Product Description

HIGH SMOOTHNESS LOW NOISE HIGH EFFICIENCY

STRONG CARRYING CAPACITY PRECISE CONTROL EASY TO OPERATE

Product Highlights:

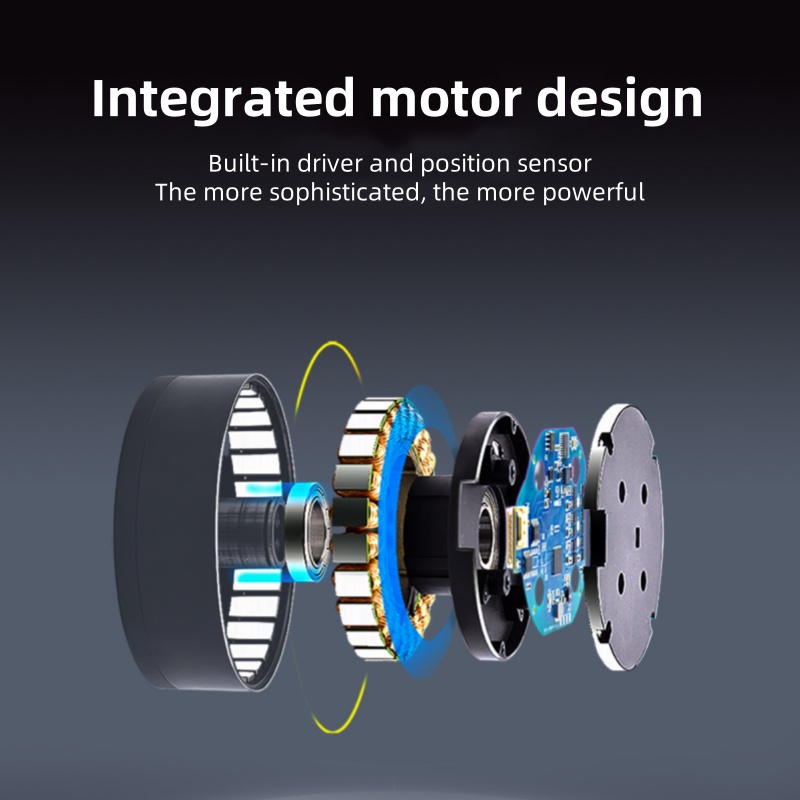

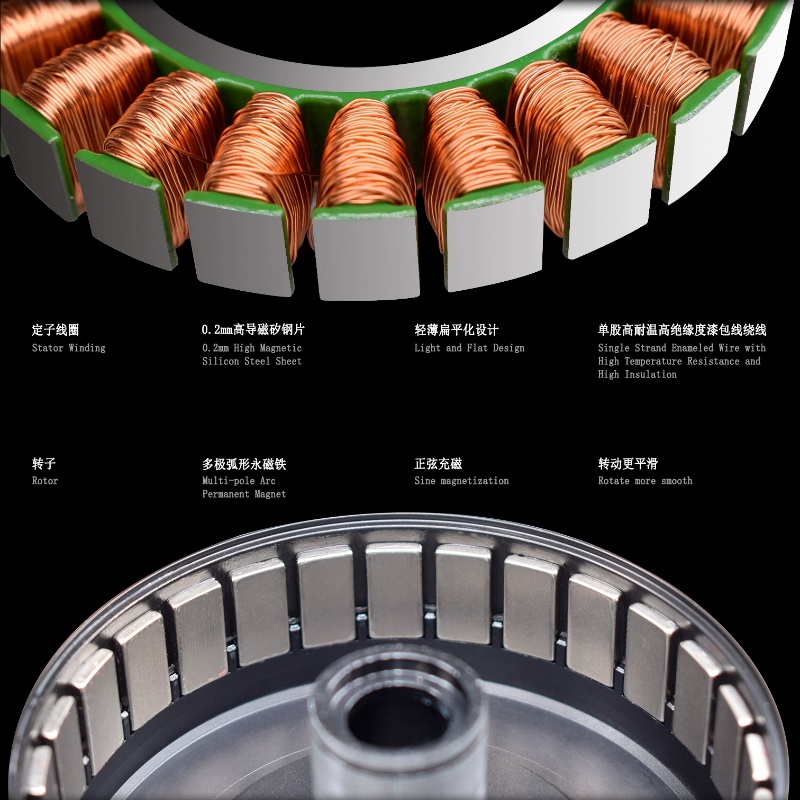

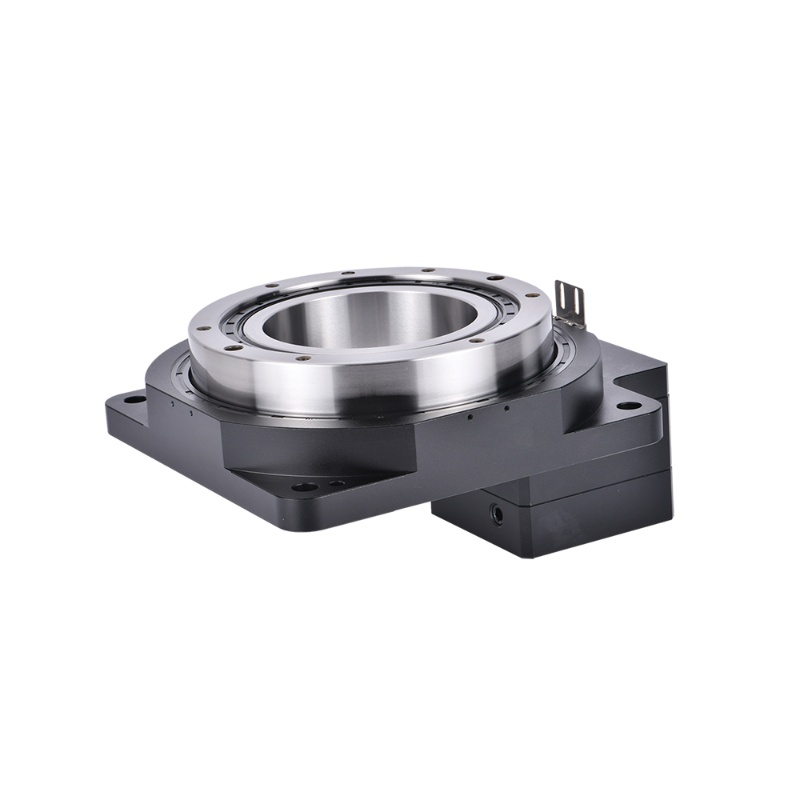

The EL Series robotic joint modules are engineered for high-performance automation with six core advantages: smooth operation, low noise, high efficiency, strong load capacity, precise control, and easy operation. Featuring an all-in-one drive design, each module integrates the motor, reducer, and encoder, reducing wiring complexity and installation space while significantly improving system stability and efficiency. With 10 models available (from EL-4005 to EL-9025), the series covers a wide range of torque and size requirements for flexible configuration.

Performance & Technical Advantages:

The EL Series offers high torque, high speed, and a hollow shaft structure, making it ideal for collaborative robots, AGV/AMR platforms, and intelligent actuators. With support for both CANBUS and RS485 communication protocols, the modules are compatible with various control systems, enhancing development flexibility and integration ease. The robust and reliable structural design, backed by our deep R&D and manufacturing expertise, ensures industry-leading dynamic performance and precision control—making the EL Series the ideal choice for high-performance intelligent systems.

