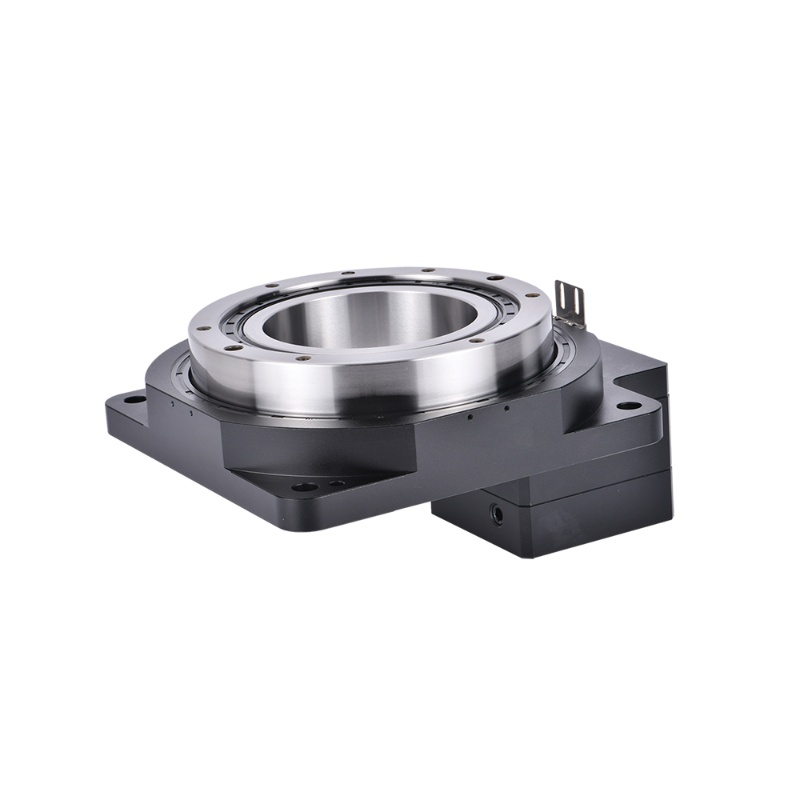

Product Description

YH series central control rotary platform is used in various rotary motion occasions. It can replace DD MOTOR and cam divider. It combines high working efficiency, high precision, high rigidity and high cost performance. It is a revolutionary product in rotary motion mechanism. It strikes a balance between the two, with repeated positioning accuracy of ≤ 5 seconds. The motor is easy to configure and has a stable load. It can be matched with AC servo motor or stepper motor to split at any angle. It can meet the digital control that the divider cannot achieve, and the positioning accuracy is comparable to that of DD motor.

The ring-enveloping roller structure is simple

High precision

Smoothness

High speed

The ring-enveloping roller structure is simple

This structure uses cam input and shaft output to provide any remote motion.

High precision

The roller and cam are matched without clearance, which can maintain high segmentation accuracy and high torque, ensuring the ability to bear heavy loads.

Smoothness

Since the output shaft is designed to rotate continuously at any position, the transmission device is smooth with minimal vibration and noise.

High speed

The preload is applied to the precision-machined roller and cam dimensional support ribs to completely avoid the generation of gaps, so that the turntable runs smoothly and at high speed. The fully controlled acceleration can reduce the impact caused by load or vibration.

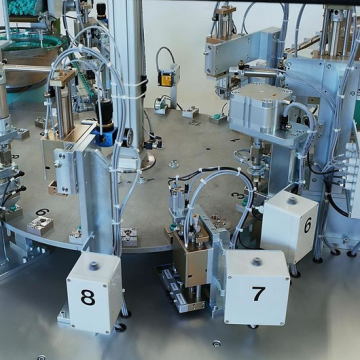

Application

Hollow rotary platforms are widely used in automation equipment, robots and precision manufacturing. They provide high-precision rotary motion in robot arm joints to achieve flexible grasping and positioning; they are used in automated indexing plates to complete precision indexing and multi-station processing; they support lens rotation scanning in optical inspection equipment to ensure high-resolution imaging; and they are equipped with vacuum suction cups in semiconductor equipment to achieve high-speed wafer transmission and positioning. The central through-hole design facilitates the integration of cables and air circuits, reduces entanglement, and improves the compactness of the equipment. It is suitable for scenarios that require 360° continuous rotation, high load and precise angle control, such as CNC machine tools, laser processing and automated assembly lines.

Product parameters

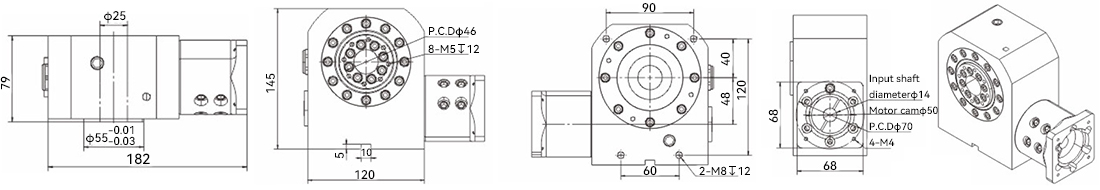

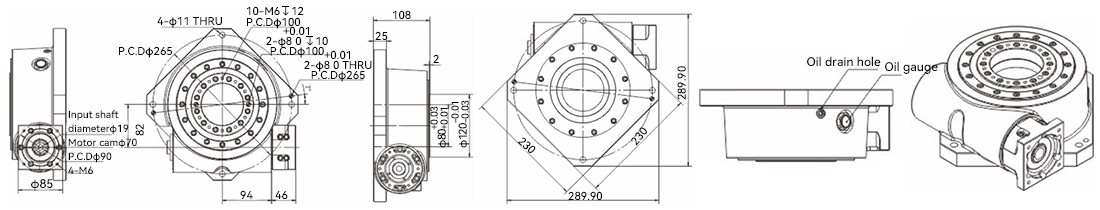

YH48HP-15K

Rotating platform bearing | Crossed roller bearings | Applicable motor | 60 frame servo |

