Product Description

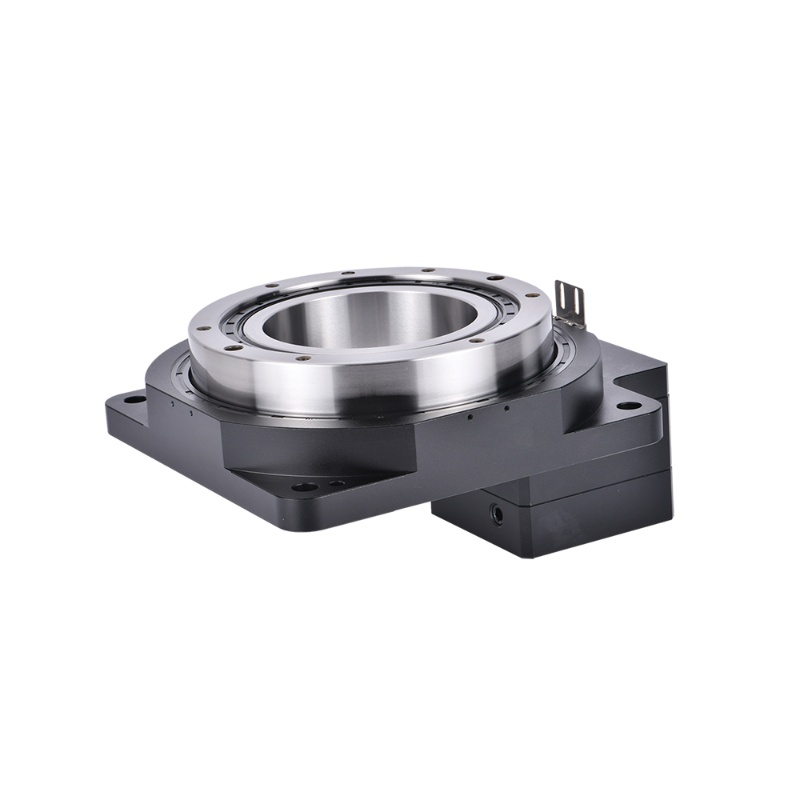

Our EH series robot integrated joint module is an innovative product designed for high-end intelligent equipment. With advanced integrated and hollow design concepts, it has achieved a double breakthrough in performance and appearance. The EH series products belong to the EH single encoder series, covering multiple models such as EH-14, EH-17, EH-20, EH-25, EH-32, etc., providing a torque output range of 11N·m~150N·m. With modular integrated design and hollow structure, the product achieves lightweight and weight reduction while ensuring high-performance output, thereby significantly improving the efficiency and accuracy of system integration.

The single encoder feedback system simplifies the hardware configuration while ensuring high-precision position control, greatly reducing the complexity of system integration. The combination of integrated design and hollow structure not only realizes internal wiring, improves the neatness and safety of the system, but also effectively reduces the time and manpower required by developers in joint integration, selection, installation and debugging, making robot development more efficient and easy.

Application

In terms of application scenarios, the EH series demonstrates excellent adaptability and is widely used in collaborative robotic arms, food processing equipment, medical equipment, CNC milling machines, shipbuilding industry, aerospace equipment and other fields. Whether it is demanding requirements for dynamic performance, load capacity or structural compactness, the EH series can provide ideal solutions to empower and accelerate customers' automation projects.

Collaborative Robot Arm

Food processing equipment

Medical Devices

CNC milling machine

Shipbuilding industry

Aerospace equipment

Choosing the EH series joint module means choosing efficient development, reliable performance and broad adaptability. We are committed to providing more intelligent and flexible motion control solutions for global developers, integrators and end users to help your robot products quickly achieve a leap from conception to implementation.

Product parameters

The following is a selection introduction of this series of products for your reference:

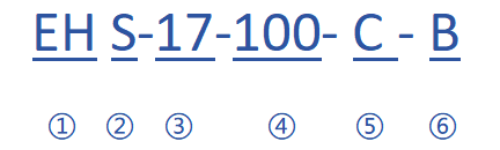

① EH Stands For The Series Name: Integrated Harmonic Module

② S:Single encoder D:Dual encoder

③ Harmonic Model e.g: 14/17/20/25/32 etc

④ Reduction ratio 1:100

⑤ Communication C:CANbus

⑥ N:Without Brake B:with Brake

For example:

Model EHS-20-100-C-N

illustrate EHS:Integrated hollow single encoder harmonic module 20:Harmonic model

