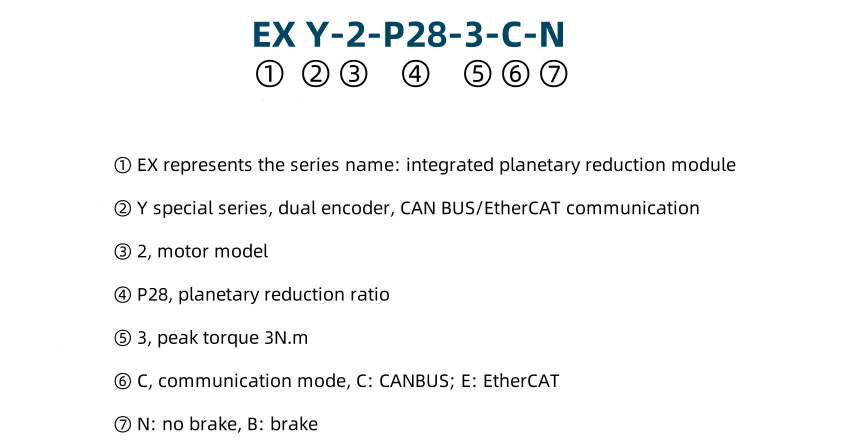

Product Description

This series is the latest model, with multiple optional models: EXY 2-7, EXY 4-10, EXY 4-36, EXY 6-60, EXY 8-120, EXY 12-320, EXY 15-450; rated torque range: 2.5N.m~145N.m. Hollow design, dual encoders, high speed; high torque density. Suitable for robotic arms/humanoid robots/exoskeleton robots/quadruped robots, etc.

