Product Description

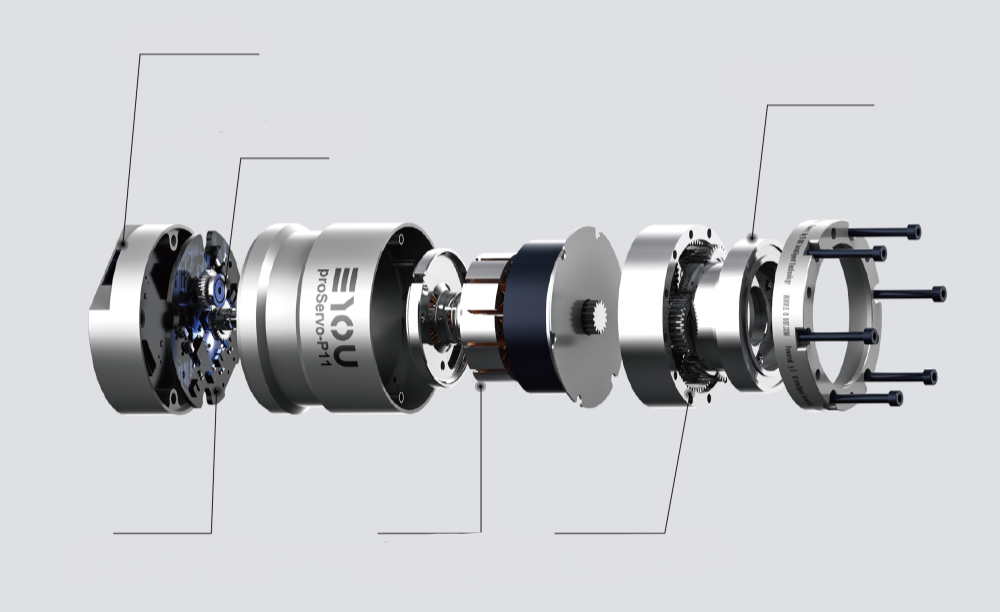

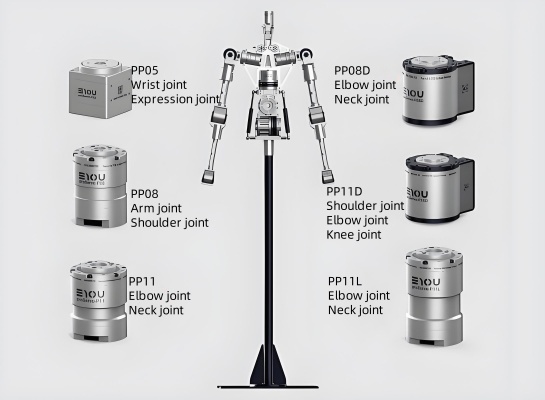

The integrated servo joint product is a micro-servo joint with integrated drive and control that highly integrates a precision planetary reducer, torque motor, and professional servo drive. The joints are connected in series through the bus. The wiring is simple and easy to operate, and the overall failure rate of the machine is low. The product is compact in size and has a large torque, making it particularly suitable for multi-joint combination application scenarios such as bionic robots, bionic animals, and educational mechanical arms. At the same time, due to its high cost performance and stable performance, it can replace various brushless motors and high-torque servos.

