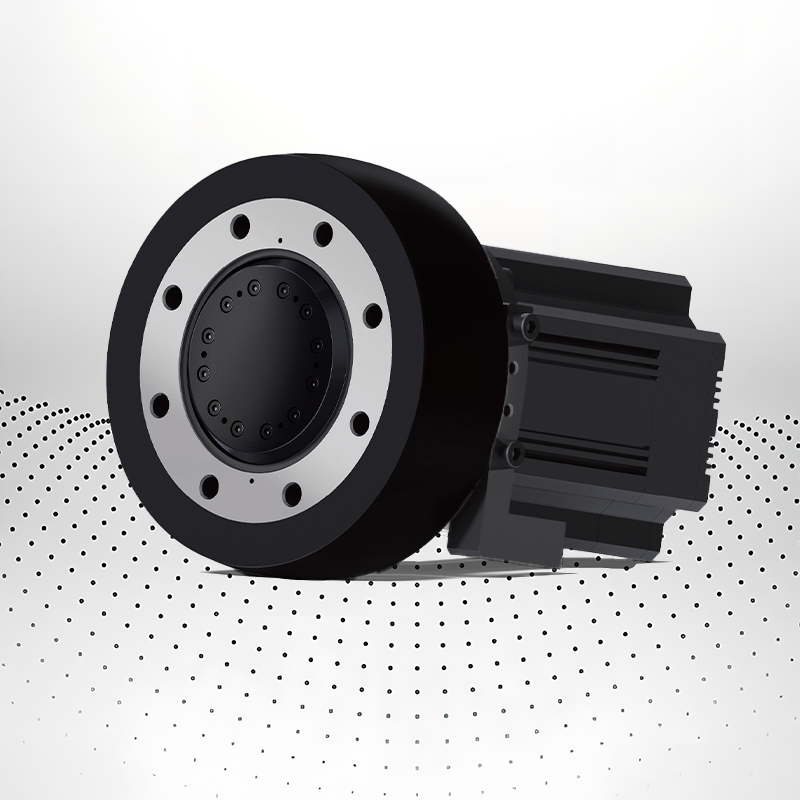

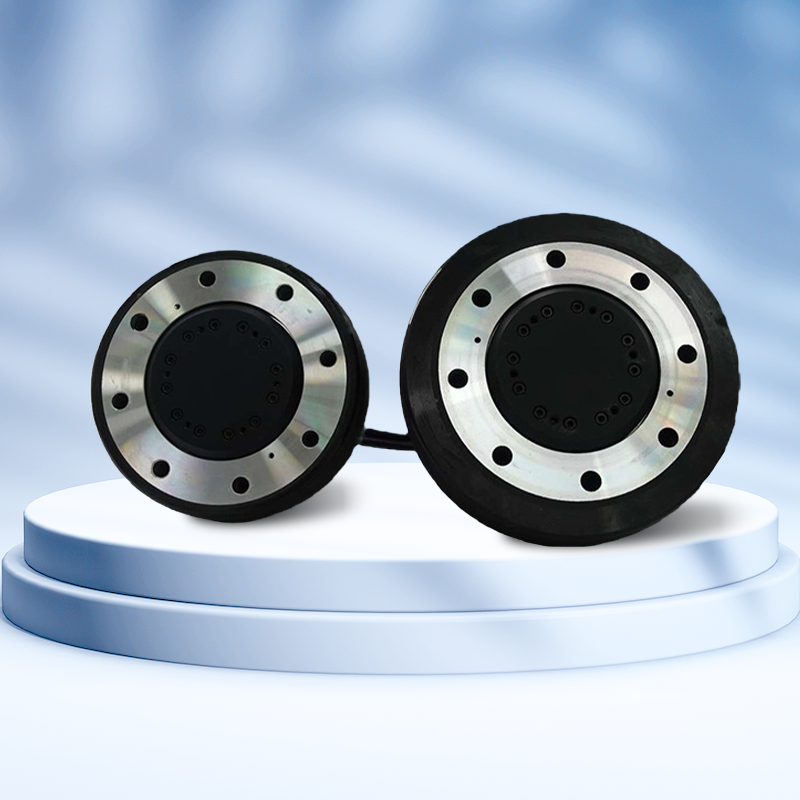

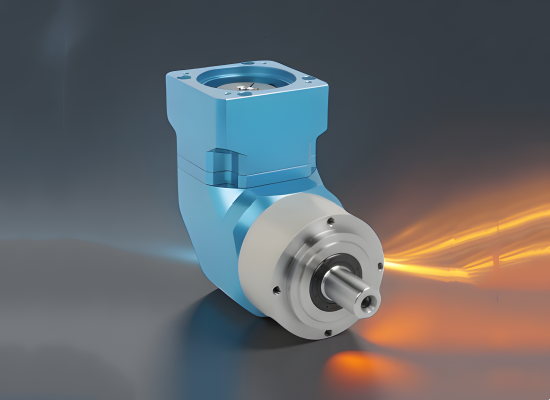

Product Description

TAER series precision planetary reducer is the best choice for industrial transmission. It adopts helical gear design, low noise and quiet operation. Large size, large span double support bearing output shaft, strong rigidity and high torque. Excellent efficiency performance, single stage over 93%, double stage over 90%, significant energy saving. It has maintenance-free characteristics, low grease wear, lifelong lubrication. IP65 protection, effective anti-leakage. One-piece corner housing design, saving space and ensuring precision. Suitable for all kinds of servo motors, widely used.

Functional Features

Low Noise: The use of helical gear design, to achieve a smooth, quiet operation of the reducer.

High Rigidity, High Torque: The output shaft used large size, large span double support bearing design,which improves the rigidity and torque of the reducer.

High Efficiency: 1-Stage up to 93% or more, 2-Stage up to 90% or more.

Maintenance-Free: Low grease wear, can be lifetime lubrication.

Sealing Effect Is Good: Lubricating grease with high viscosity, not easy to separate the characteristics, ip65 protection class to ensure that no grease leakage.

Space Saving: Right angle housing with integrated design, both to ensure the accuracy of the reducer operation can save space.

Wide Applicability: Applicable to any type of servo motor.