1. The standard motor does not support brakes, which can be customized if needed.

2. The standard motor does not support waterproofing, which can be customized to IP54 if needed.

3. The standard motor supports CAN BUS and EARTHE CAT.

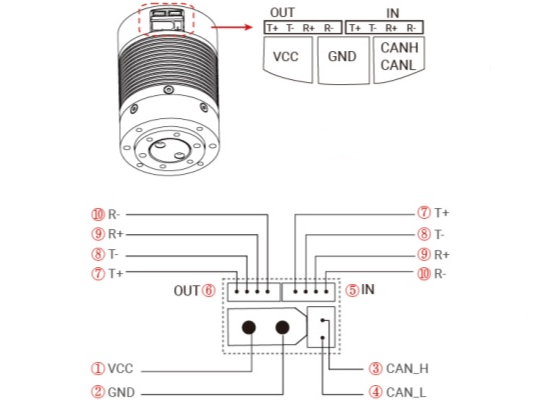

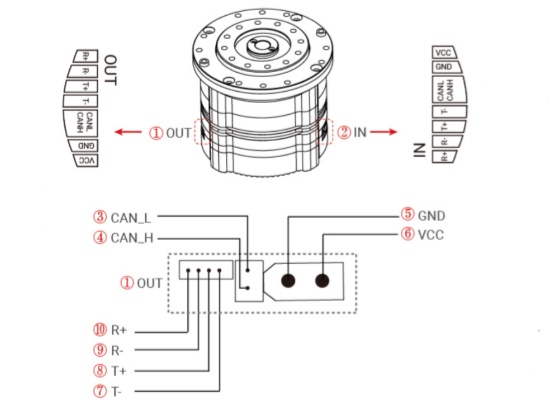

Interface Information

EX Y-2-P28-7-X-N | |

EX Y-4-P36-36-X-N | |

Port Definition | Port Description |

① VCC | Positive power supply |

② GND | Negative power supply |

③ CAN_H | CAN_H network signal terminal |

④ CAN_L | CAN_L network signal terminal |

⑤ EtherCAT_IN | EtherCAT input terminal |

⑥ EtherCAT_OUT | EtherCAT output terminal |

⑦ T+ | Master sends control commands to module |

⑧ T- | Module sends status feedback to master |

⑨ R+ | Master reflects module status data |

⑩ R- | Module reflects master control commands |

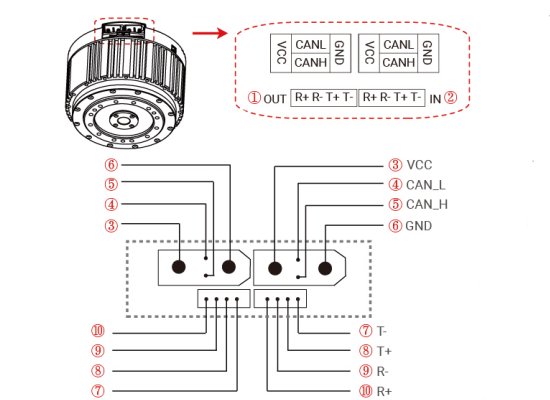

EX Y-6-P20-60-X-N | |

EX Y-8-P20-120-X-N | |

Port Definition | Port Description |

① EtherCAT_OUT | EtherCAT output terminal |

② EtherCAT_IN | EtherCAT input terminal |

③ CAN_L | CAN_L network signal terminal |

④ CAN_H | CAN_H network signal terminal |

⑤ GND | Negative power supply |

⑥ VCC | Positive power supply |

⑦ T- | Module sends status feedback to master |

⑧ T+ | Master sends control commands to module |

⑨ R- | Module reflects master control commands |

⑩ R+ | Master reflects module status data |

EX Y-12-P20-320-X-N | |

EX Y-15-P20-450-X-N | |

Port Definition | Port Description |

① EtherCAT_OUT | EtherCAT output terminal |

② EtherCAT_IN | EtherCAT input terminal |

③ VCC | Positive power supply |

④ CAN_L | CAN_L network signal terminal |

⑤ CAN_H | CAN_H network signal terminal |

⑥ GND | Negative power supply |

⑦ T- | Module sends status feedback to master |

⑧ T+ | Master sends control commands to module |

⑨ R- | Module reflects master control commands |

⑩ R+ | Master reflects module status data |

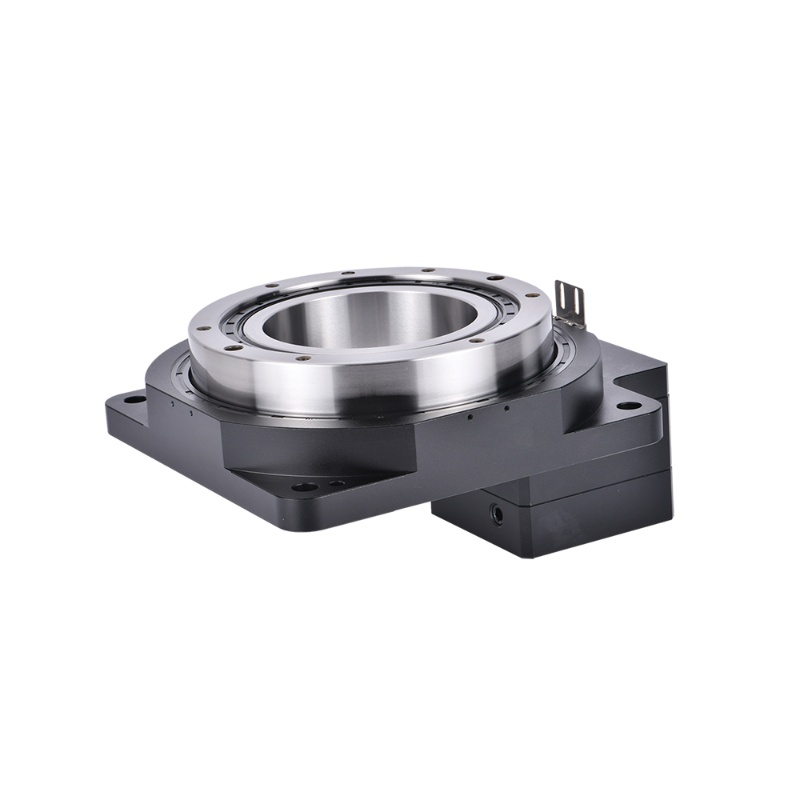

Application

