Product Description

Cemented carbide stamping die engineered for strength and superior wear resistance, making it ideal for high-speed packaging machinery. Designed to maintain dimensional stability and performance under prolonged use in high-pressure environments, this die supports continuous production cycles while reducing maintenance and downtime. Suitable for demanding industrial applications where precision and durability are critical.

Tungsten steel mold

Wear-resistant and durable

High quality carbide mold series

|

|

|

|

|

|

Non-standard customized alloy molds

Good quality and fast delivery

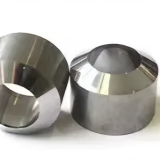

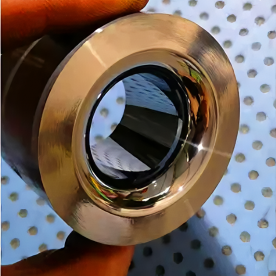

1.Tungsten steel pipe drawing die

Tungsten steel pipe drawing die designed for high-precision metal forming applications, offering exceptional hardness, wear resistance, and dimensional stability. Ideal for drawing metal pipes and tubes with consistent surface finish and tight tolerances, suitable for industrial-scale production environments requiring long service life and high efficiency.

2. Wire drawing die

Wire drawing die engineered for precision wire reduction processes, providing excellent surface finish, consistent diameter control, and extended tool life. Made from high-hardness materials such as tungsten carbide or polycrystalline diamond, this die is ideal for high-speed wire production in industries such as electronics, automotive, and telecommunications, ensuring reliability and accuracy in every run.

3. Tungsten steel extrusion die

Tungsten steel extrusion die designed for high-pressure metal forming applications, offering superior hardness, heat resistance, and wear resistance. Ideal for continuous extrusion of complex profiles with tight dimensional tolerances, this die ensures consistent surface quality and long service life. Suitable for use in the manufacturing of aluminum, copper, and other non-ferrous metal components in industries such as aerospace, automotive, and construction.

4. Tungsten steel cold heading die

Tungsten steel cold heading die designed for high-strength fastener and component production under cold forming conditions. Engineered to withstand extreme pressure and repeated impact without deformation, this die provides excellent wear resistance, dimensional stability, and long service life. Ideal for manufacturing bolts, screws, rivets, and other precision metal parts in automotive, aerospace, and construction industries, where accuracy and durability are critical.

5. Standard parts die

Standard parts die designed for the efficient and repeatable production of commonly used mechanical components. Manufactured with high-strength tool steels or tungsten alloys, the die ensures precision, durability, and compatibility with automated stamping or forming systems. Ideal for producing fasteners, washers, bushings, and other standardized industrial parts used in automotive, electronics, and machinery applications, ensuring consistency in quality and dimensional accuracy across high-volume production.

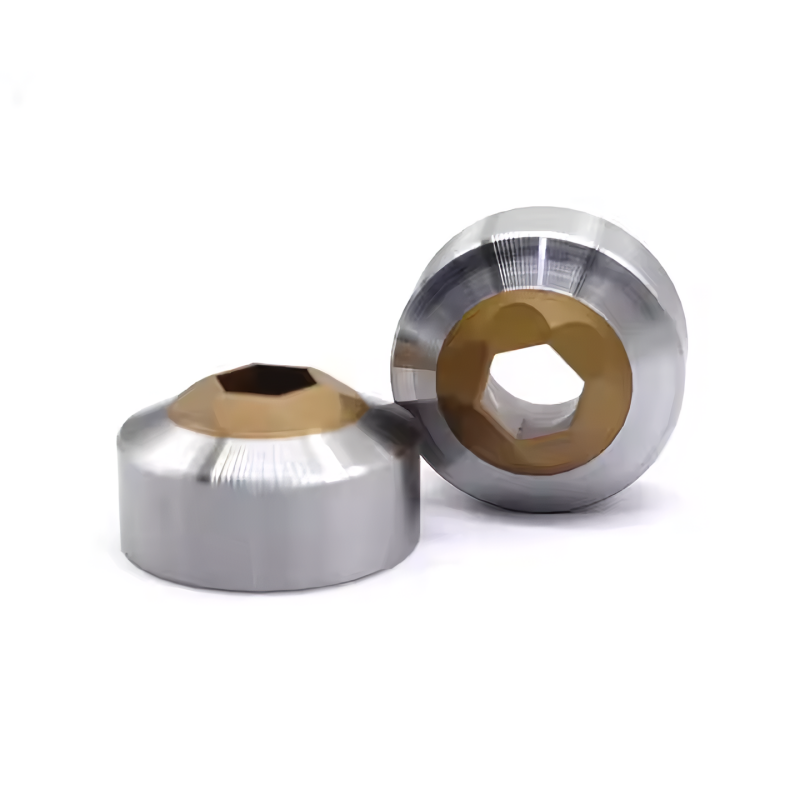

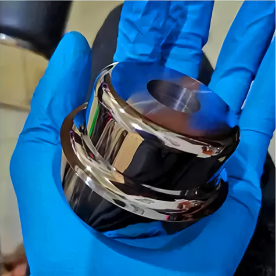

6. Tungsten steel die

Tungsten steel die designed for high-precision forming, stamping, and cutting applications under extreme pressure and wear conditions. With exceptional hardness and thermal resistance, this die ensures extended service life, consistent dimensional accuracy, and superior surface quality, making it ideal for use in high-volume production across the automotive, aerospace, and electronics industries.

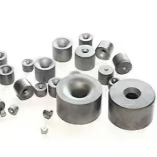

7. Tungsten steel blank

Tungsten steel blank prepared for machining or toolmaking, offering high hardness, excellent wear resistance, and structural integrity. Suitable for producing dies, cutting tools, molds, and mechanical components that require strength and durability in harsh environments. Ideal for precision industries where raw material performance is critical.

8. Tungsten steel roller die

Tungsten steel roller die developed for continuous forming and rolling processes, offering superior strength, resistance to deformation, and wear resistance under high loads. Designed for high-speed production lines in metal forming industries, especially for the fabrication of tubes, profiles, and structural components where smooth surface finish and dimensional consistency are essential.

Made with care, safe to use

This product has carefully selected materials and stable performance. It can be customized according to drawings.

Not easy to corrode, high hardness Aluminum nail body and carbon steel nail core Combined with smooth surface. |

|

Smooth finish, no burrs Aluminum nail body and carbon steel nail core Combined surface is smooth. |

|

Various specifications can be customized Good corrosion resistance when exposed to harsh environments, Environmentally friendly materials, safe to use. |

|

Scope of application: Widely used in water engineering, chemical engineering, electricity, urban construction and other industries

|

|

|

Water supply project | Petrochemical Engineering | Chemical Engineering |

|

|

|

Power Industry | Agricultural irrigation | Urban Construction |

Product parameters

Item | Detail |

Characteristic | Impact-resistant |

Type of Operation | Single-process mold |

Surface Treatment | Chrome plating |

Color | Bright |

Product Name | Alloy molds |

Main Processing Equipment | Lathe |

Applicable Machine Tools | Combination machines |

Thickness | 50 mm |

Type of Process | Powder metallurgy |

Material | Tungsten |

Function | Wear resistance |

Scope of Application | Pressure sintering powder metallurgy mold |

Shipping Method | Logistics |

Quality Grade | Level |