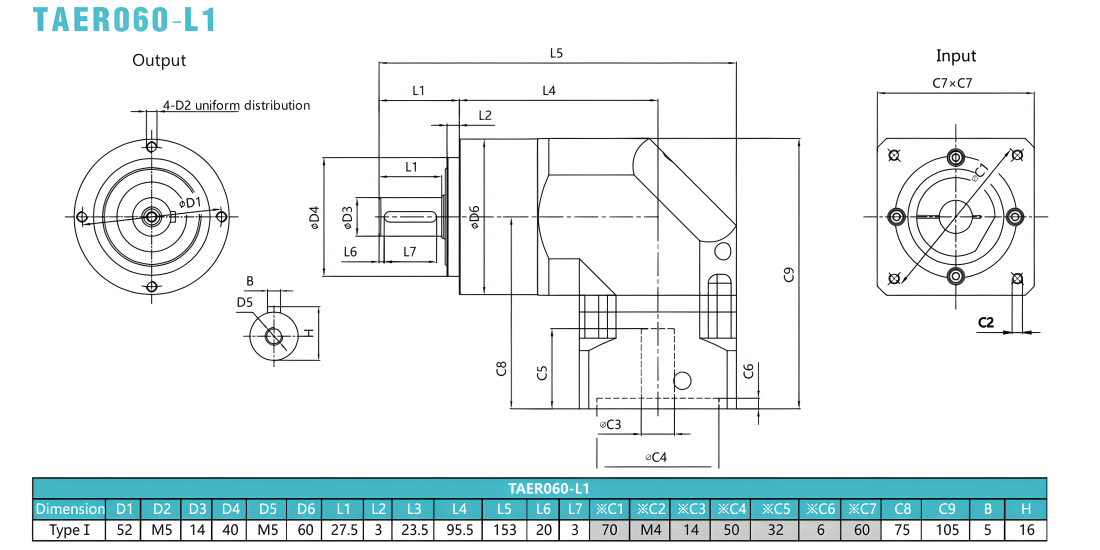

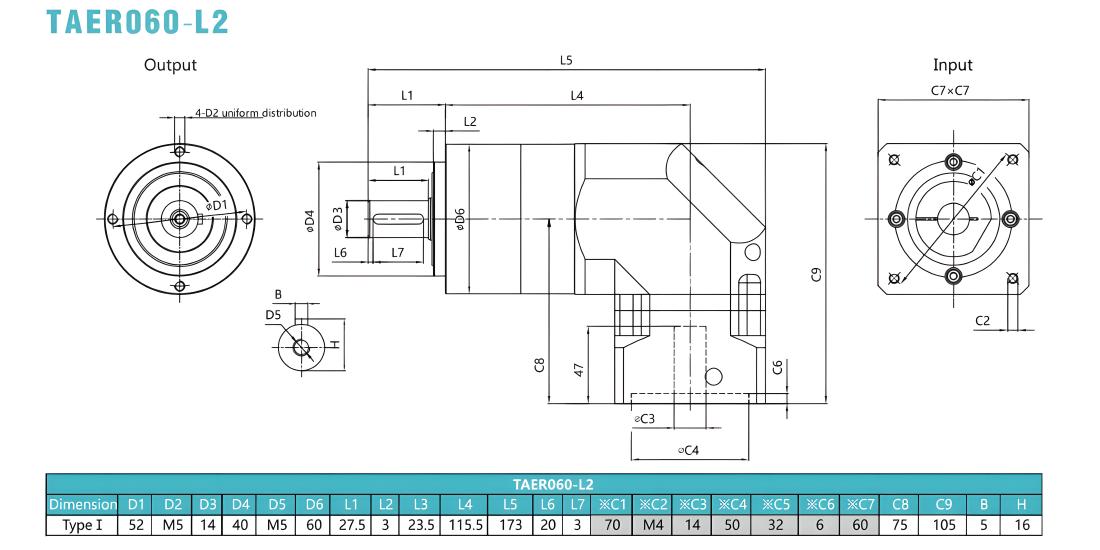

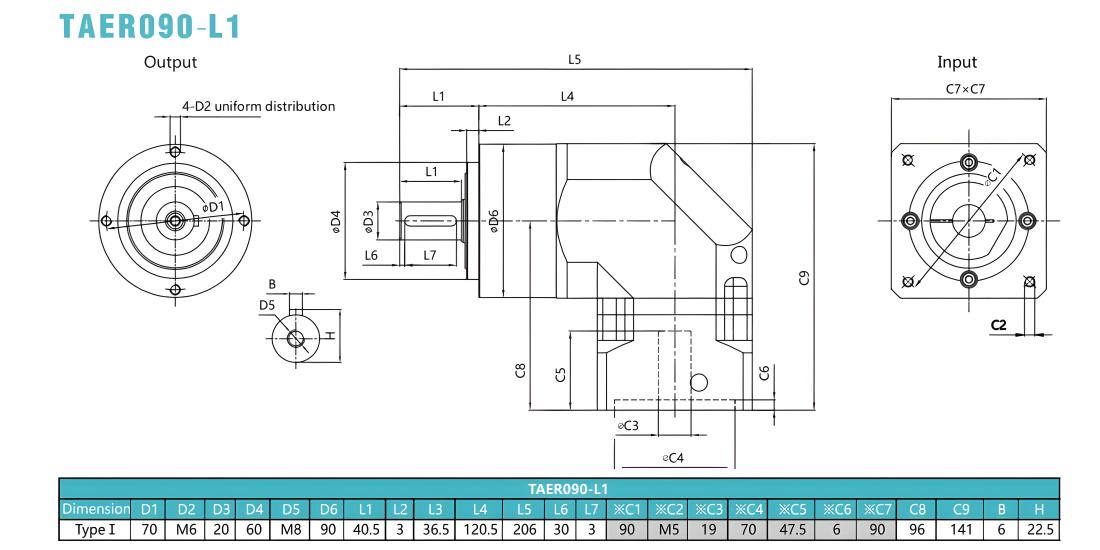