The planetary EX series special reduction motors are designed for robot arm joints. They have dual encoders, high precision, high rigidity and low backlash characteristics, which can meet the precise control requirements of different load scenarios. This series of motors are widely used in industrial robots, collaborative robots, automated production lines, medical robot arms, logistics sorting systems and precision assembly equipment to ensure stable transmission and precise positioning under high-speed operation. Its compact structure, high torque density and long life design can effectively improve the dynamic response capability and durability of the robot arm. It is suitable for automated operation scenarios with high repeatability requirements, and helps intelligent manufacturing and flexible production

Product parameters

Parameter Unit | Unit | Y2-7 | Y4-10 | Y4-36 | Y6-60 | Y8-120 | Y12-320 | Y15-450 |

Reduction ratio | - | 28.17 | 12.6 | 36 | 19.612 | 19.612 | 20 | 20.25 |

Input voltage | V | 24 | 24 | 24 | 48 | 48 | 48 | 72 |

No-load speed | RPM | 178 | 317 | 111 | 176 | 158 | 125 | 93 |

No-load input current | A | 1 | 1 | 0.9 | 0.9 | 1.6 | 27 | 3.5 |

Rated speed | RPM | 142 | 238 | 83 | 153 | 127 | 100 | 74 |

Rated torque | N.m | 2.5 | 4 | 11.5 | 20 | 43 | 85 | 145 |

Rated output power | W | 37 | 100 | 100 | 320 | 574 | 1000 | 1124 |

Rated phase current | A(rms) | 3 | 7.8 | 6.1 | 9.5 | 17.6 | 30 | 25 |

Peak torque | N.m | 7 | 10 | 34 | 60 | 110 | 320 | 450 |

Peak phase current | A(rms) | 8.1 | 19.5 | 21.5 | 29.1 | 43.8 | 100 | 69.2 |

Efficiency | % | 63 | 69.5 | 63.1 | 72.7 | 79 | 75 | 824 |

Motor back EMF constant | Vdc/Krpm | 4.3 | 6 | 6 | 16 | 19.2 | 17.9 | 29.9 |

Module torque constant | N.m/A | 0.8 | 0.8 | 1.9 | 21 | 24 | 3.3 | 5.8 |

Motor resistance | Ω | 0.61 | 0.32 | 0.35 | 0.41 | 0.18 | 0.12 | 0.08 |

Motor line inductance | mH | 0.13 | 0.14 | 0.17 | 0.51 | 0.31 | 0.05 | 0.14 |

Number of pole pairs | - | 13 | 13 | 13 | 10 | 10 | 20 | 20 |

Tooth slot torque | mN.m | 20 | 30 | 50 | 30 | 50 | 1420 | 1480 |

Wiring method | - | Y | Y | Y | Y | Y | Y | Y |

Back drive torque | N.m | 0.4 | 0.8 | 1.14 | 1.6 | 3.21 | 3.8 | 4 |

Backlash | Arcmin | 12 | 10 | 10 | 10 | 10 | 10 | 10 |

Axial load - tension | KN | 0.25 | 1.2 | 13 | 1.8 | 4 | 4.5 | 5.4 |

Axial load - compression | KN | 0.25 | 1.2 | 13 | 0.8 | 1 | 4.5 | 5.4 |

Radial load | KN | 1 | 1.2 | 1.5 | 2 | 4.5 | 5 | 6 |

Moment of inertia | Kg.cm² | 0.17 | 0.25 | 0.3 | 0.66 | 1.5 | 129 | 31.6 |

Encoder type | - | Dual Encoder ABS-17BIT(Input)/18BIT(Output) | Dual Encoder ABS-17BIT (Input)/17BIT (Output) | |||||

