Product Description

Custom Aluminum Power Grips are precision CNC machined, using 6061/7075 alloy for high strength, rugged durability and stable mounting. Each component is tested for dimensional accuracy and performance under extreme conditions, making them ideal for heavy industrial, automotive and military applications that require efficiency, reliability and long-term performance. The modular design allows for easy customization and installation without compromising structural strength.

Product parameters

Custom Process

1. Inquiry

2. Negotiation

3. Payment Term

4. Machining Production

5. Inspection samples

6. Package

7.Transportation

8. After-sale support

Process Type

CNC Precision Machining

High-accuracy CNC milling and turning are used to shape the aluminum alloy (6061/7075) into complex grip structures, ensuring tight tolerances and consistent quality.

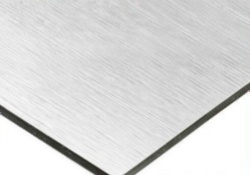

Surface Finishing & Treatment

Processes such as anodizing, bead blasting, or polishing are applied to enhance corrosion resistance, improve grip texture, and give a sleek, professional appearance.

Quality Inspection & Fit Testing

Each part undergoes dimensional checks, surface quality inspection, and functional testing to ensure secure fit, structural strength, and long-term performance under stress.

Material

Aluminum

Brass

Stainless Steel

Plastics

Quality Control

Processing capability

Additional processes