100:Harmonic gear ratio1:100 C:CANbus Communication N:Without Brake

Parameters | EH-14 | EH-17 | EH-20 | EH-25 | EH-32 | |

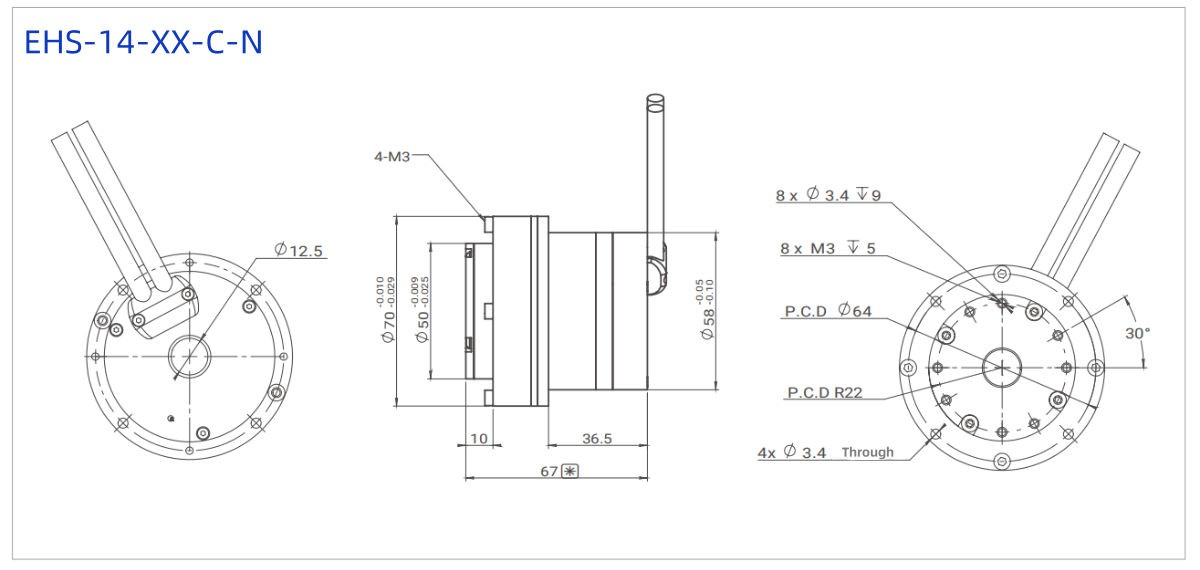

Outside diameter(mm) | 70 | 80 | 90 | 110 | 142 | |

Gear ratio | 100 | 100 | 100 | 100 | 100 | |

Input Voltage(V) | 48 | 48 | 48 | 48 | 48 | |

No Load Speed(RPM) | 30 | 30 | 30 | 30 | 20 | |

No Load Current(A) | 0.9 | 1.45 | 2.59 | 1.61 | 3.9 | |

Rated Speed(RPM) | 25 | 25 | 25 | 25 | 18 | |

Rated Torque(N.m) | 11 | 35 | 50 | 108 | 150 | |

Rated Power(W) | 100 | 180 | 250 | 400 | 700 | |

Rated Current(A) | 6.5 | 9 | 13 | 16 | 20 | |

Peak Torque(N.m) | 28 | 54 | 80 | 157 | 229 | |

Peak Current(A) | 16.25 | 13.86 | 20.8 | 23.2 | 33.44 | |

Back-EMF Constant(Vdc/Krpm) | 1.39 | 2.79 | 2.79 | 4.89 | 6.28 | |

Torque Constant(N.m/A) | 0.02 | 0.04 | 0.04 | 0.07 | 0.09 | |

Phase Resistance(Ω) | 0.9 | 0.77 | 0.38 | 0.23 | 0.08 | |

Phase Inductance(mH) | 0.4 | 0.38 | 0.33 | 0.3 | 0.13 | |

Pole Pair | 10 | 10 | 10 | 10 | 10 | |

Phase Connection | Y | Y | Y | Y | Y | |

Backlash(Arcsec) | < 20 | < 20 | < 20 | < 20 | < 20 | |

Encoder Type&Interface | ABS-17bit | ABS-17bit | ABS-17bit | ABS-17bit | ABS-17bit | |

Repeat Position Accuracy(Degree) | < 0.01 | < 0.01 | < 0.01 | < 0.01 | < 0.01 | |