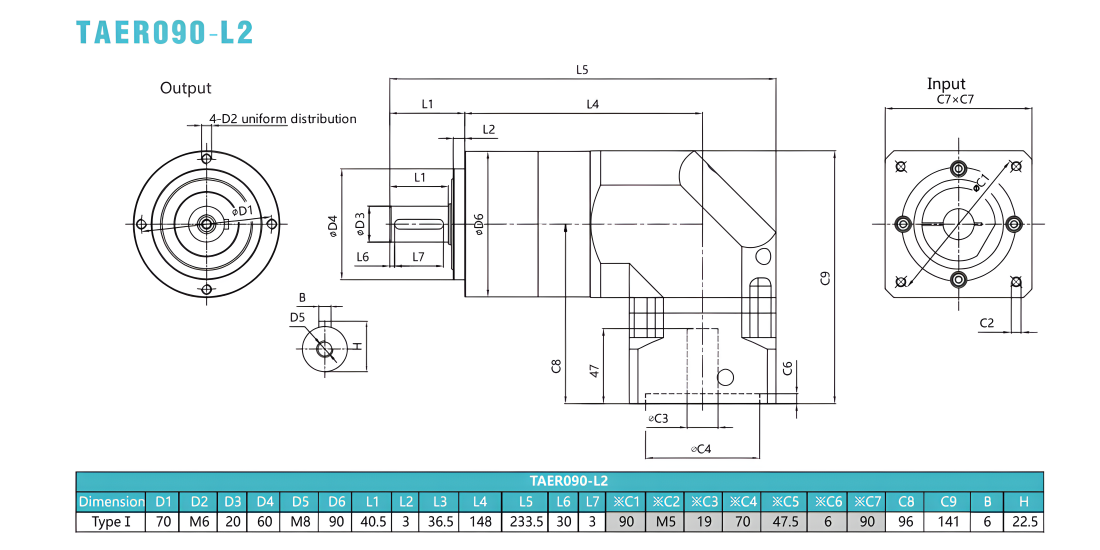

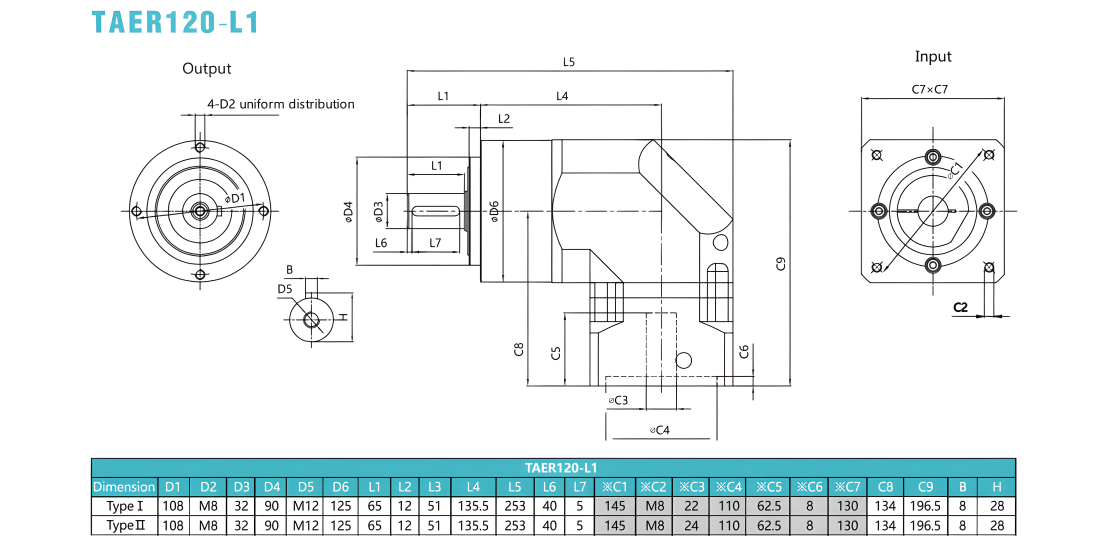

