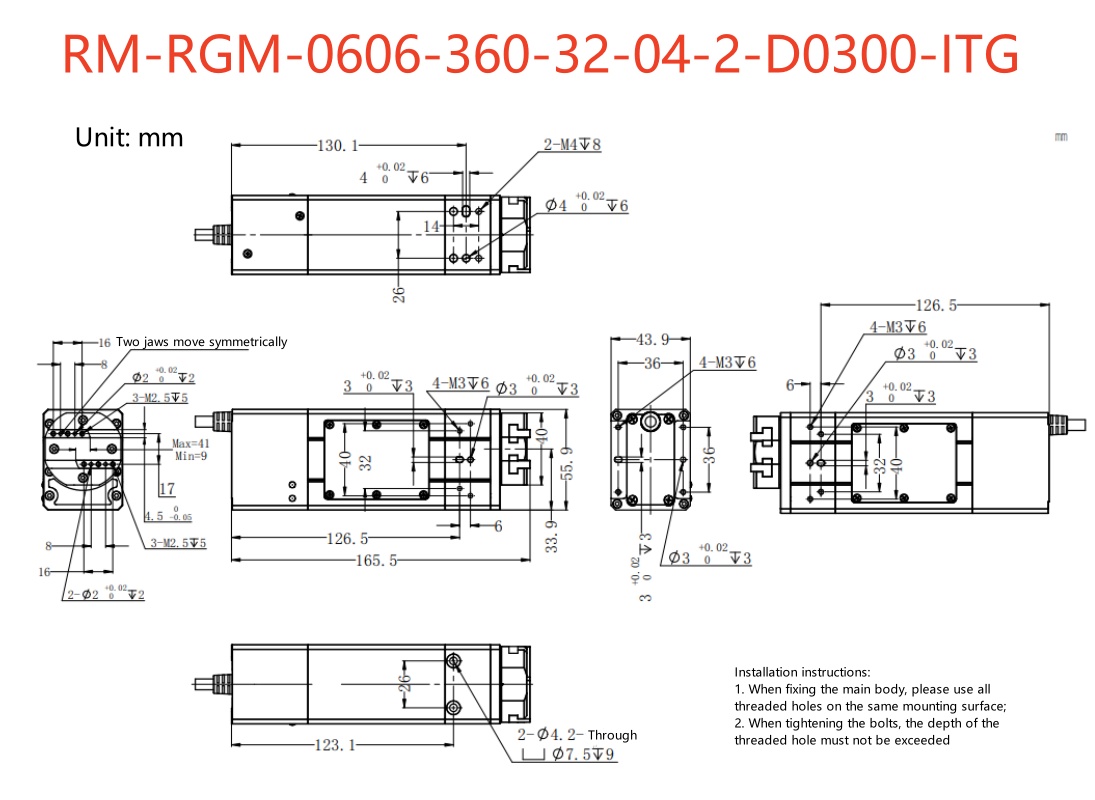

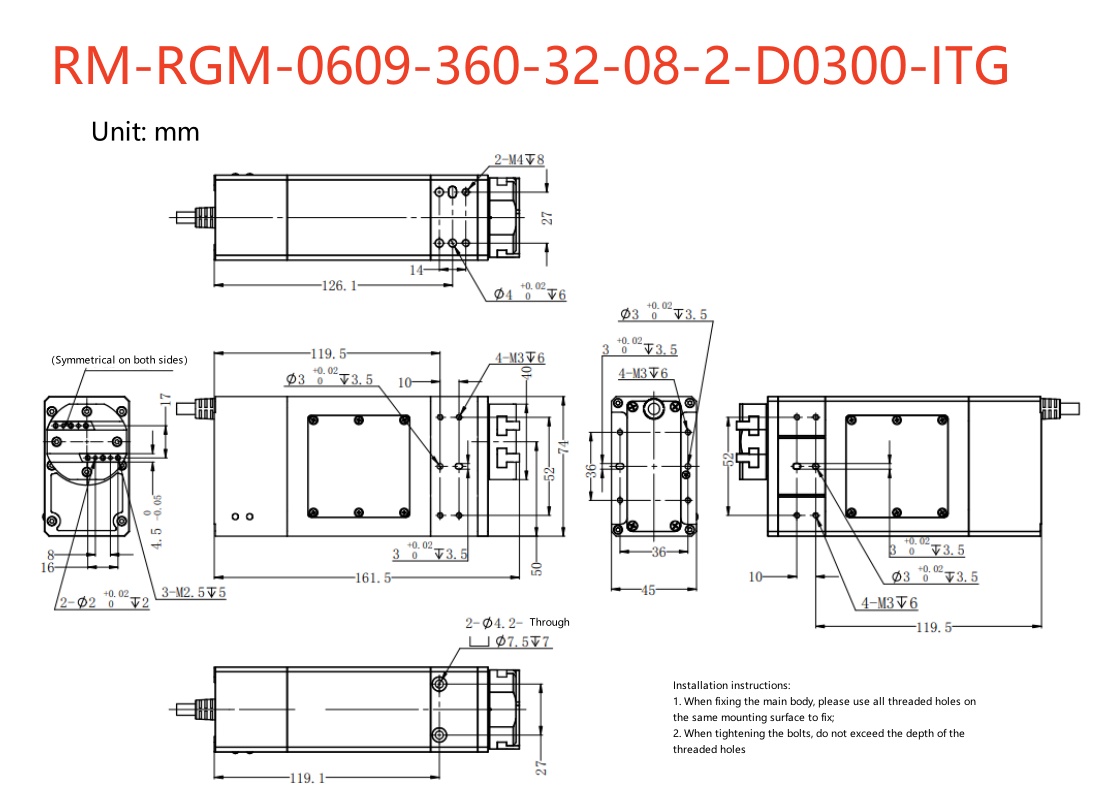

Size & Interface

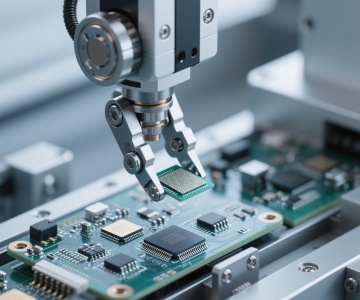

Application Cases

3C Electronic Manufacturing: On the production line of 3C electronic products, small precision parts such as chips and sensors need to be grasped and assembled with high precision and rotation. With its high precision, this gripper can accurately position and grasp, and its large torque and clamping force ensure stable handling. The adaptive clamping can handle parts of different sizes and shapes, and the slip ring-free structure ensures long-term stable operation, meeting the high precision and high reliability requirements of 3C electronic manufacturing.

Automotive parts assembly: In automobile production, many parts need to be accurately grasped and installed, such as engine parts and interior parts. The gripper's integrated rotation and clamping and discrete control characteristics allow it to be flexibly operated in a small space, and can accurately grasp and rotate parts of different weights and shapes. The large torque and clamping force ensure that heavier parts can be grasped stably, and the dual servo control ensures accurate and efficient movements, which helps the automation and intelligence of automotive parts assembly.

Machining loading and unloading: In the machining workshop, workpiece loading and unloading links need to frequently grasp workpieces of different specifications. The torque control of this gripper can adaptively clamp workpieces of different materials and sizes to avoid damage. The ultra-large torque and clamping force can handle workpieces of larger size and weight. The slip ring-free structure improves durability, reduces maintenance costs, and realizes efficient and stable automated operation during machining loading and unloading.