Communication | CAN BUS | CAN BUS | CAN BUS | CAN BUS | CAN BUS | |

Weight(Kg) | N (without brake) | 0.71 | 1.1 | 1.45 | 2.3 | 4.3 |

B(with brake) | / | 1.25 | 1.6 | 2.82 | 4.7 | |

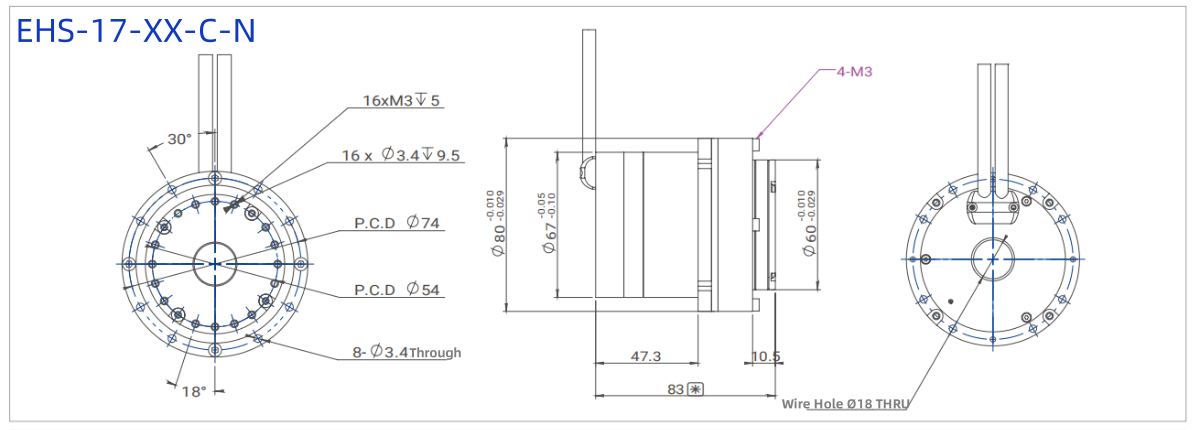

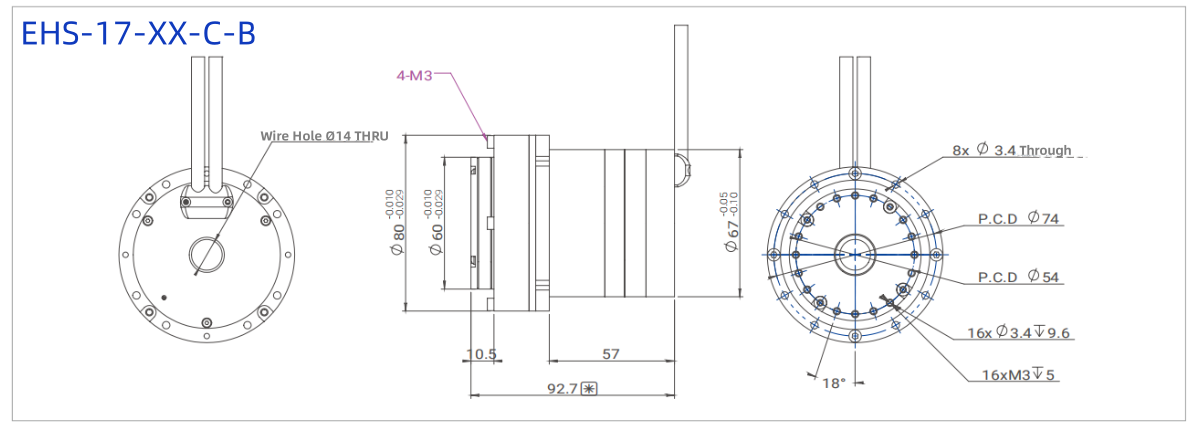

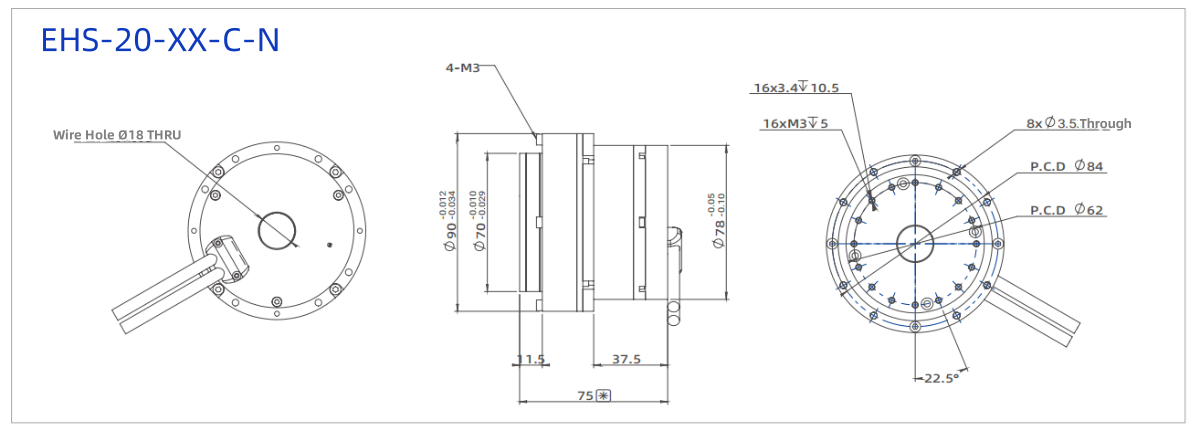

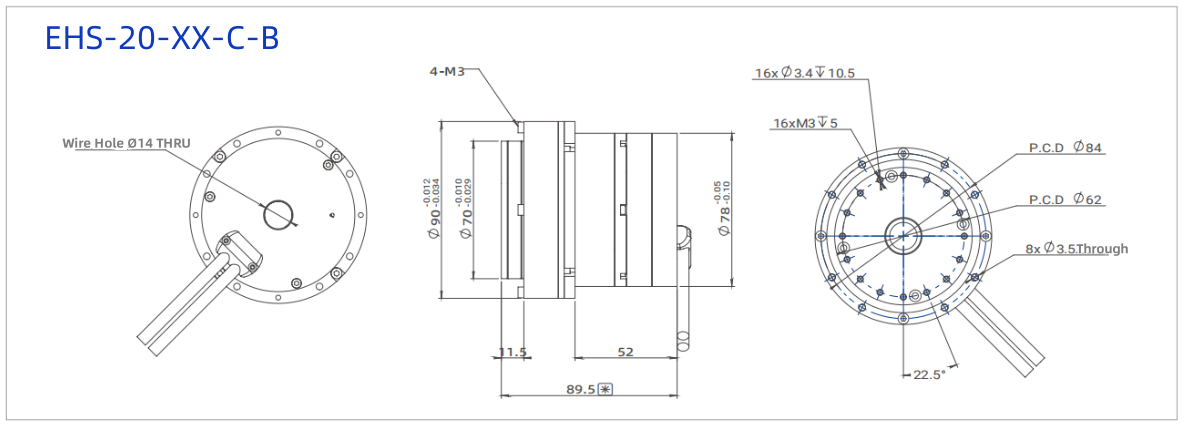

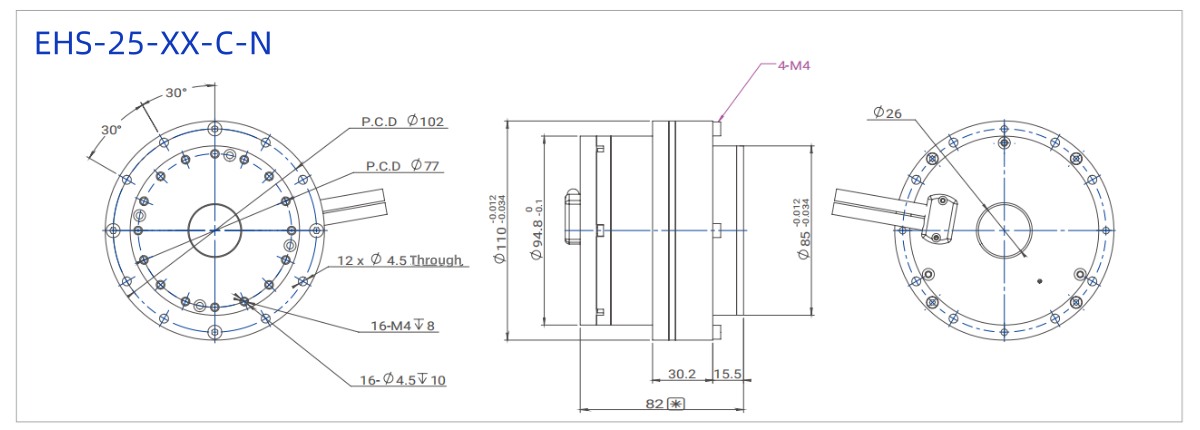

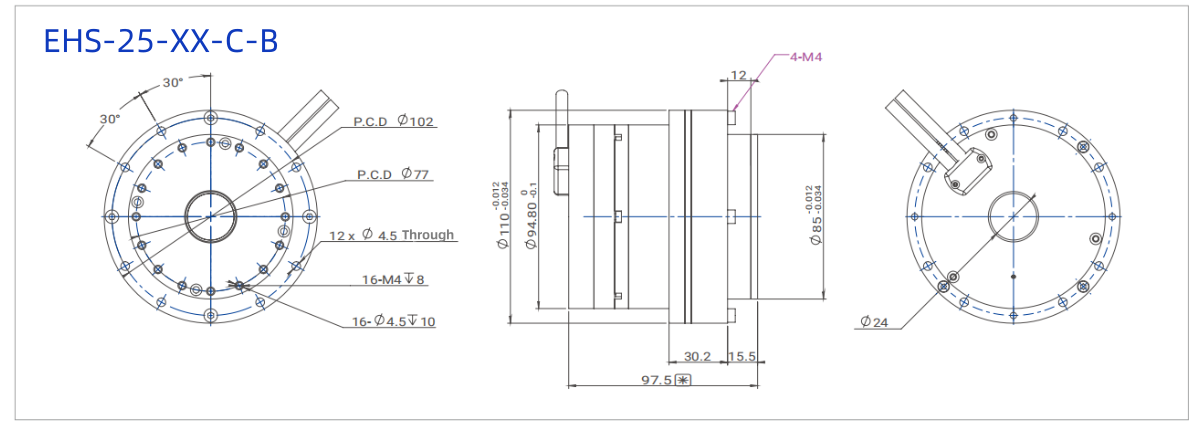

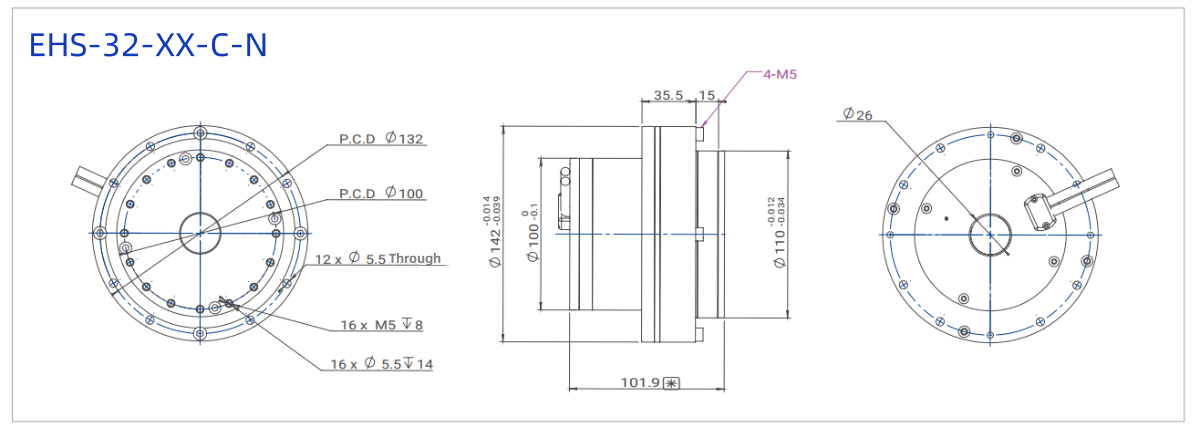

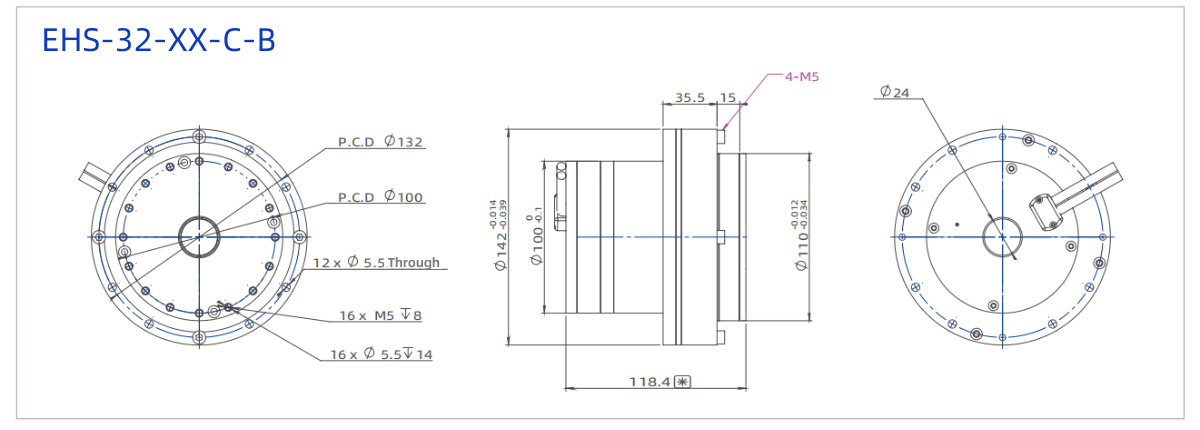

Length(mm) | N(without brake) | 67 | 83 | 75 | 82 | 101.9 |

B(with brake) | / | 92.7 | 89.5 | 97.5 | 118.4 | |

Insulation grade | F | F | F | F | F | |

* Rated torque test method: When the ambient temperature is 24 degrees Celsius (no other heat dissipation methods), the test is performed at the rated speed. The motor torque reaches temperature balance under the condition of a temperature rise of 60 degrees Celsius, and the long-term working point is the rated torque value of the motor.

* The standard motor can support both brake or without brake.

* The standard motor no IP protection. If need lP54 please contact salesman before order.