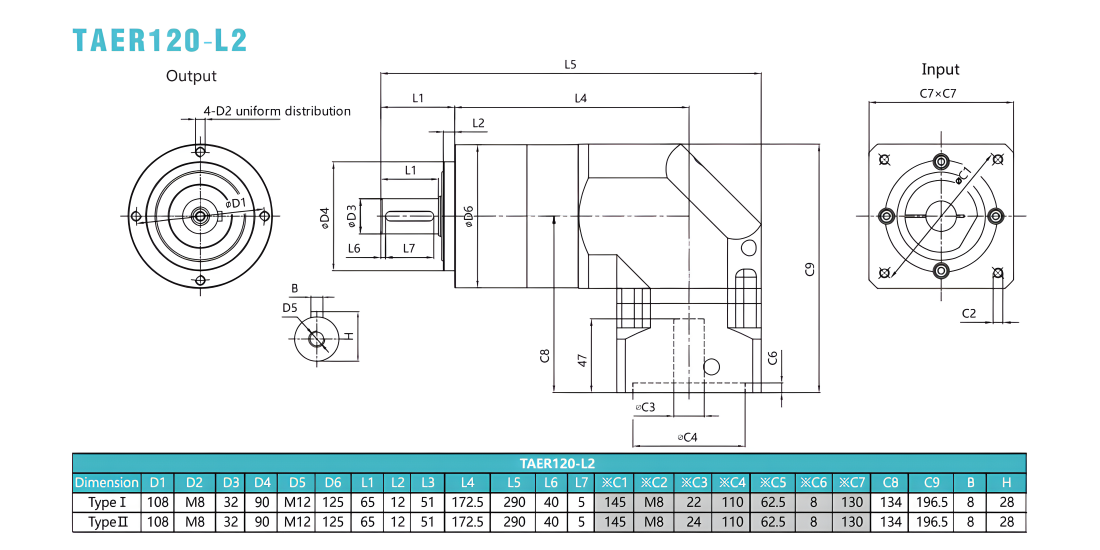

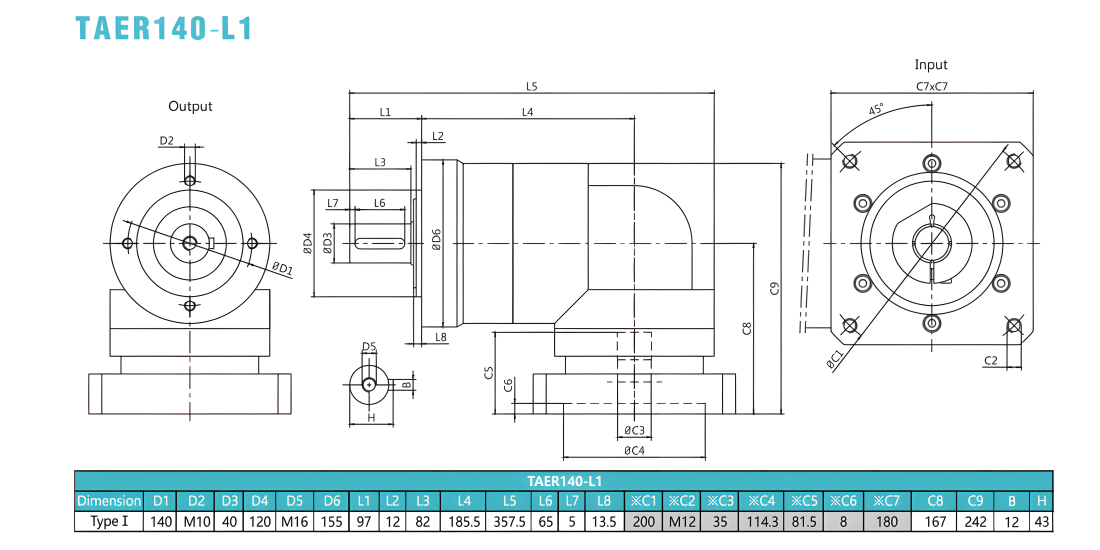

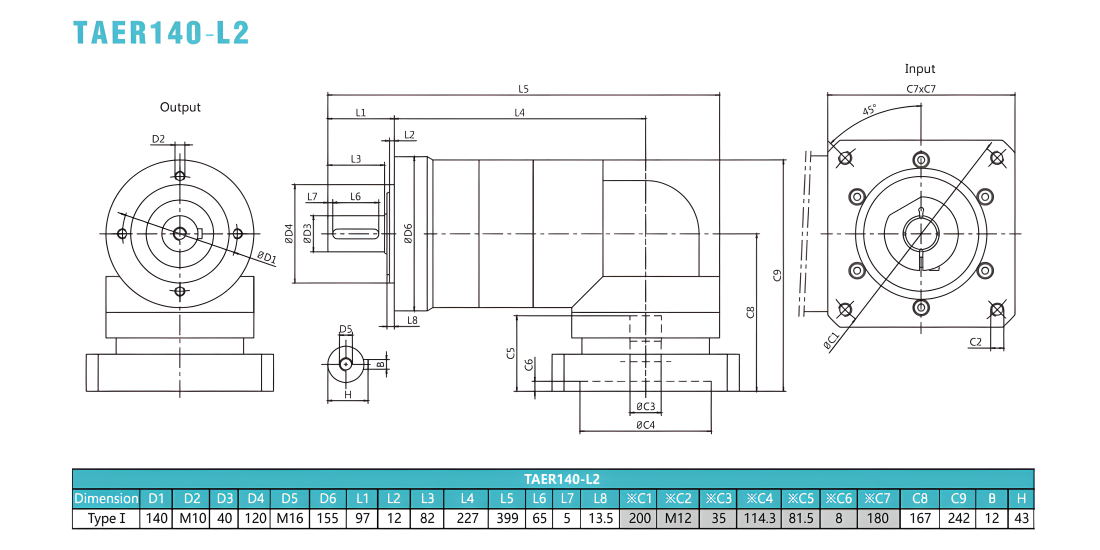

Dimensional drawing

※Dimension can be customized according to the motor,if necessary,please contact us!