Application

The EL Series joint modules are widely applied across a variety of intelligent equipment and automation systems, including robotic arms, pipeline inspection robots, exoskeleton robots, LiDAR units, AGV intelligent trucks, and gimbal systems. With features like high integration, large torque, hollow structure, and versatile communication interfaces, the EL Series excels in space-constrained, precision-demanding, and fast-response applications. From industrial automation and medical rehabilitation to smart mobility and security monitoring, the EL Series delivers stable, precise, and flexible motion and control solutions for advanced system development.

Robotic Arm

Pipe Robot

Exoskeleton Robots

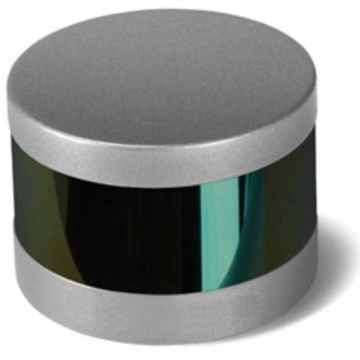

Lidar

AGV Smart Truck

Gimbal

Choosing the EH series joint module means choosing efficient development, reliable performance and broad adaptability. We are committed to providing more intelligent and flexible motion control solutions for global developers, integrators and end users to help your robot products quickly achieve a leap from conception to implementation.

Product parameters

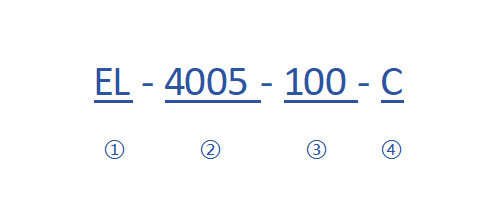

The following is a selection introduction of this series of products for your reference:

① EL Stands For The Series Name: Integrated Hollow Direct Drive Robot Joint Module

② 70 Represent Motor Model Number e.g:4005 5005 7015 etc

③ Rated Power 100W

④ Communication C:CANbus R:RS485 E:Ethercat

For example:

Model EL-5005-100-C

illustrate EL:Integrated Hollow Direct Drive Robot Joint Module 5005:Motor Model Number

100:Rated power C:CAN BUS Communication

Parameters | EL4005 | EL4010 | EL4015 | EL5005 | EL5010 | EL5015 | EL7015 | EL7025 | EL9015 | EL9025 |

Nominal Voltage(V) | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

Nominal Current(A) | 1.44 | 1.43 | 1.88 | 1.67 | 1.65 | 1.57 | 3.62 | 3 | 3.34 | 3.46 |

Nominal Torque(N.m) | 0.07 | 0.15 | 0.22 | 0.13 | 0.26 | 0.36 | 1 | 1.6 | 1.67 | 2.79 |

Nominal Speed(RPM) | 1600 | 560 | 520 | 1360 | 600 | 350 | 580 | 280 | 290 | 130 |

Max Speed(RPM) | 2390 | 1120 | 1010 | 1970 | 1015 | 680 | 805 | 510 | 500 | 280 |

Max Instant Torque(N.m) | 0.25 | 0.33 | 0.49 | 0.42 | 0.65 | 0.82 | 3.8 | 4.1 | 5 | 5.8 |

Max Instant Current(A) | 5.8 | 3.2 | 4.3 | 5 | 4.8 | 3.62 | 15 | 8.5 | 11 | 7.6 |

Line Resistance(Ω) | 1.9 | 3 | 3.3 | 2 | 3.2 | 4 | 1.14 | 2.2 | 1.51 | 1.9 |

Wire Connect | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

Phase to Phase Inductance(mH) | 0.5 | 1 | 0.78 | 0.65 | 1.2 | 1.76 | 1.25 | 2.95 | 1.05 | 4.71 |

Speed Constant(RPM/V) | 199 | 93 | 63 | 123 | 63 | 43 | 34 | 21 | 21 | 12 |

Torque Constant(N.m/A) | 0.05 | 0.1 | 0.12 | 0.08 | 0.16 | 0.23 | 0.28 | 0.53 | 0.45 | 0.76 |

Rotor Inertia(gcm2) | 56 | 81 | 105 | 136 | 202 | 268 | 933 | 1040 | 3271 | 4656 |

Number of Pole Pairs | 13 | 13 | 13 | 14 | 14 | 14 | 14 | 14 | 14 | 14 |

Weight(g) | 65 | 92 | 120 | 92 | 135 | 174 | 360 | 540 | 650 | 880 |

Working Temperature(℃) | -20~55 | -20~55 | -20~55 | -20~55 | -20~55 | -20~55 | -20~55 | -20~55 | -20~55 | -20~55 |

Max Demagnetize Temperature(℃) | 120℃ | 120℃ | 120℃ | 120℃ | 120℃ | 120℃ | 120℃ | 120℃ | 120℃ | 120℃ |

Control Precision(°) | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

Matched Driver | ||||||||||

Driver | MC100 | MC200 | ||||||||

Input Voltage(V) | 12~24 | 12~24 | ||||||||

Current(A) | Normal: 5A | Normal: 8A | ||||||||

Nominal Power(W) | 100 | 200 | ||||||||

Encoder | 18-bit magnetic encoder | 14-bit magnetic encoder | 18-bit magnetic encoder | 14-bit magnetic encoder | 18-bit magnetic encoder | 14-bit magnetic encoder | 18-bit magnetic encoder | 18-bit magnetic encoder | 14-bit magnetic encoder | 14-bit magnetic encoder |

Communication method and baud rate(Kg) | CAN BUS: 1M; | CAN BUS: 1M; | ||||||||

Control mode | Torque loop(current loop)/ speed loop/ position loop | Torque loop(current loop)/ speed loop/ position loop | ||||||||

