Product Description

Product parameters

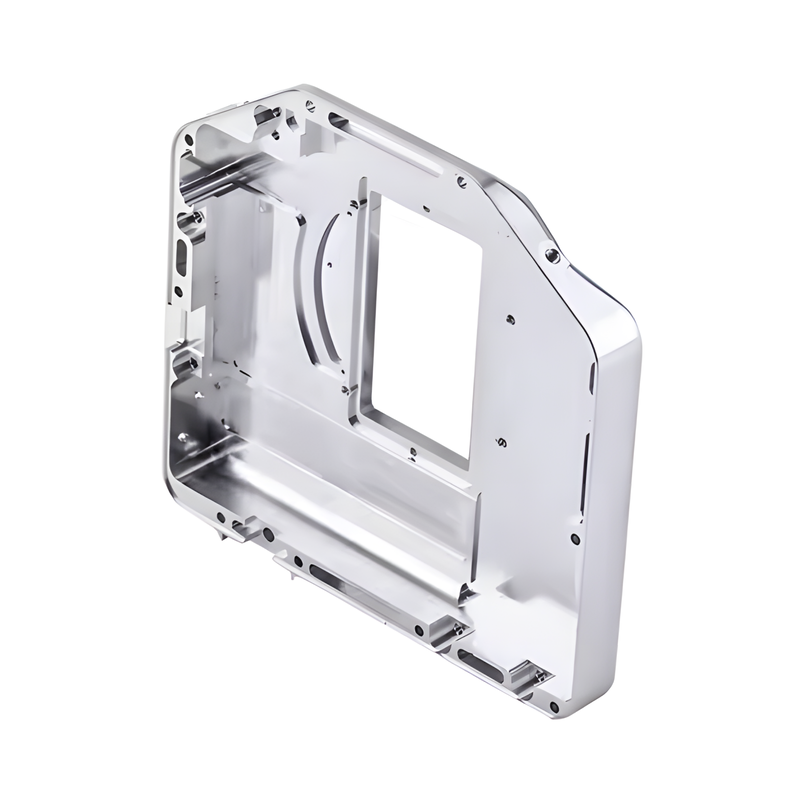

| Brand Name | Electronic Instruments Cnc Machined Aluminum Alloy Parts |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Material | Aluminum 6061/6063/5082/5083/7075 / etc. |