CAN2.0 bus, Interface frequency: 1MHZ

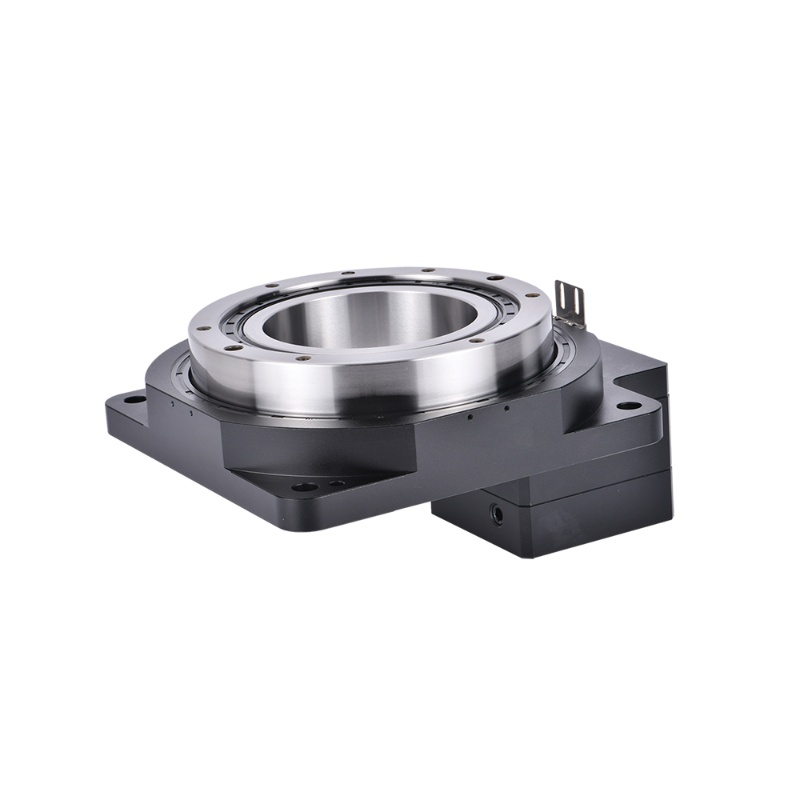

Four-point contact bearings, capable of withstanding axial and radial loads

The mechanical dual encoder has an accuracy of 18 bits *2

Full hardness FOC drive, 20KHZ closed-loop period High-density frameless torque motor Precision planetary reducer, high strength and low noise

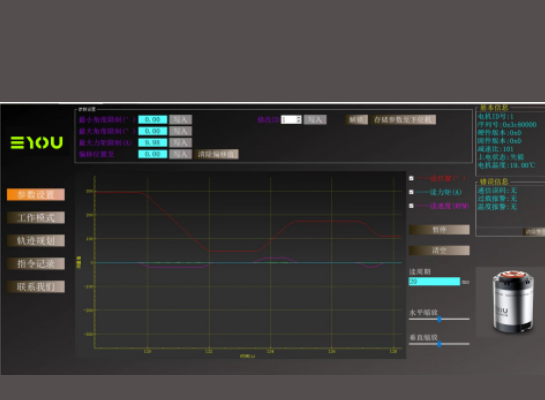

Complete parameter Settings

Position contour working mode

Acceleration and deceleration, origin, Angle limit, torque limit,

high and low temperature limit, etc. can all be set freely

Product Display

The PP series planetary servo motors adopt ultra-high torque, high-precision metal gears, low cogging torque, high-density brushless external rotor torque motors. The motor end accuracy is 16-bit, and the output end has a single-turn absolute value. The power loss Angle is not lost, and no external battery is required. The internal integrated trajectory contour working mode enables various working modes to be freely realized.

Application

The PP series planetary joint modules are widely used in high-precision and high-load motion control scenarios, such as the joint drive of industrial robots, to achieve flexible multi-axis coordination. The end effector of the collaborative mechanical arm ensures smooth and precise operation; The rotary indexing table in the automated production line improves the positioning efficiency; And the wind power pitch control system, which withstands extreme loads. Its compact integrated design, high torque output and low backlash characteristics significantly enhance the dynamic performance and reliability of the equipment, making it suitable for harsh industrial environments.