S-Curve | YES | |||||||||

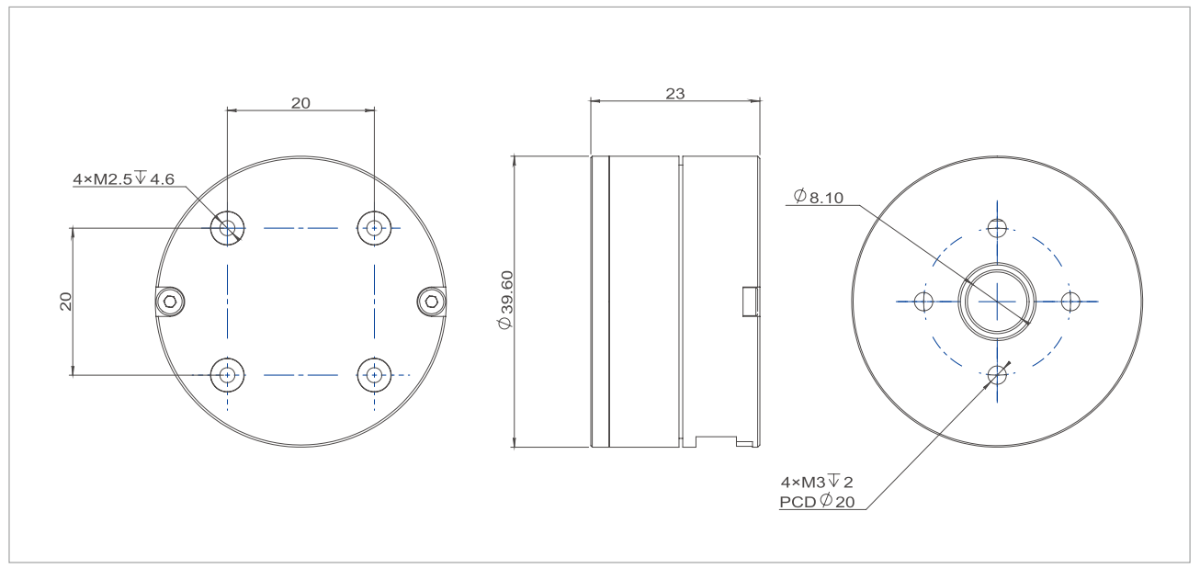

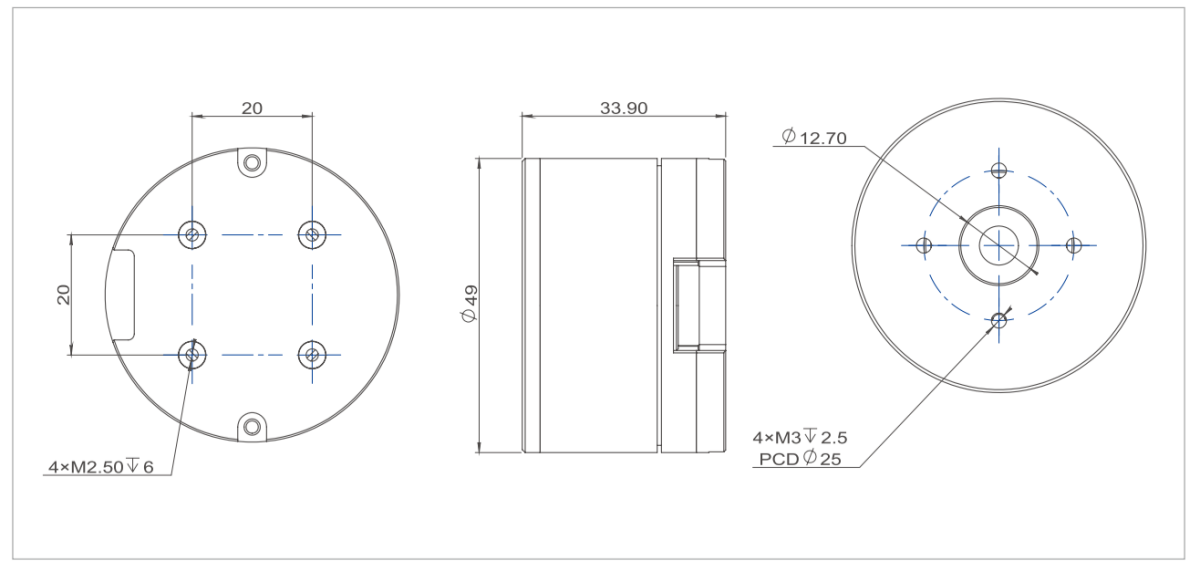

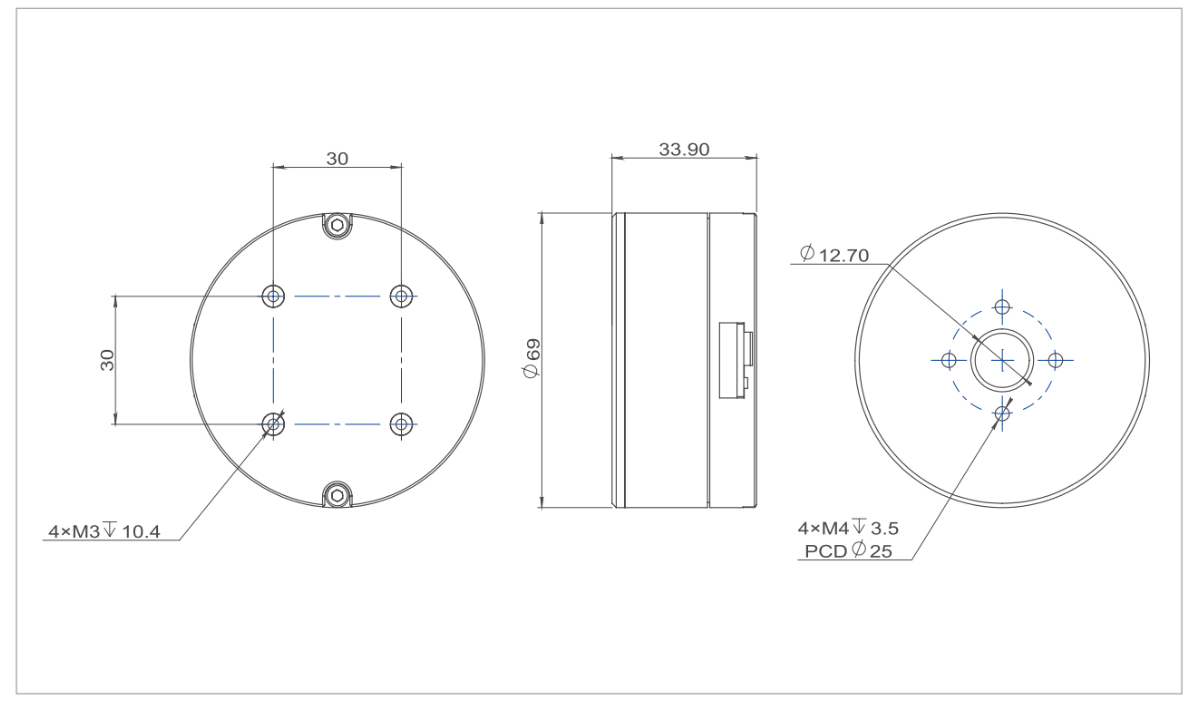

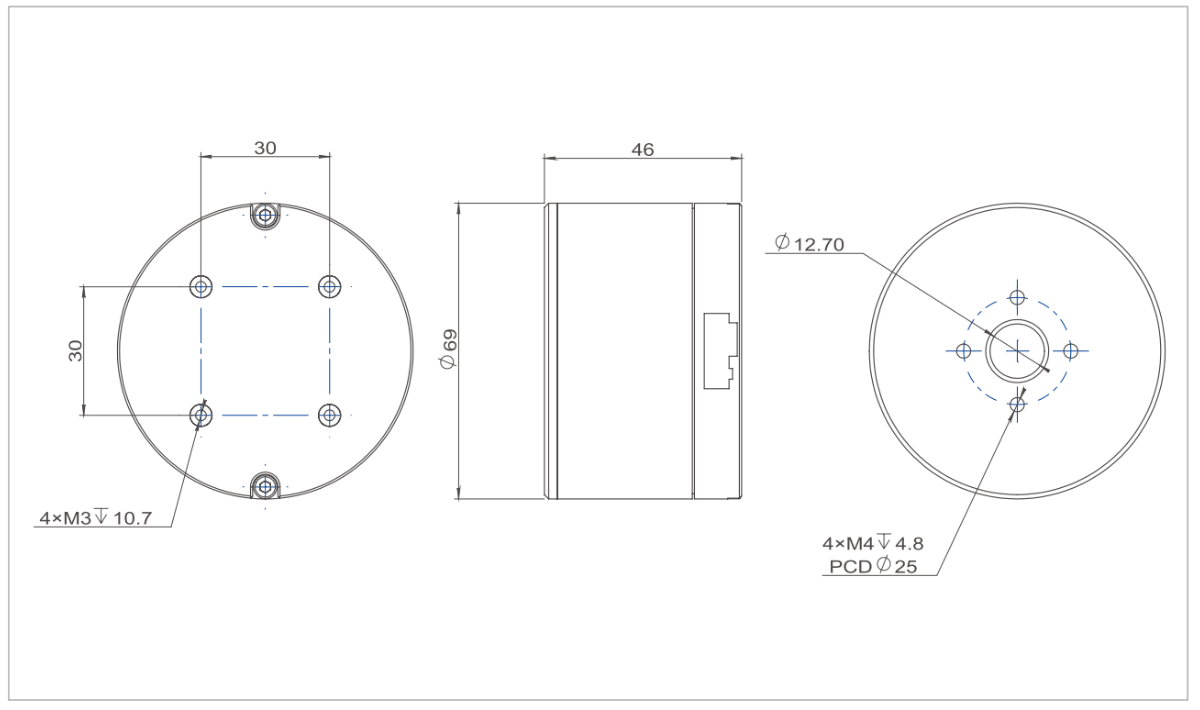

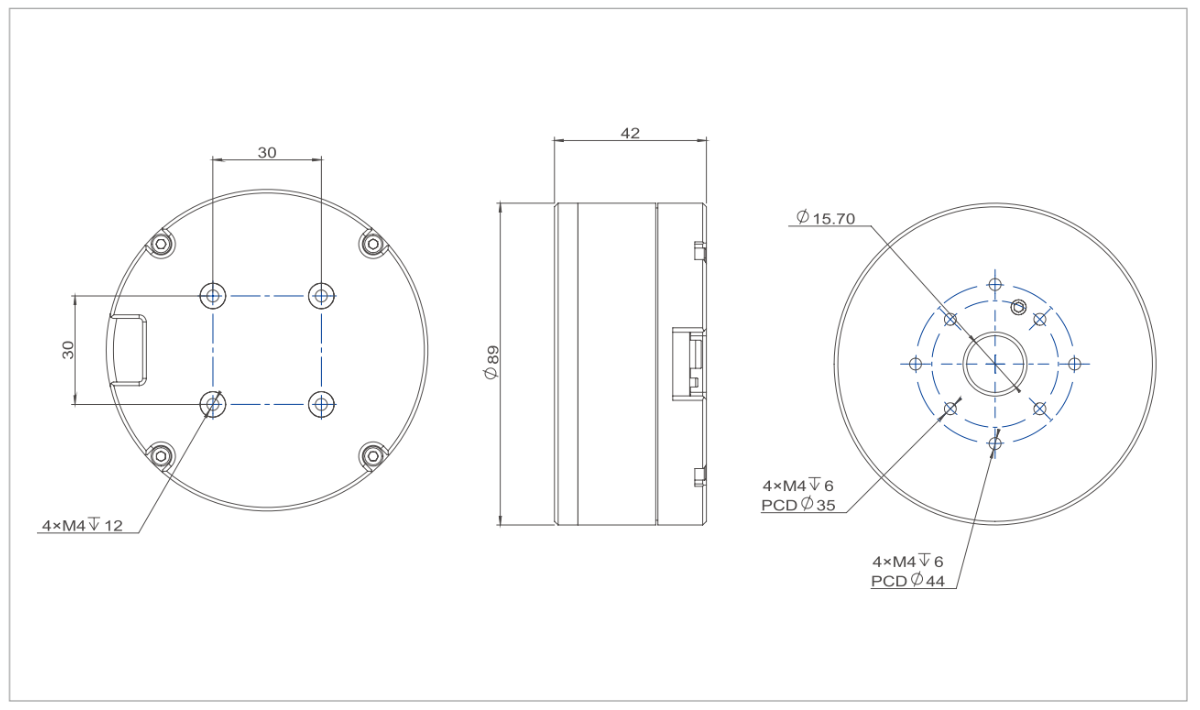

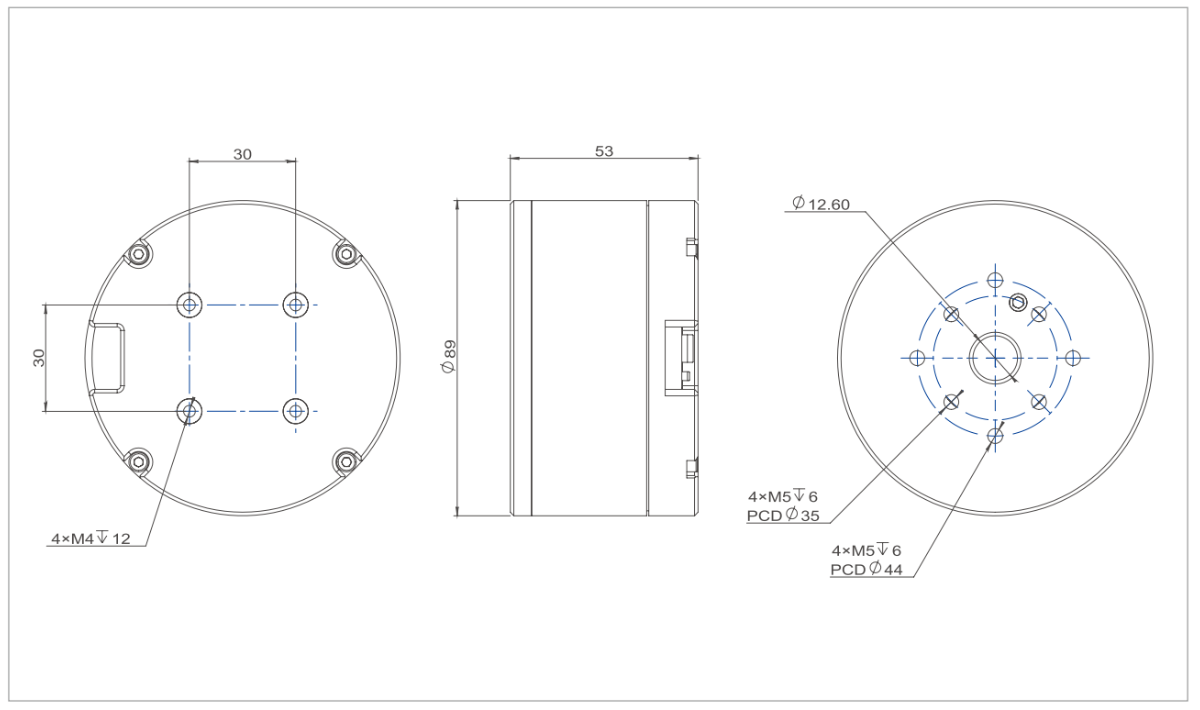

Dimensional Installation Drawing

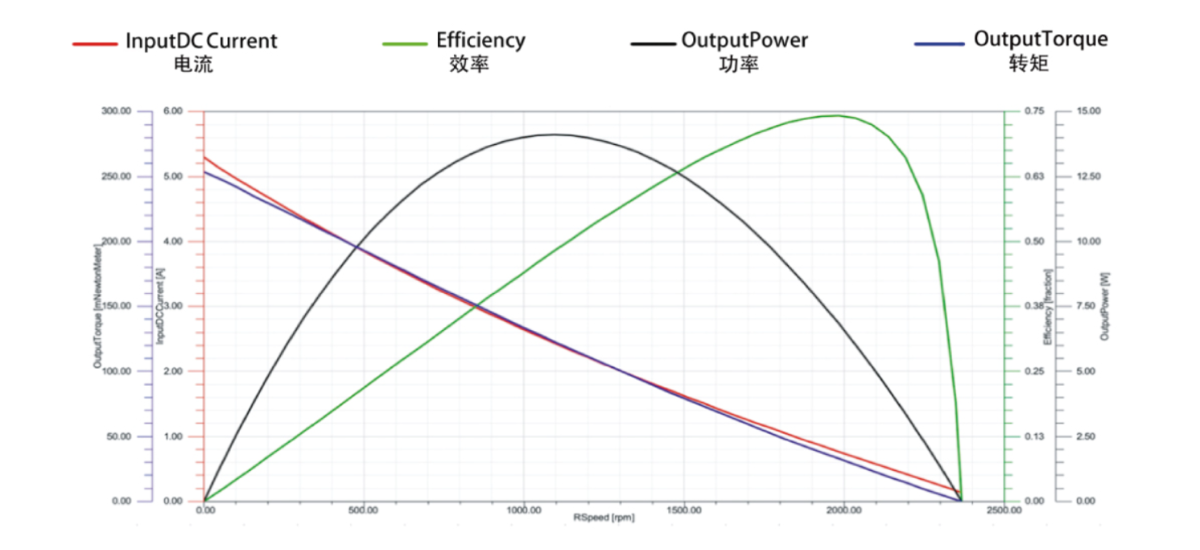

