Product Description

Description

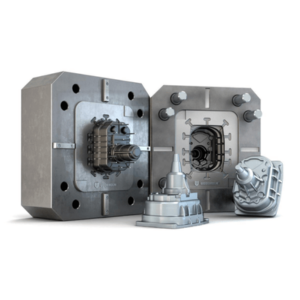

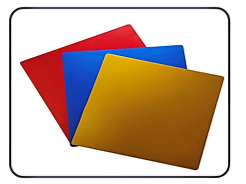

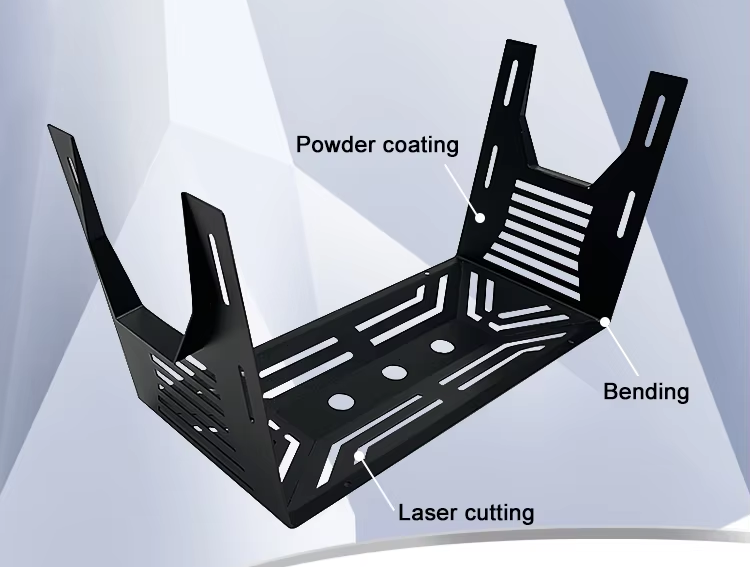

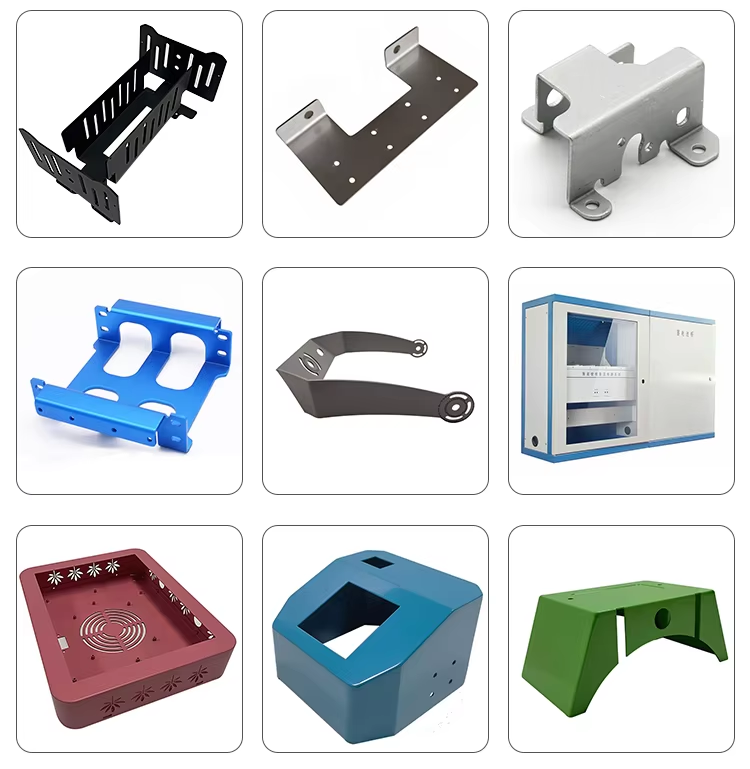

Produce custom sheet metal parts based on customer designs using high-precision laser cutting and metal stamping processes. Capable of handling a wide range of materials such as aluminum, stainless steel, and carbon steel. Certified with ISO 9001, ensuring consistent quality, dimensional accuracy, and reliability. Ideal for applications across various industries including automotive, electronics, and machinery, supporting both prototyping and mass production with fast turnaround times.

OEM CNC SHEET METAL

BENDING FABRICATION

QUALITY ASSURANCE | PROFESSIONAL SERVICES | PREFERENTIAL PRICE | FAST PROCESSING |

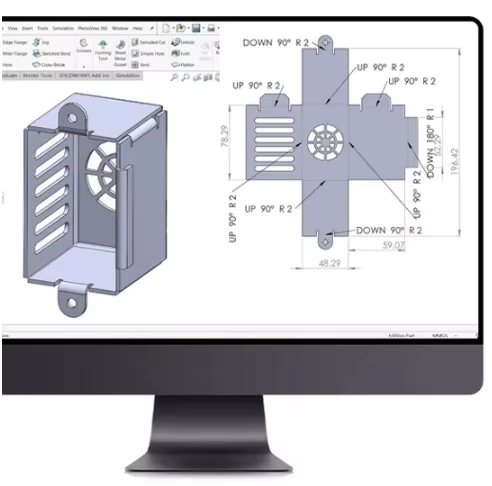

PROFESSIONAL

TECHNICAL SUPPORT

SUPPORTED SOFTWARE TYPES

SHEET METAL BENDING FABRICATION

FLOW CHART

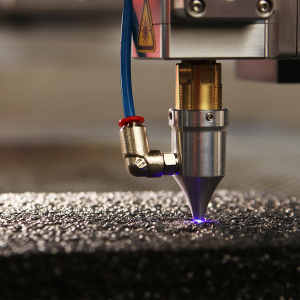

1. MATERIAL CUTTING |

|

2. MACHINED PROCESS |

|

3. AUXILIARY PROCESS |

|

4. SURFACE TREATMENT |

|

5. ASSEMBLY |

|

SURFACE TREATMENT

|

|

|

Large Painting Workshop | Large Baking Workshop | Powder Spraying |

|

|

|

Anodized | Radium Carving | Silk Screen Printing |

Application

| Automotive Industry |

| Home Appliance Industry |

| Electronics Industry |

| Interior Design |

| Construction Industry |

| Machinery Industry |

| Energy Industry |

One-stop service

|

|

|

|

|

Laser Cutting | Stamping | Bending | Welding | Surface Treatment |

Product parameters

Designing | According to customers' drawings and samples. |

Materials | Steel, Stainless steel, Copper, Brass, Aluminum, Zinc alloy. |

Surface Finish | Electric plating,Sand blasting,Powder coating, Lacquer, Paiting, Oxidization. |

Process Flow | Stamping:shearing-blanking-punching-bending-stretching-turning up edging- trimming-molding |

Spraying: alkaline degreasing-water scrubbing-acid pickling-waterscrubbing-electrolytic- | |

degreasing-surface-conditioning-phosphate-spraying- baking-checking-packing | |

Plating:alkaline degreasing-water scrubbing-acid pickling-water scrubbing- electrolytic- | |

degreasing-neutralization-plating-water-urubbing- passivating- sealing course-baking | |

Testing | At least 72 hours salt spray test; Thickness of plating or coating |

Custom Process

Consult customer service

Confirm drawings

Online quotation

Confirm order

Five-star praise

Confirm receipt

Packaging and delivery

Processing and produetion