Note: IP56 protection means protection against harmful dust deposition and ability to withstand strong water spray, but does not support long-term immersion in water. If you need higher protection customization, please communicate and confirm in advance.

* The standard motor only support CAN BUS communication.

Dimensional Installation Drawing

FAQ

1. Does it support waterproof and dustproof? What is the protection level?

Yes, our joint modules can be customized with waterproof and dustproof functions according to customer needs. The standard version is not waterproof for indoor applications, and can be equipped with IP56 protection, which is suitable for certain outdoor or humid environments.

If you have higher protection requirements (such as IP67), you can contact us for customization.

2. Does it support customized reduction ratio?

Yes. We can provide customized solutions with different reduction ratios according to your application requirements.

The conventional reduction ratio range covers: 10:1 ~ 200:1, and the best combination can be matched according to load, speed, and torque requirements.

3. What is the difference between the single encoder and dual encoder versions?

The single encoder version monitors the rotation of the motor end and is suitable for general precision requirements; the dual encoder version monitors the motor end and the output end at the same time, which can effectively compensate for the backlash and elastic error, and is suitable for high-precision control and high safety requirements (such as collaborative robots, medical equipment).

4. What communication interfaces can the joint module support?

The standard version supports analog control (current/voltage command) or pulse command control;

According to the needs, it can be optionally equipped with support for industrial bus protocols such as CANopen, EtherCAT, Modbus-RTU, etc. (customization is required).

5. Does it support integrated drive and control? Can it be directly connected to the controller?

We provide optional integrated drive and control joint modules with built-in motor drivers and position servo controllers.

Users can directly control through the bus or pulse interface without external independent drivers, simplifying wiring and system integration.

6. Is there a standard 3D model file available for download?

Yes. We provide 3D model files in STEP format for all models, which is convenient for customers to quickly integrate mechanical design.

If you need to obtain it, please contact our sales staff to obtain the download link or data package.

7. What is the operating temperature range?

The standard operating temperature range is: -10°C ~ +50°C.

If you need to resist low or high temperature application environments (such as cold storage, hot working environment), you can customize special temperature control solutions.

8. Can the joint module be designed to be hollow? Can it be wired?

Some models are hollow shaft designs, and the center aperture can be used for wiring, air pipes, water pipes, etc., which is convenient for realizing the functional layout of complex end effectors.

For specific center aperture dimensions, please refer to the model selection table or consult customer service.

9. How long is the standard delivery period and customized delivery period?

Standard model delivery period: usually 7-14 working days.

The delivery period for customized requirements (such as IP56 waterproof, reduction ratio customization, communication protocol customization, etc.) depends on specific requirements, generally 5-10 weeks.

10. How long is the warranty period? How about after-sales service?

All joint module products have a 12-month warranty period (under normal use).

We provide remote technical support, fault diagnosis guidance, and fast spare parts supply services. Paid repair and maintenance services are also available outside the warranty period.