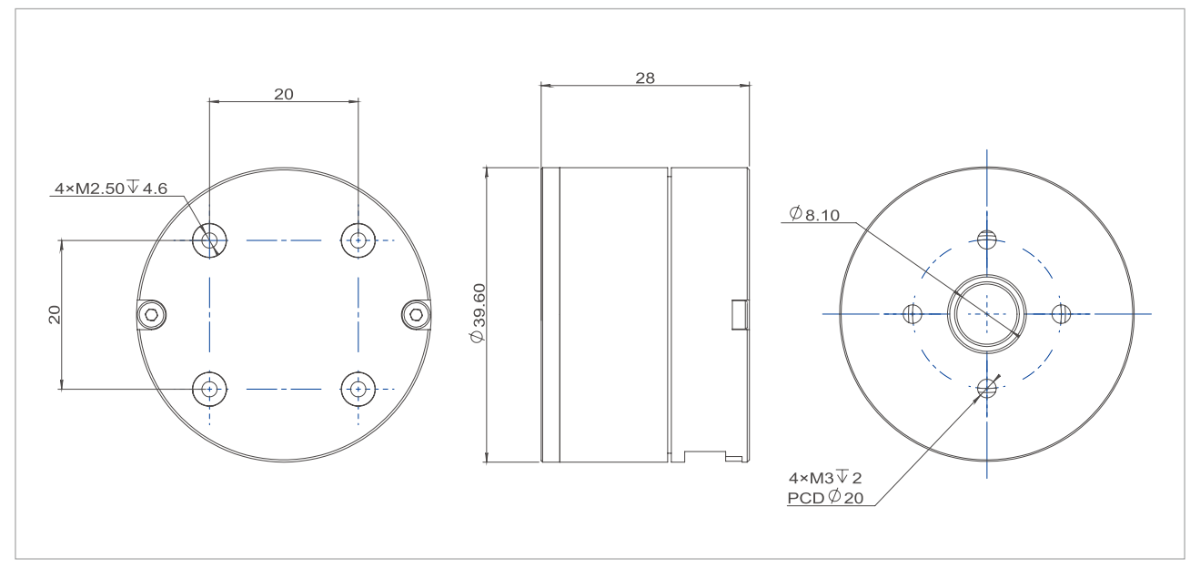

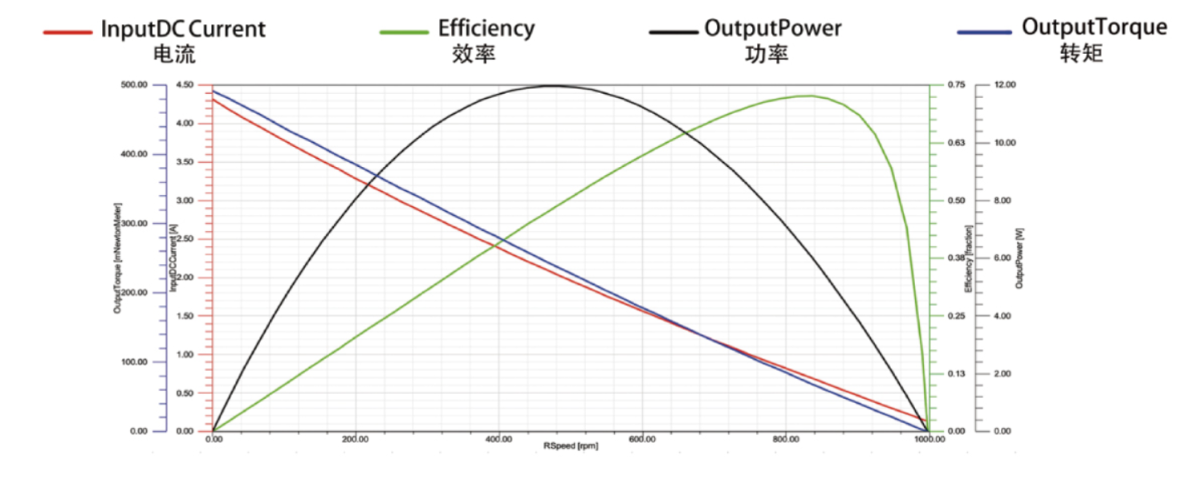

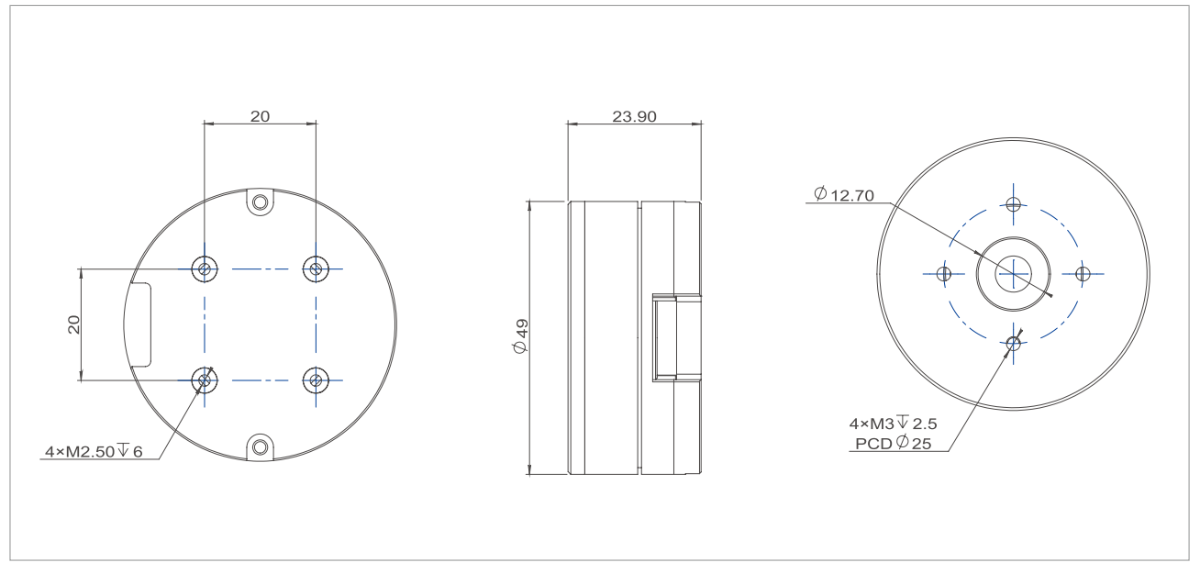

EL-4005

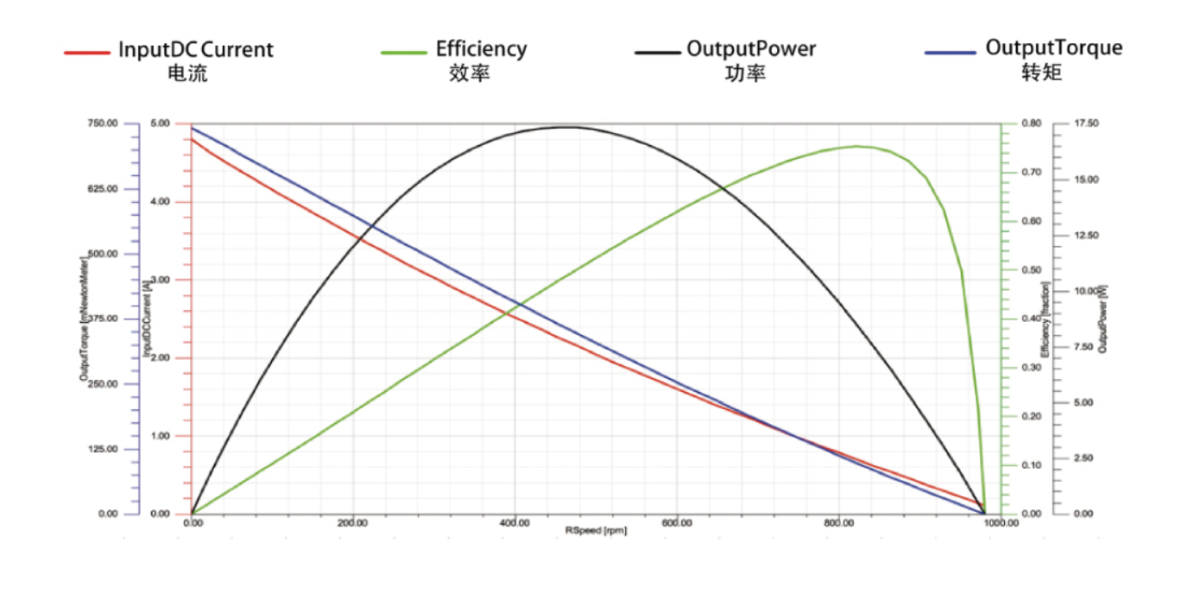

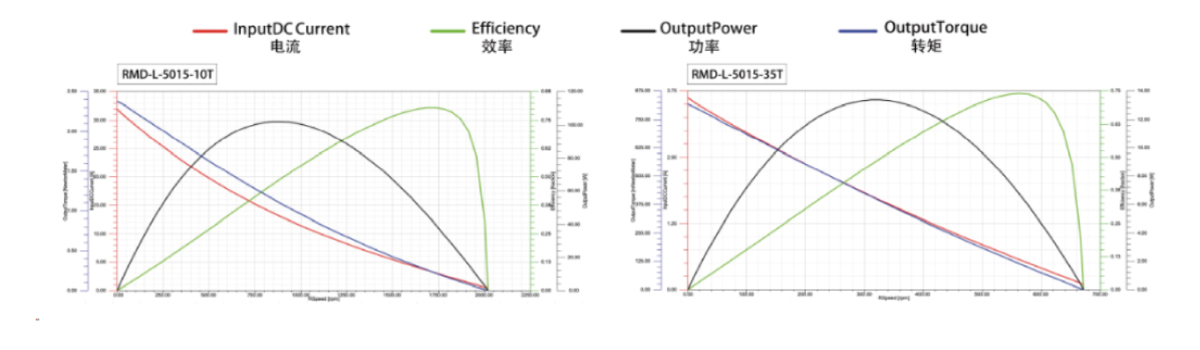

Motor Characteristic Curve

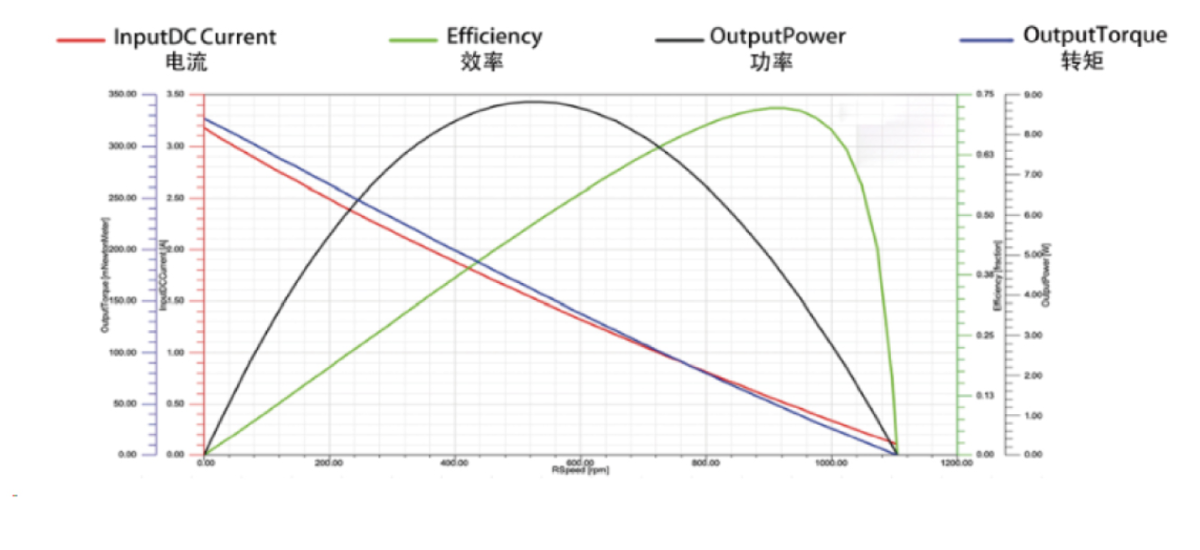

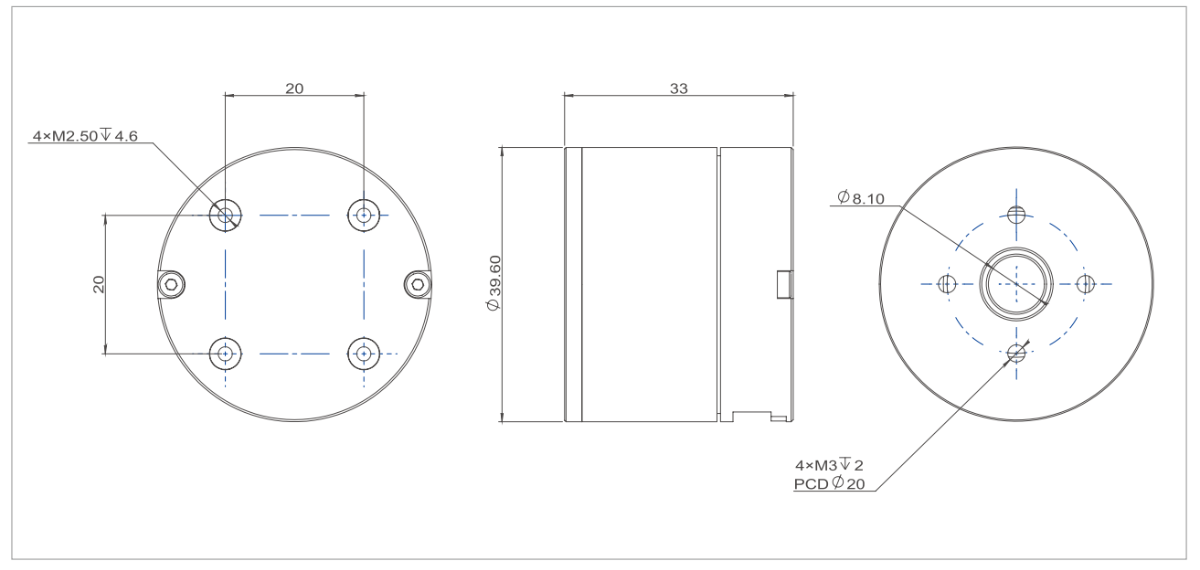

EL-4010

Motor Characteristic Curve

EL-4015

Motor Characteristic Curve