Repeat positioning accuracy | Degree | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

Communication method | - | CAN BUS /EtherCAT | CAN/EtherCAT | CAN BUS /EtherCAT | ||||

Weight | Kg | 0.26 | 0.26 | 0.36 | 0.82 | 1.4 | 26 | 3.6 |

Insulation level | - | F | F | F | F | F | F | F |

Rated torque test method:

When the ambient temperature is 24 degres Celsius(no other heat dissipation methods).the test is performed at the rated speed, the motor torque reacheds tmeperature balance under the condition of a temperature ris of 60 degree Celsius, and the long-term working point is the rated torque valuce of the motor.

Model | Torque (N.m) | Temperature rise (℃) | Stall time (s) | Phase current (Arms) |

X2-7 | 3.75 | 20 | 15 | 4.3 |

5 | 48 | 10 | 5.7 | |

6.25 | 31 | 8 | 7.4 | |

7.5 | 59 | 5 | 8.6 | |

X4-10 | 5.2 | 41 | 10 | 7.8 |

6 | 16 | 8 | 9.1 | |

7.2 | 26 | 5 | 11 | |

8 | 30 | 3 | 12.1 | |

X4-36 | 17.25 | 30 | 15 | 9.2 |

23 | 58 | 10 | 12.7 | |

28.75 | 41 | 5 | 16.3 | |

34.5 | 50 | 3 | 21.2 | |

X6-60 | 30 | 17 | 15 | 12.7 |

40 | 29 | 10 | 17.7 | |

50 | 37 | 8 | 22.6 | |

60 | 24 | 5 | 28.3 | |

X8-120 | 64.5 | 7 | 15 | 23.3 |

86 | 10 | 10 | 31.1 | |

107.5 | 26 | 8 | 38.9 | |

129 | 30 | 5 | 43.8 | |

X15-450 | 217.5 | 15 | 15 | 31.1 |

290 | 15 | 10 | 41 | |

362.5 | 20 | 8 | 51.6 | |

