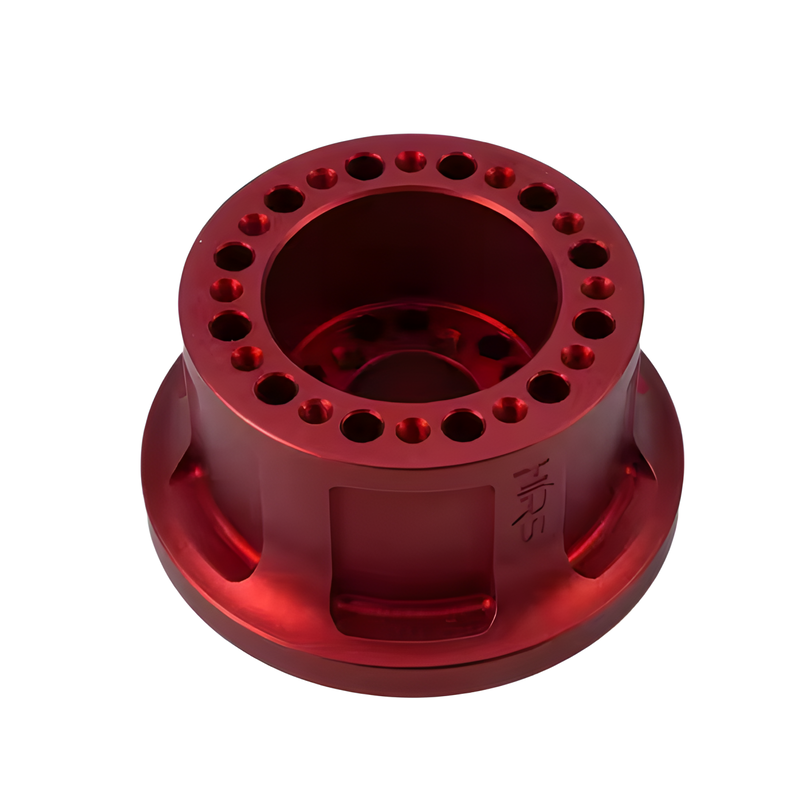

Product Description

Product parameters

| Brand Name | Forged Wheel Rim CNC Machining Parts |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys, Titanium / POM |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM |

| Capabilities | OEM Customized |

| Process | CNC Machining |

| Surface treatment | Anodizing /Nickel , Zinc , Chrome Plating |

| Application | Motorcycle parts |

| Customized | Accept |

| Drawings | .dwg .pdf .stp .igs |

Custom Process

Upload your design

Design analysis

Start production

Receive your parts

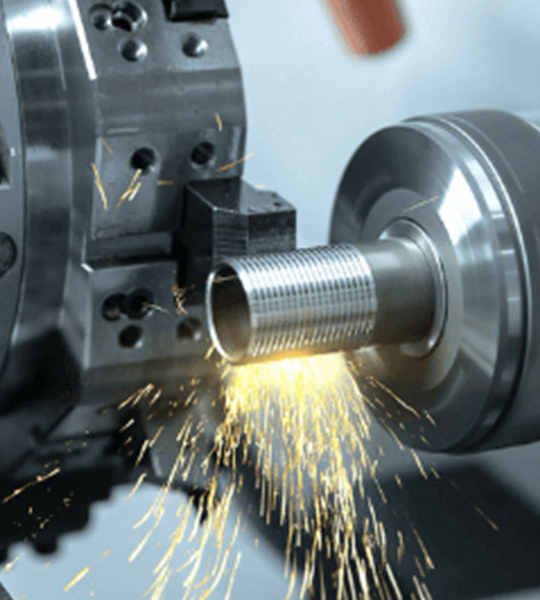

Process Type

Milling & Drilling

CNC Machining

Laser Cutting

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

Dimensional inspection using CMM ensures precise tolerances are met.

Surface roughness is checked to confirm smooth finishes (Ra standards).

Ultrasonic and dye penetrant testing detect internal and surface defects.

Balance testing ensures uniform weight distribution to avoid vibrations.

Material composition is verified with spectrometers for alloy consistency.

Documentation and traceability are maintained for each production batch.

Processing capability

CNC machining supports high-precision turning, milling, and drilling.

Handles complex geometries with multi-axis machining (up to 5-axis).

Supports tight tolerance levels up to ±0.01 mm.

Can process heat-treated forged aluminum or magnesium alloys.

Batch production scalability from prototypes to mass manufacturing.

Capable of automated tool changes and real-time process monitoring.