Product parameters

TAER60 | |||||||||||||||

Parameter name | Unit | Value | |||||||||||||

Ratio | - | 3 | 4 | 5 | 7 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 70 | 100 |

Nominal Output Torque T2N | Nm | 35 | 40 | 45 | 40 | 30 | 35 | 45 | 45 | 40 | 40 | 40 | 45 | 40 | 30 |

Emergency Stop Torque T2NOT | Nm | 2.5 times of Nominal Output Torque | |||||||||||||

Nominal Input Speed n1N | rpm | 5000 | |||||||||||||

Max. Input Speed n1B | rpm | 10000 | |||||||||||||

Torsional Rigidity | Nm/arcmin | 5 | |||||||||||||

Max. Bending moment M2XB | Nm | 1300 | |||||||||||||

Max. Axial Load F2aB | N | 550 | |||||||||||||

Service Life | hr | 20000 (continuous operation life is halved①) | |||||||||||||

Noise | dB | ≤70(Input speed = 3000rpm, no load, distance 1M②) | |||||||||||||

Operating Temp | ℃ | -10 ~+90 | |||||||||||||

Degree of Reducer Protection | - | IP65 | |||||||||||||

Lubrication | - | Synthetic lubrication oils | |||||||||||||

Mass Moments of Inertia J1 | kg-cm² | 0.16 | 0.14 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 |

Standard Backlash P2 | arcmin | ≤8 | ≤10 | ||||||||||||

Efficiency η | % | ≥93% | ≥90% | ||||||||||||

① Half - life under continuous operation mode. | |||||||||||||||

② Reducer under no - load mode,input speed is 3000,the value which Noise Measurement machine get at one meter away position. | |||||||||||||||

TAER90 | |||||||||||||||

Parameter name | Unit | Value | |||||||||||||

Ratio | - | 3 | 4 | 5 | 7 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 70 | 100 |

Nominal Output Torque T2N | Nm | 100 | 110 | 125 | 110 | 80 | 100 | 110 | 125 | 110 | 125 | 110 | 125 | 110 | 80 |

Emergency Stop Torque T2NOT | Nm | 2.5 times of Nominal Output Torque | |||||||||||||

Nominal Input Speed n1N | rpm | 4000 | |||||||||||||

Max. Input Speed n1B | rpm | 8000 | |||||||||||||

Torsional Rigidity | Nm/arcmin | 11 | |||||||||||||

Max. Bending moment M2XB | Nm | 2800 | |||||||||||||

Max. Axial Load F2aB | N | 1000 | |||||||||||||

Service Life | hr | 20000 (continuous operation life is halved①) | |||||||||||||

Noise | dB | ≤70(Input speed = 3000rpm, no load, distance 1M②) | |||||||||||||

Operating Temp | ℃ | -10 ~+90 | |||||||||||||

Degree of Reducer Protection | - | IP65 | |||||||||||||

Lubrication | - | Synthetic lubrication oils | |||||||||||||

Mass Moments of Inertia J1 | kg-cm² | 0.61 | 0.48 | 0.47 | 0.45 | 0.44 | 0.47 | 0.47 | 0.47 | 0.44 | 0.45 | 0.44 | 0.44 | 0.13 | 0.13 |

Standard Backlash P2 | arcmin | ≤8 | ≤10 | ||||||||||||

Efficiency η | % | ≥93% | ≥90% | ||||||||||||

① Half - life under continuous operation mode. | |||||||||||||||

② Reducer under no - load mode,input speed is 3000,the value which Noise Measurement machine get at one meter away position. | |||||||||||||||

TAER120 | |||||||||||||||

Parameter name | Unit | Value | |||||||||||||

Ratio | - | 3 | 4 | 5 | 7 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 70 | 100 |

Nominal Output Torque T2N | Nm | 170 | 220 | 250 | 200 | 180 | 170 | 220 | 250 | 220 | 200 | 220 | 250 | 200 | 180 |

Emergency Stop Torque T2NOT | Nm | 2.5 times of Nominal Output Torque | |||||||||||||

Nominal Input Speed n1N | rpm | 4000 | |||||||||||||

Max. Input Speed n1B | rpm | 8000 | |||||||||||||

Torsional Rigidity | Nm/arcmin | 18 | |||||||||||||

Max. Bending moment M2XB | Nm | 5200 | |||||||||||||

Max. Axial Load F2aB | N | 2300 | |||||||||||||

Service Life | hr | 20000 (continuous operation life is halved①) | |||||||||||||

Noise | dB | ≤72(Input speed = 3000rpm, no load, distance 1M②) | |||||||||||||

Operating Temp | ℃ | -10 ~+90 | |||||||||||||

Degree of Reducer Protection | - | IP65 | |||||||||||||

Lubrication | - | Synthetic lubrication oils | |||||||||||||

Mass Moments of Inertia J1 | kg-cm² | 3.25 | 2.74 | 2.71 | 2.62 | 2.57 | 2.71 | 2.71 | 2.71 | 2.57 | 2.62 | 2.57 | 2.57 | 0.44 | 0.44 |