435 | 25 | 5 | 67.2 |

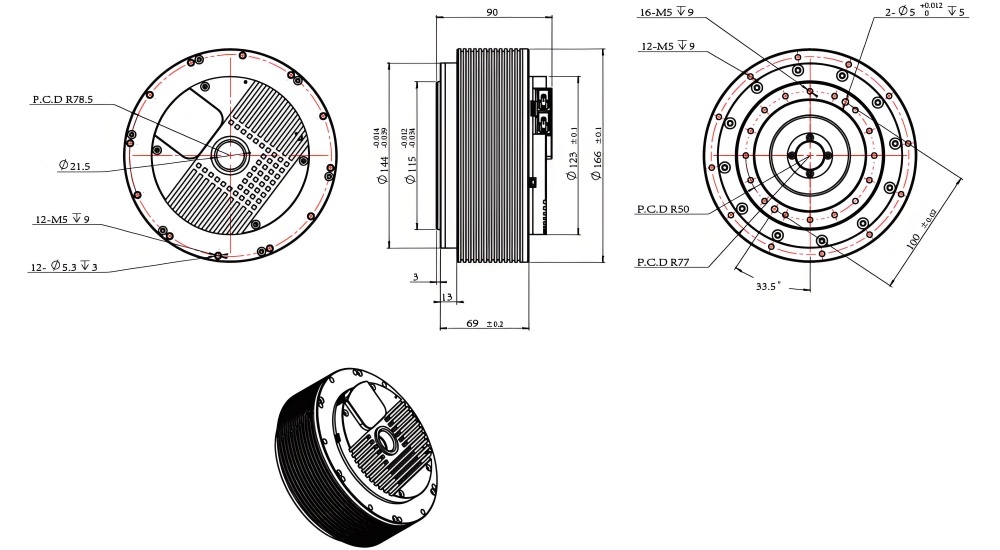

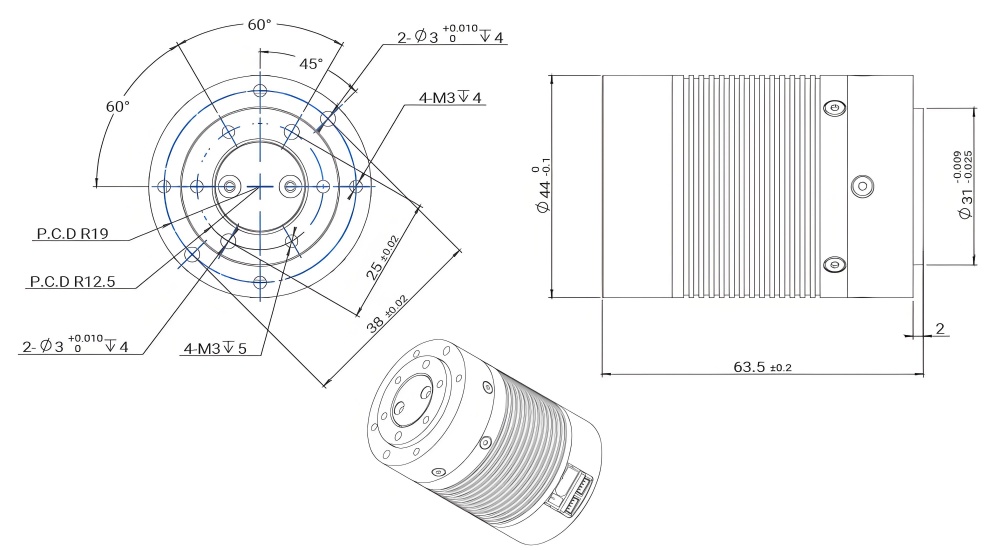

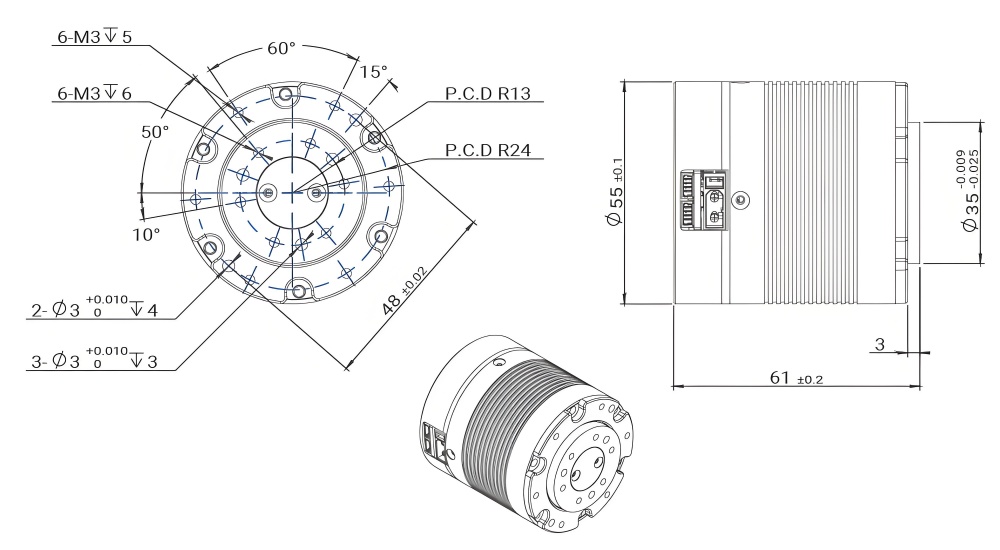

EX Y-2-P28-7-X-N

EX Y-4-P12-10-X-N

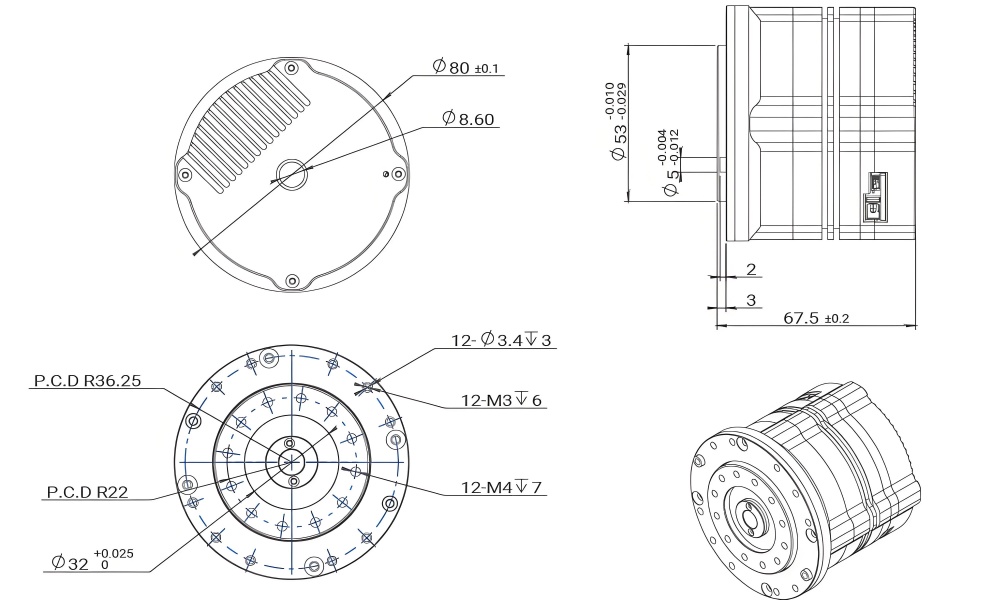

EX Y-4-P36-36-X-N

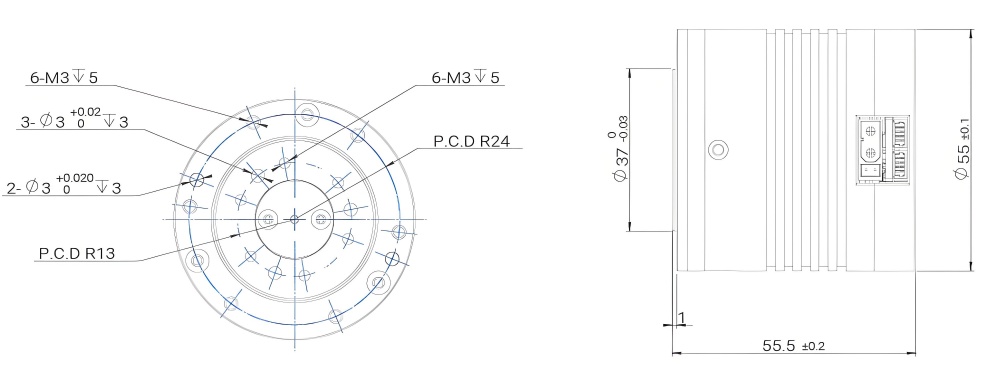

EX Y-6-P20-60-X-N

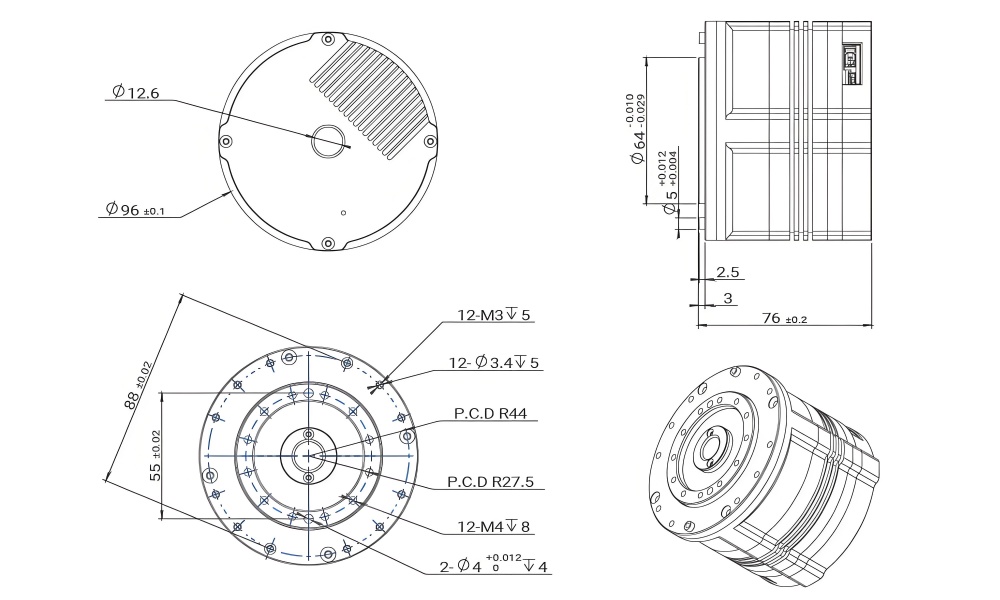

EX Y-8-P20-120-X-N

EX Y-12-P20-320-X-N

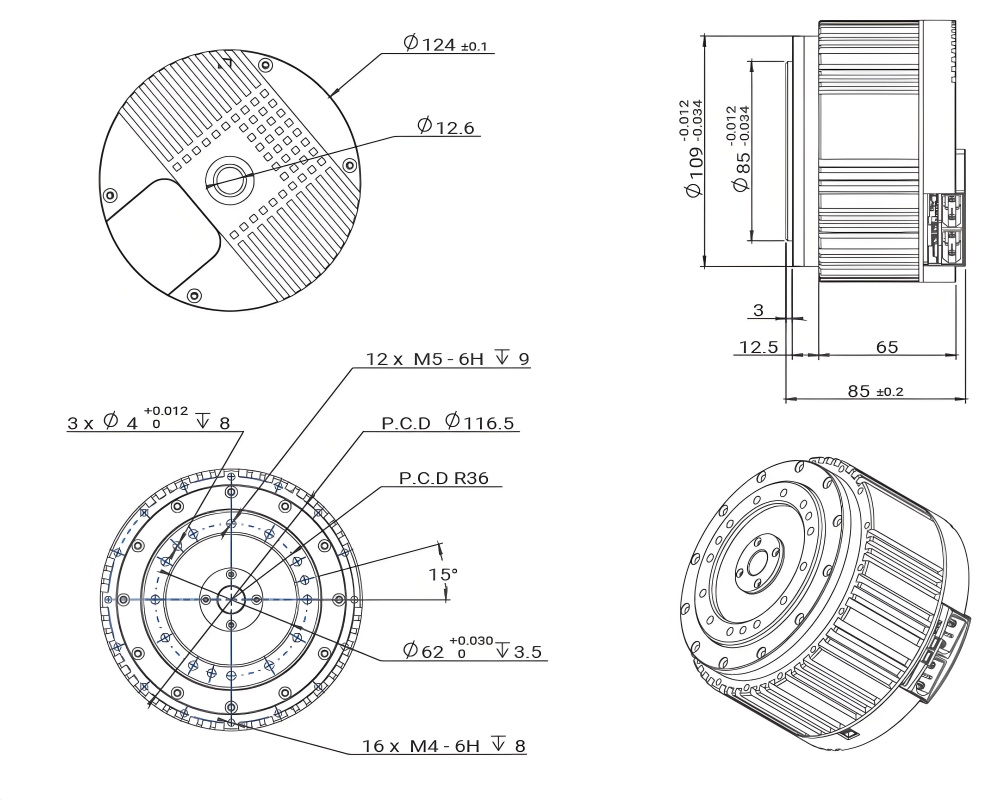

EX Y-15-P20-450-X-N