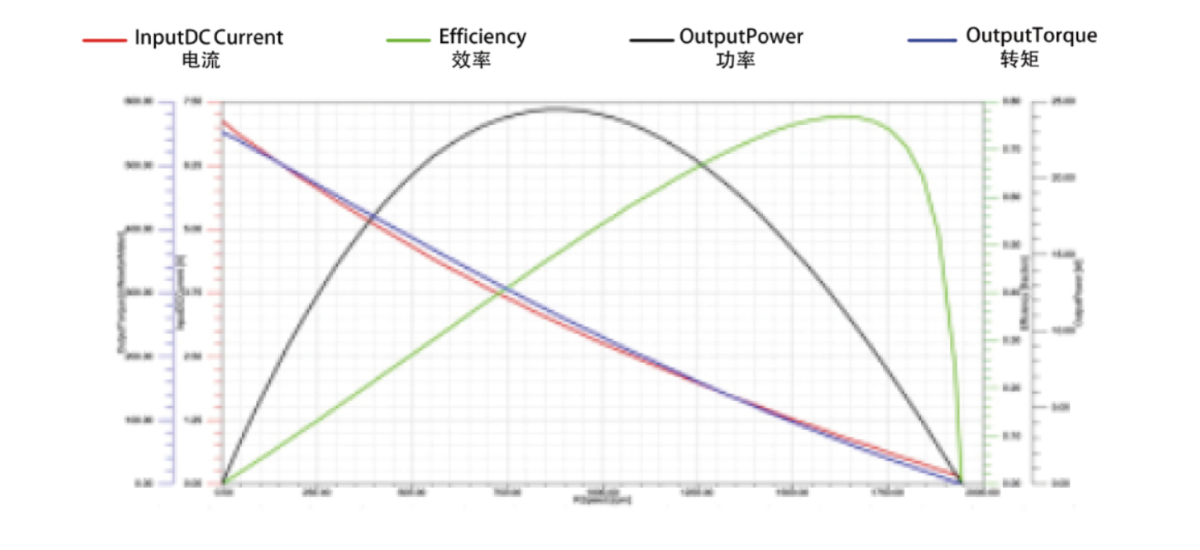

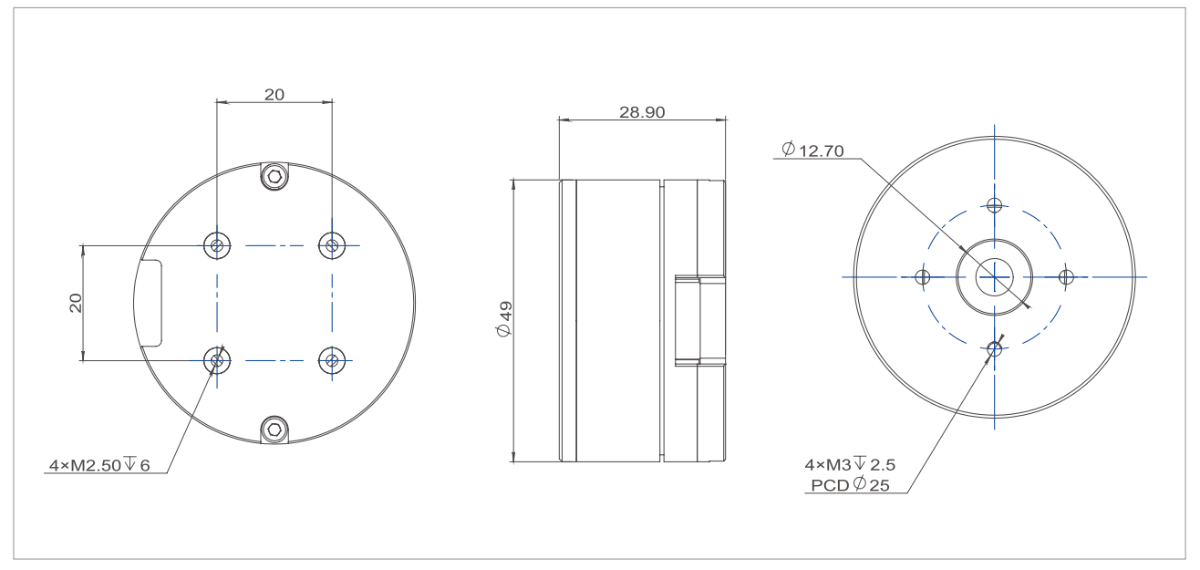

EL-5005

Motor Characteristic Curve

EL-5010

Motor Characteristic Curve

EL-5015

Motor Characteristic Curve

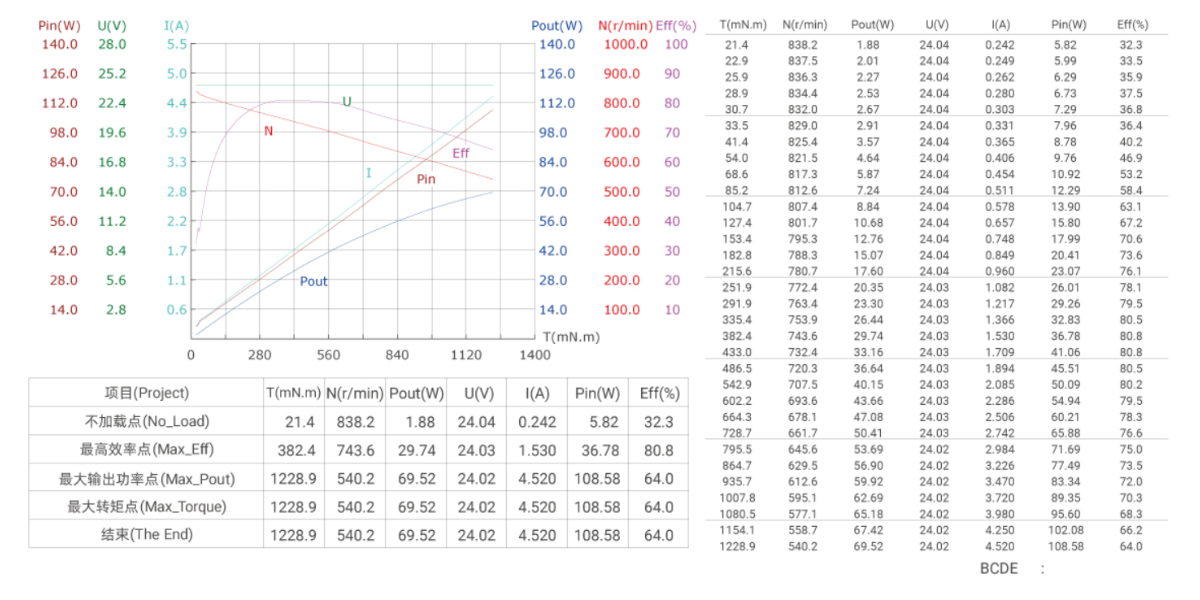

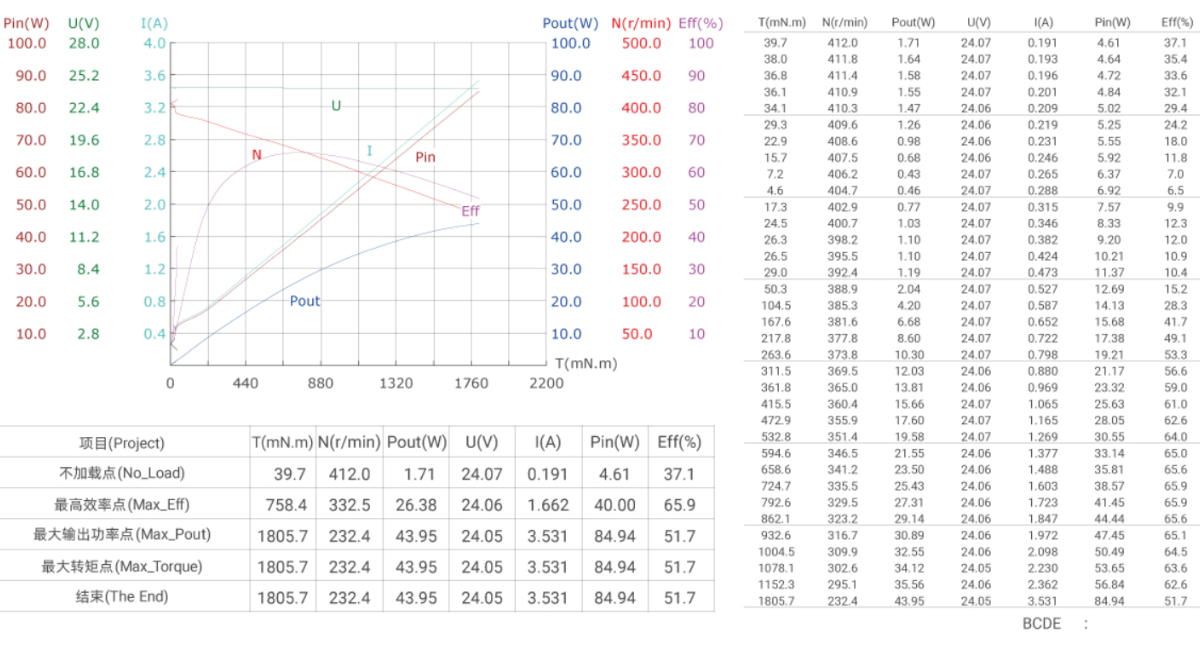

EL-7015

Motor Characteristic Curve

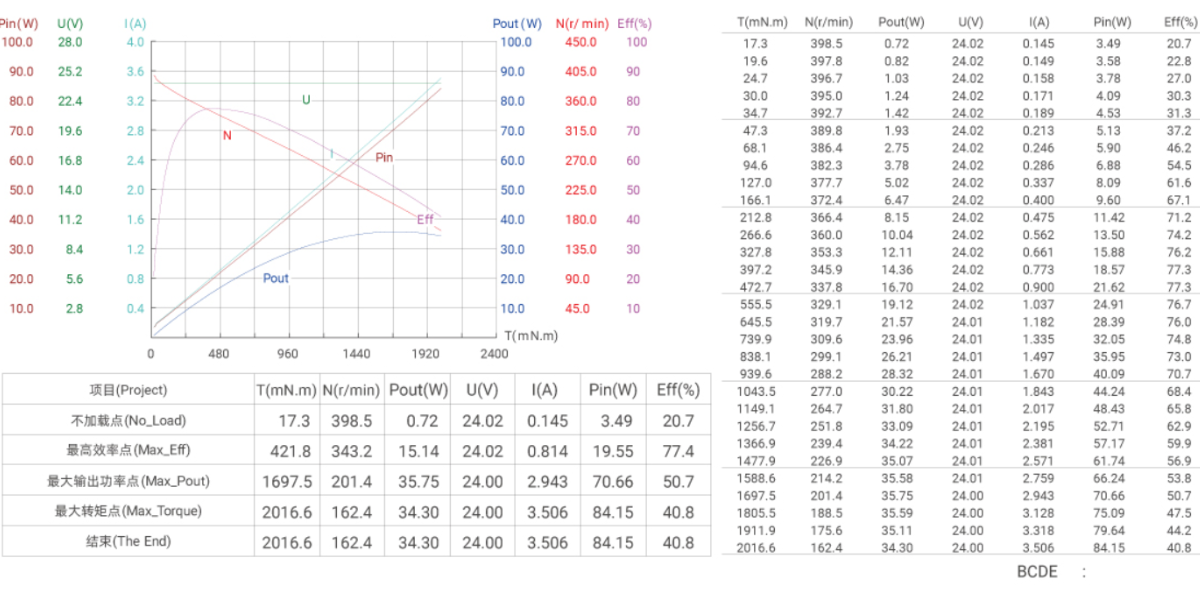