Standard Backlash P2 | arcmin | ≤8 | ≤10 | ||||||||||||

Efficiency η | % | ≥93% | ≥90% | ||||||||||||

① Half - life under continuous operation mode. | |||||||||||||||

② Reducer under no - load mode,input speed is 3000,the value which Noise Measurement machine get at one meter away position. | |||||||||||||||

TAER140 | |||||||||||||||

Parameter name | Unit | Value | |||||||||||||

Ratio | - | 3 | 4 | 5 | 7 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 70 | 100 |

Nominal Output Torque T2N | Nm | 342 | 542 | 650 | 550 | 450 | 342 | 542 | 650 | 600 | 550 | 542 | 650 | 550 | 450 |

Emergency Stop Torque T2NOT | Nm | 2.5 times of Nominal Output Torque | |||||||||||||

Nominal Input Speed n1N | rpm | 3000 | |||||||||||||

Max. Input Speed n1B | rpm | 6000 | |||||||||||||

Torsional Rigidity | Nm/arcmin | 50 | |||||||||||||

Max. Bending moment M2XB | Nm | 9400 | |||||||||||||

Max. Axial Load F2aB | N | 4700 | |||||||||||||

Service Life | hr | 20000 (continuous operation life is halved①) | |||||||||||||

Noise | dB | ≤75(Input speed = 3000rpm, no load, distance 1M②) | |||||||||||||

Operating Temp | ℃ | -10 ~+90 | |||||||||||||

Degree of Reducer Protection | - | IP65 | |||||||||||||

Lubrication | - | Synthetic lubrication oils | |||||||||||||

Mass Moments of Inertia J1 | kg-cm² | 9.21 | 7.54 | 7.42 | 7.14 | 7.03 | 7.42 | 7.42 | 7.42 | 7.03 | 7.14 | 7.03 | 7.03 | 2.57 | 2.57 |

Standard Backlash P2 | arcmin | ≤8 | ≤10 | ||||||||||||

Efficiency η | % | ≥93% | ≥90% | ||||||||||||

① Half - life under continuous operation mode. | |||||||||||||||

② Reducer under no - load mode,input speed is 3000,the value which Noise Measurement machine get at one meter away position. | |||||||||||||||

Precautions For Use

1.Select the reasonable reducer, damage of reducer may happen if choosen a reducer beyond the right power.

2.During the set up of reducer, please do not use the hammer hitting the reducer body, in case of impacting the accuracy during running.

3.Under the running status of reducer, do not put the hands or other objects on the rotary shaft, in case of injury.

4.Any uncommon sound /nosie or uncommon vibration, please stop the reducer running and contact us, we will provide the best solution.

5.Do not disassemble the reducer, no guarantee on performance after reassemblying.

6.Start the reducer step by step, do not lift the loader to the upper limit.

7.To extend the life of reducer, please do not put the reducer in bad environment.

