Product Description

Achieve superior precision and performance with our Swiss Type CNC Machining Services, specially tailored for high-quality aluminum components. Our state-of-the-art Swiss CNC machines are ideal for producing complex, tight-tolerance parts with exceptional repeatability, making them the go-to solution for industries such as aerospace, medical, electronics, and automotive.

6061-T6: Excellent all-around alloy with good strength, corrosion resistance, and machinability. Common for structural components, housings, and enclosures. 7075-T6: High-strength aluminum alloy, often used in aerospace and performance-critical applications. |

2024-T3: High fatigue resistance, ideal for aerospace and military components. 5052-H32: Excellent corrosion resistance, especially in marine and chemical environments. |

6063: Often used for architectural and precision applications due to its superior surface finish. 5083: Known for excellent performance in marine and cryogenic applications. |

Functional Features

| High Precision | Capable of holding tight tolerances down to ±0.005 mm, ideal for intricate and miniature aluminum parts. |

| Exceptional Surface Finish | Achieve smooth surface finishes that often require little to no post-processing. |

| Efficient for Small to Medium Parts | Designed for small-diameter workpieces, especially long and slender parts. |

| Multi-Axis Capability | Complex geometries can be machined in one setup, reducing time and cost. |

| Fast Turnaround | Optimized for high-speed, high-volume production without compromising quality |

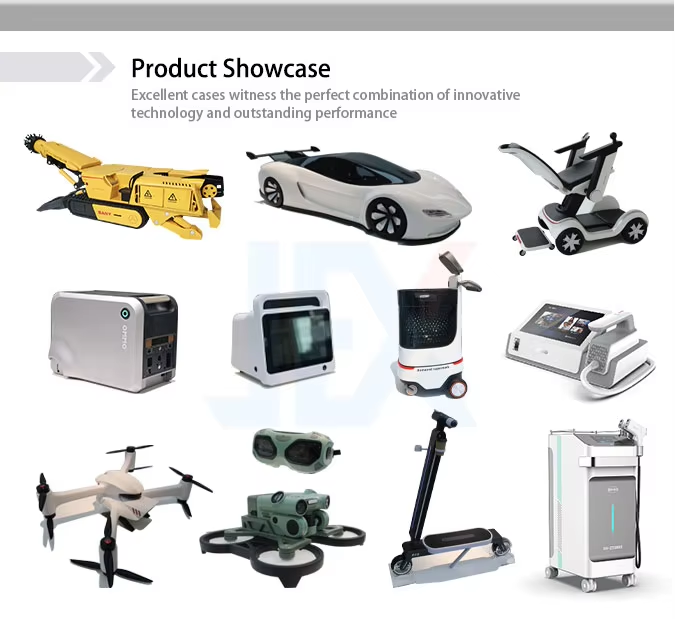

Product Display

Application

Medical device components |

Aerospace fittings and housings |

Electronic connectors and enclosures |

Precision automotive part |

Product parameters

| Parameter | Specification |

| Material | Aluminum alloys: 6061, 7075, 2024, 5052, 6063, 5083, MIC-6, custom alloys |

| Max. Part Diameter | Ø 2 mm – 32 mm (up to 38 mm on request) |

| Max. Part Length | Up to 600 mm (depending on part geometry) |

| Tolerance Accuracy | ±0.005 mm (±5 microns), tighter upon request |

| Surface Finish | Ra 0.4 µm or better (machined finish); post-processing optional |

| Machining Axes | Up to 7-axis simultaneous machining |

| Production Volume | Prototype to high-volume (1–1,000,000+ pcs) |

| Threading | Internal & external (metric, UNC, UNF, custom) |

| Hole Diameter Range | Ø 0.3 mm – Ø 25 mm (depending on setup) |

Application wiring diagram

Custom Process

Contact

Negotiation

Production

Transportation

Quality Control

We follow a rigorous quality control process to ensure that every aluminum part we machine meets or exceeds customer specifications. From incoming material verification to final inspection, our QC system is designed for zero-defect delivery.

| QC Item | Details |

| Certifications | ISO 9001:2015 / ISO 13485 (if applicable) |

| Inspection Equipment | CMM (Coordinate Measuring Machine), Vision Systems, Micrometers, Calipers |

| First Article Inspection (FAI) | Available upon request with full dimensional report |

| In-Process Inspection | Continuous inspection during production using SPC (Statistical Process Control) |

| Final Inspection | 100% critical dimension check before packaging |

| Material Certification | Available for all aluminum grades (with traceability) |

| Surface Finish Verification | Ra surface roughness testers; visual & tactile inspection |

| Documentation | Full QC reports, CoC (Certificate of Conformance), RoHS compliance (if needed) |

| Tolerance Verification | Measured to ±0.005 mm or better, depending on part requirement |

Service

FAQ

1. What is Swiss Type CNC machining, and how is it different from conventional CNC turning?

Swiss Type CNC machining is ideal for producing small, high-precision parts. Unlike conventional CNC lathes, Swiss machines support the material very close to the cutting tool, reducing deflection and increasing accuracy—especially for long and slender components.

2. What aluminum alloys do you work with?

We commonly machine:

6061-T6

7075-T6

2024-T3

5052-H32

5083

6063

MIC-6 (cast plate)

Custom aluminum alloys can also be accommodated upon request.

3. What tolerances can you achieve?

We regularly achieve tolerances of ±0.005 mm (5 microns) or tighter, depending on part geometry and material. Tighter tolerances can be discussed based on specific needs.

4. What is your typical lead time?

Prototypes: 3–7 business days

Small to medium runs: 1–2 weeks

High-volume orders: 2–4 weeks (depending on complexity and order size)

Expedited services are available.

5. Do you offer secondary processes like anodizing or assembly?

Yes, we offer a range of secondary services including:

Anodizing (clear, black, color)

Bead blasting, polishing

Laser marking

Assembly and packaging

Let us know your finishing and post-processing requirements.