Product parameters

Model | PP05 | PP08/PP08D | PP11/PP11D | PP11L |

Motor type | Brushless torque motor | |||

Reducer type | Planetary reducer | |||

Diameter | 32mm | 40mm | 52mm | 52mm |

Length | 33.4mm | 52/48mm | 64/61mm | 82mm |

Weight | 82g | 190/199g | 391/436g | 517g |

Reduction ratio | 6:1 | 36:1 | ||

Reverse backlash | 12arcmin | |||

Noise | <70db | |||

Temperature range | -20 - 80°C | |||

Working voltage | 24v | |||

Maximum power | 35w | 36w | 60w | 72w |

Rated rotational speed | 50rpm | |||

Rated torque | 0.2nm | 1.0nm | 6.6nm | 12nm |

Peak torque | 0.48nm | 2.2nm | 14nm | 18nm |

Torque coefficient | 0.2nm/A | 1.1nm/A | 2.2nm/A | 6nm/A |

Axial bearing capacity | - | 1284N | 1605N | 1605N |

Radial bearing force | - | 2520N | 3150N | 3150N |

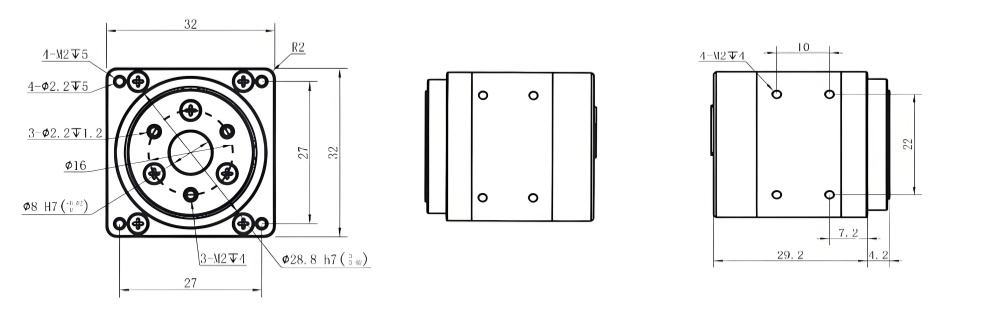

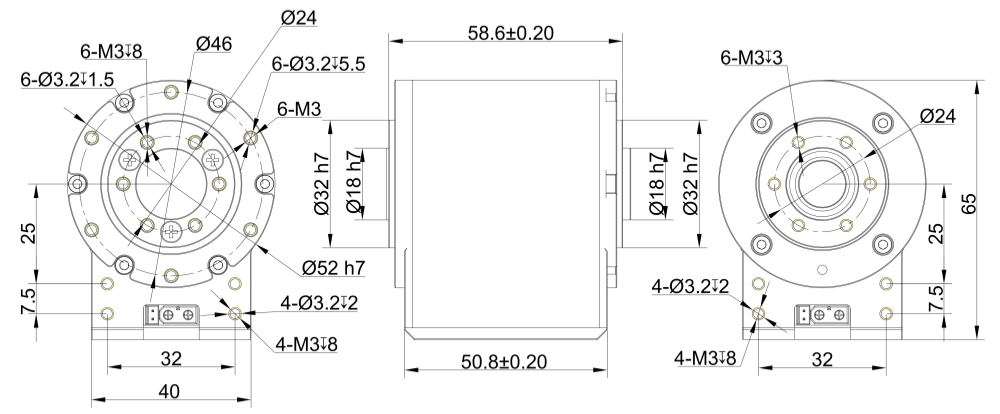

PP05-6

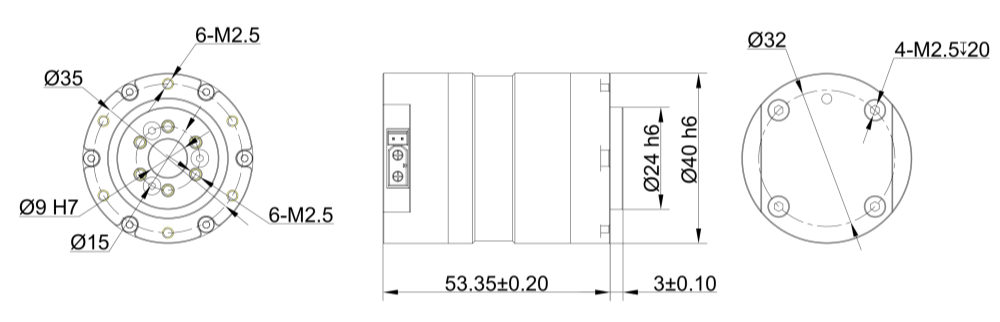

PP08-36

PP08D-36

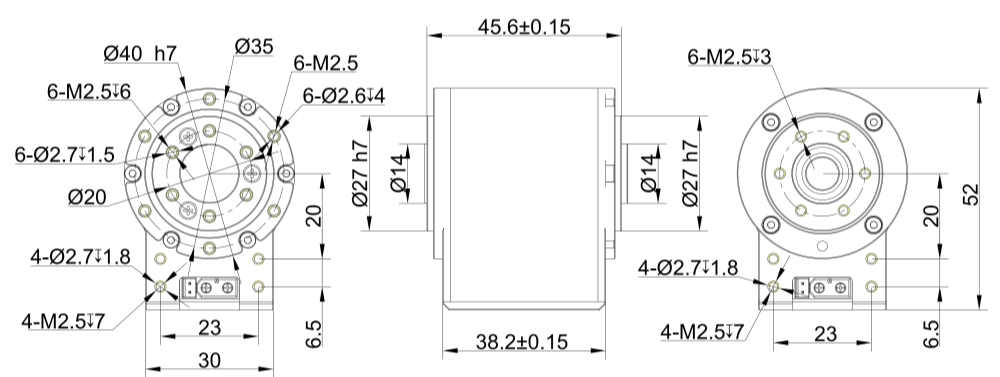

PP11-36

PP11-36D

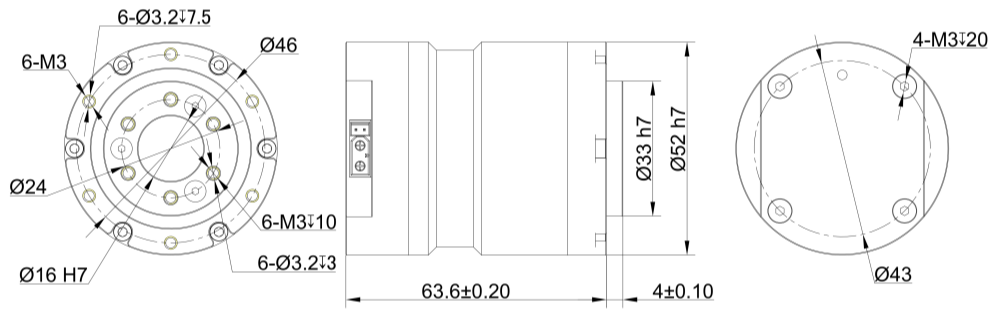

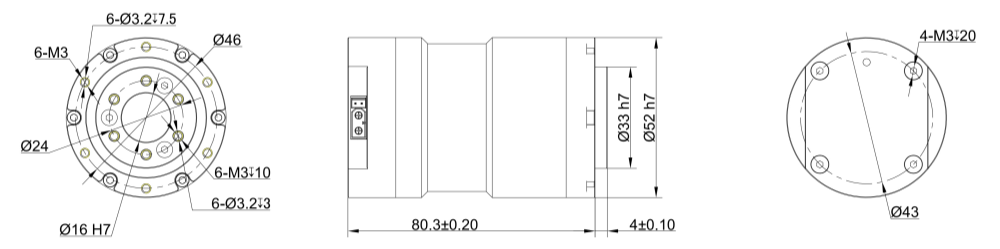

PP11L-36

Service

1. Does it support customizing the reduction ratio?

This series of reduction ratios offers 6:1 and 36:1. If there are special requirements, other products in the store can be customized or recommended.

2.What are the differences between the single encoder and dual encoder versions?

The single encoder version monitors the rotation at the motor end and is suitable for applications with general precision requirements.

The dual-encoder version simultaneously monitors the motor end and output end, effectively compensating for backlash and elastic errors. It is suitable for high-precision control and applications with high safety requirements (such as collaborative robots and medical equipment). This series offers 18-bit dual encoders.

3. What communication interfaces can the joint module support?