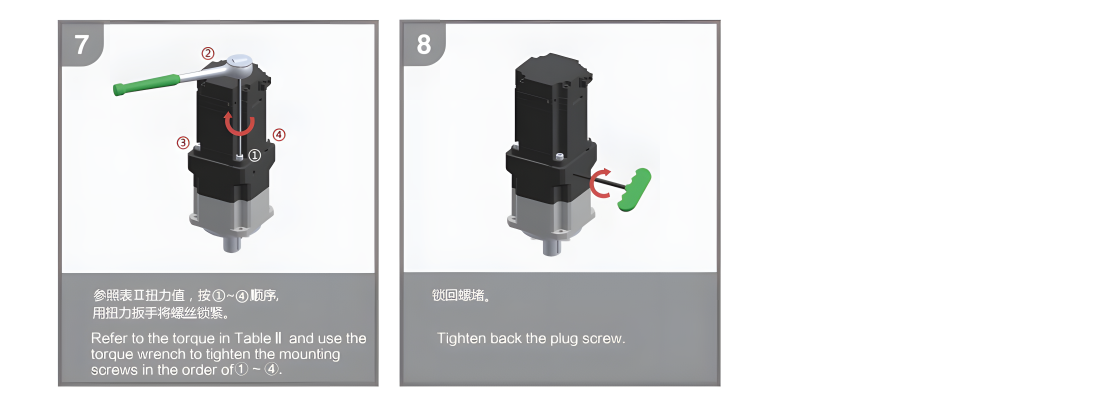

Mounting lnstruction

Table I Motor Lock Sleeve Screw Tightening Torque

|

|

|

| |

mm | Nm | In-lbs | ||

040-Series | M4 | 3 | 4.9 | 44 |

060 Series | M5 | 4 | 9.8 | 87 |

090 Series | M6 | 5 | 17 | 151 |

120/140 Series | M8 | 6 | 41 | 364 |

180 Series | M10 | 8 | 80 | 709 |

220 Series | M12 | 10 | 139 | 1232 |

TableII Motor Mounting Screw Tightening Torque

|

|

| |

mm | Nm | In-lbs | |

M3 | 2.5 | 2.1 | 19 |

M4 | 3 | 4.9 | 44 |

M5 | 4 | 9.8 | 87 |

M6 | 5 | 17 | 151 |

M8 | 6 | 41 | 364 |

M10 | 8 | 80 | 709 |

M12 | 10 | 139 | 1232 |

M16 | 14 | 343 | 3038 |

Application

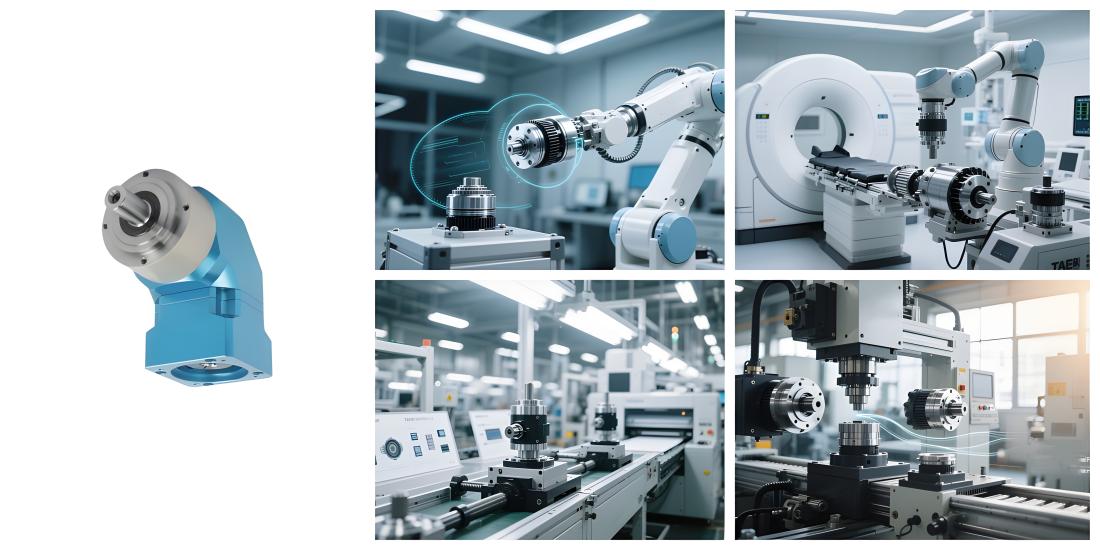

TAER series precision planetary reducers are widely used. In industrial automation, they can precisely control the speed and position of CNC machine tools and automated production lines to improve production efficiency and precision; in the field of robotics, they can be used in joints to achieve flexible and precise movement to meet complex operational requirements; in medical equipment, they can help CT scanners, surgical robots, etc. to operate stably and ensure the accuracy of medical operations; in the electronics manufacturing industry, they can provide precision transmission for high-precision printers, etc. to ensure the production of high-quality electronic products.

Quality Assurance

We always regard product quality as our core competitiveness, and strictly adhere to the industry's high standards throughout the production of planetary reducers. When raw materials enter the factory, we conduct composition analysis and mechanical property testing on key materials such as steel and bearings to ensure quality at the source; high-precision CNC equipment is used in the production process, and quality control points are set in each process to strictly control parameters such as gear accuracy and housing tolerance; before the finished product leaves the factory, it passes multi-dimensional performance tests such as no-load, load, and noise to ensure that indicators such as transmission efficiency and sealing meet the standards. The full-process quality inspection system ensures the stable performance of each planetary reducer.

After-sale guarantee

If a product fails, our after-sales team will respond immediately and quickly arrange for professional technicians to communicate with you to understand the details of the failure. We will provide you with remote technical guidance based on the specific situation to help you solve the problem. At the same time, we also provide you with regular return visits to understand the use of the product and collect your opinions and suggestions in order to continuously optimize our products and services. When the product is upgraded, we will also notify you in a timely manner and provide you with corresponding technical support and solutions to keep your equipment in good performance.