| Surface treatment | Customer's Request |

| Service | One Stop Service. Machining-assembly |

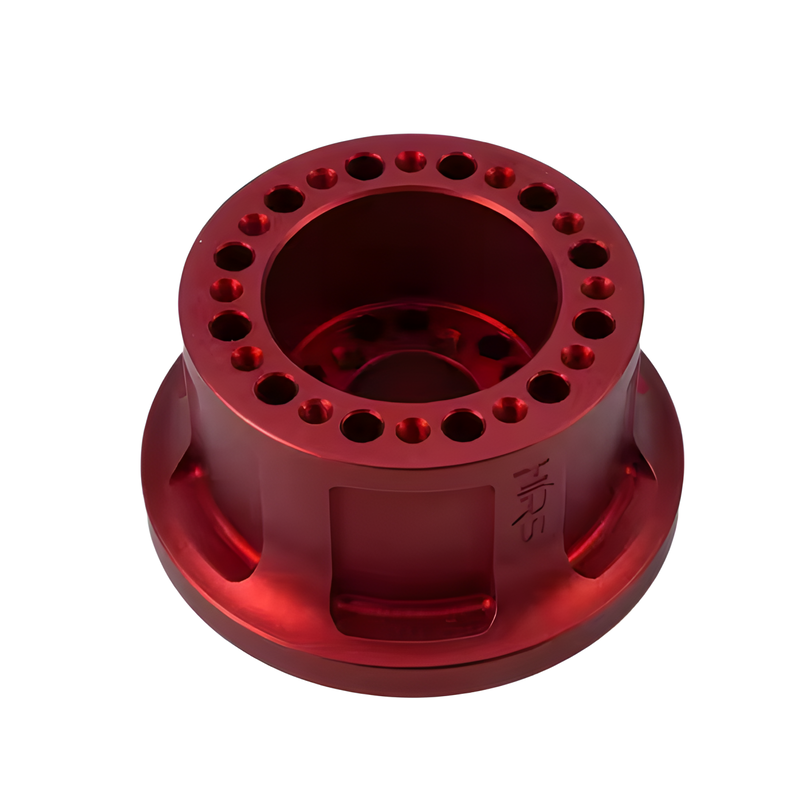

| Color | Customized Colors |

| Tolerance | 0.005mm |

| OEM/ODM | OEM ODM CNC Milling Turning Machining Service |

Custom Process

Upload your design

Design analysis

Start production

Receive your parts

Process Type

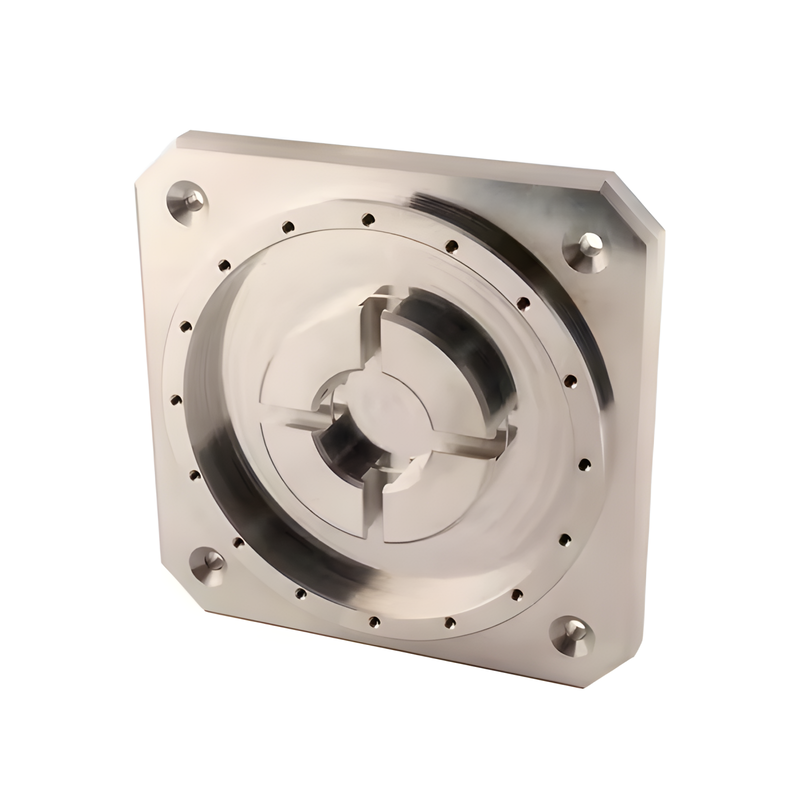

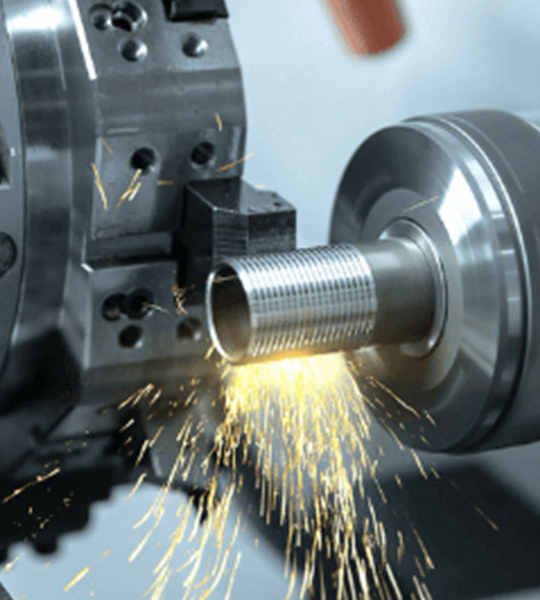

Milling & Drilling

CNC Machining

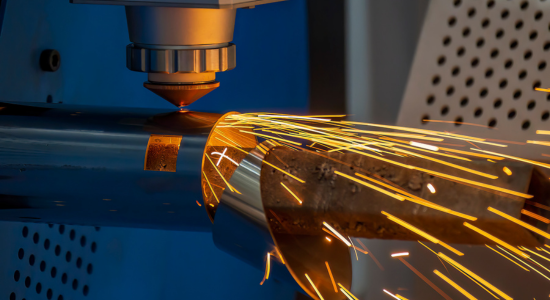

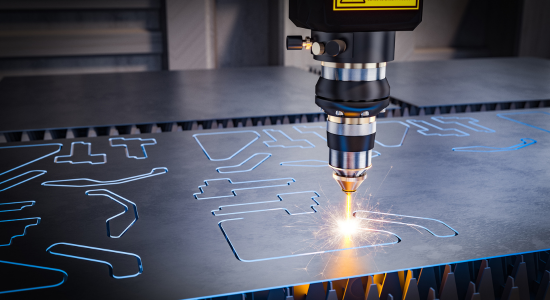

Laser Cutting

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

ISO 9001 certified quality management system ensuring consistent product quality.

100% inspection of all critical dimensions using precision tools like CMM and micrometers.

Rigorous in-process checks at various stages to maintain tight tolerances.

Material traceability and certification available upon request.

Surface finish, flatness, and thread dimensions checked to customer specifications.

FAI (First Article Inspection) and PPAP documentation support for quality assurance.

Non-destructive testing (NDT) available for added reliability.

Final inspection ensures all parts meet customer requirements before shipment.

Inspection reports provided with each batch or order.

Continuous improvement through customer feedback and regular audits.

Processing capability

Supports a variety of materials including aluminum 6061, 6063, 5082, 5083, and 7075.

Capabilities include broaching, etching, chemical machining, laser machining, and wire EDM.

Tolerances as tight as ±0.005 mm for high-precision components.

Flexible production from prototype to large-scale manufacturing.

Rapid prototyping to meet time-sensitive project requirements.

Surface treatments available upon request, including anodizing and plating.

Custom machining based on detailed customer drawings or CAD files.

High-quality finishing for applications requiring smooth surfaces and fine details.

Efficient production with optimized CAD/CAM integration for cost-effective machining.

Additional processes