The standard version supports analog control (current/voltage command) or pulse command control.

This series supports the CAN bus protocol and can provide customization or other model suggestions.

4. Does it support integrated drive and control? Can it be directly connected to the controller?

We offer an optional drive and control integrated joint module with built-in motor drivers and position servo controllers.

Users can directly control it through the bus or pulse interface without the need for an external independent driver, simplifying wiring and system integration.

5. Are there any standard 3D model files available for download?

Yes. We provide 3D model files in STEP format for all models to facilitate customers' rapid integration of mechanical design.

If you need to obtain it, please contact our sales staff to get the download link or the material package.

6. Can the joint module be designed to be hollow? Can the wires be routed?

This model features both hollow shaft and solid designs.

The central hole diameter can be used for wiring, air pipes, water pipes, etc., facilitating the functional layout of complex end effectors.

For specific center aperture dimensions, please refer to the model selection table or consult customer service.

7. How long are the standard delivery time and the customized delivery time?

The delivery time for standard models is usually 7 to 14 working days.

The delivery time for customized requirements (such as IP56 waterproofing, customized reduction ratio, customized communication protocol, etc.) is determined

by specific requirements and is generally 5 to 10 weeks.

8. How long is the warranty period? How about the after-sales service?

All joint module products come with a 12-month warranty period (under normal usage conditions).

We offer remote technical support, fault diagnosis guidance, and rapid spare parts supply services.

Paid repair and maintenance services can also be provided outside the warranty period.