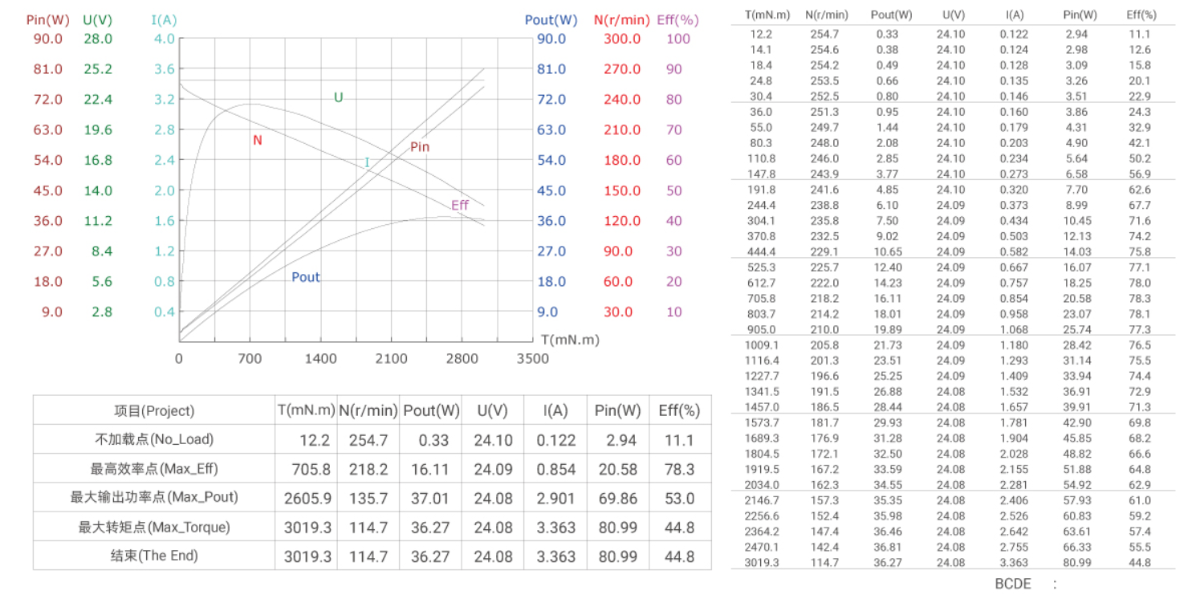

EL-7025

Motor Characteristic Curve

EL-9015

Motor Characteristic Curve

EL-9025

Motor Characteristic Curve

FAQ

Q1: What communication protocols are supported by the EL Series?

A1: The EL Series supports CANBUS and RS485, ensuring compatibility with mainstream control systems.

Q2: Is the EL Series an all-in-one integrated module?

A2: Yes, the EL Series is an all-in-one module integrating the motor, encoder, and reducer for easy installation and space-saving.

Q3: Does the EL Series support a hollow shaft design?

A3: Yes, it features a hollow shaft structure, allowing for cable routing or structural integration.

Q4: What applications are suitable for the EL Series?

A4: The EL Series is suitable for robotic arms, pipeline robots, exoskeletons, AGVs, LiDAR gimbals, and more.

Q5: Can the modules be customized?

A5: Yes, customization is available for specific torque requirements, structural designs, or communication interfaces.

Q6: Is the EL Series flexible in mounting options?

A6: Yes, the EL Series supports various flange mounting options to fit diverse system designs.