Reduction ratio i | 1:15 (Without reducer) | Center height mm | 90 |

Radial load kgf | 30 | Motor w | 400 |

Working disc diameter mm | Φ55 | Center hole diameter mm | Φ25 |

Minimum split angle deg | 0.001 | Division accuracy sec | ±25 |

Repeat positioning accuracy arc - sec | 8 | Precision life hr | 20000 (intermittent operation) |

Note: The recommended maximum diameter of the rotating tooling plate is 400mm and the load-bearing capacity is 30kg | |||

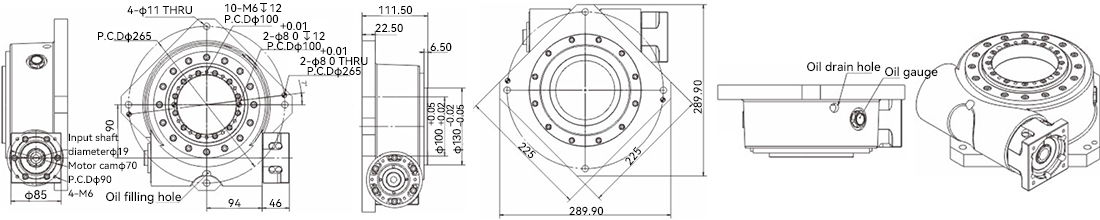

YH68HP-20K

Rotating platform bearing | Crossed roller bearings | Applicable motor | 60 frame servo |

Reduction ratio i | 1:20(Without reducer) | Motor type | Planetary reducer + servo motor |

Tipping moment N.m | 400 | Allowable inertia moment load N.m | 75 |

Allowable input torque N.m | ≤30 | Parallelism of rotating platform mm | 0.02 |

Allowable input speed r/min | <1000 | Concentricity of rotating platform mm | 0.02 |

Repeatable positioning accuracy arc-sec | ±15 | Precision life hr | 20000 (intermittent operation) |

Positioning accuracy arc-sec | ±30 | Protection level IP | 40 |

Note: The recommended maximum diameter of the rotating tooling plate is 500mm and the load-bearing capacity is 80kg | |||

YH82HP-24K

Rotating platform bearing | Crossed roller bearings | Applicable motor | 80 frame servo |

Reduction ratio i | 1:24(Without reducer) | Motor type | Planetary reducer + servo motor |

Tipping moment N.m | 584 | Allowable inertia moment load N.m | 800 |

Allowable input torque N.m | ≤68 | Parallelism of rotating platform mm | 0.02 |

Allowable input speed r/min | <1000 | Concentricity of rotating platform mm | 0.02 |

Repeatable positioning accuracy arc-sec | ±15 | Precision life hr | 20000 (intermittent operation) |

Positioning accuracy arc-sec | ±30 | Protection level IP | 40 |

Note: The recommended maximum diameter of the rotating tooling plate is 600mm and the load-bearing capacity is 200kg | |||

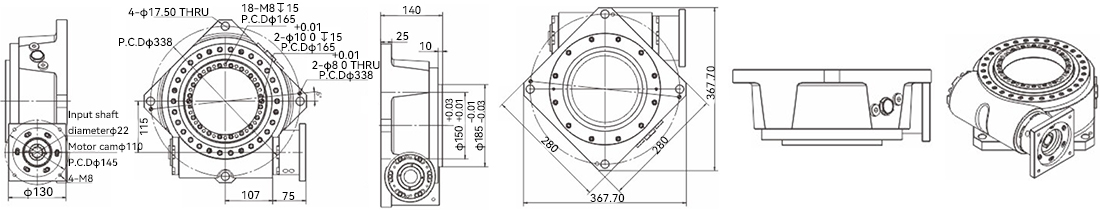

YH90HP-20K

Rotating platform bearing | Crossed roller bearings | Applicable motor | 80 frame servo |

Reduction ratio i | 1:20(Without reducer) | Motor type | Planetary reducer + servo motor |

Tipping moment N.m | 625 | Allowable inertia moment load N.m | 220 |

Allowable input torque N.m | ≤72 | Parallelism of rotating platform mm | 0.02 |

Allowable input speed r/min | <1000 | Concentricity of rotating platform mm | 0.02 |

Repeatable positioning accuracy arc-sec | ±15 | Precision life hr | 20000 (intermittent operation) |

Positioning accuracy arc-sec | ±30 | Protection level IP | 40 |

Note: The recommended maximum diameter of the rotating tooling plate is 600mm and the load-bearing capacity is 260kg | |||

YH115HP-20K

Rotating platform bearing | Crossed roller bearings | Applicable motor | 130 frame servo |

Reduction ratio i | 1:20(Without reducer) | Motor type | Planetary reducer + servo motor |

Tipping moment N.m | 1028 | Allowable inertia moment load N.m | 250 |

Allowable input torque N.m | ≤90 | Parallelism of rotating platform mm | 0.02 |

Allowable input speed r/min | <1000 | Concentricity of rotating platform mm | 0.02 |

Repeatable positioning accuracy arc-sec | ±15 | Precision life hr | 20000 (intermittent operation) |

Positioning accuracy arc-sec | ±30 | Protection level IP | 40 |

Note: The recommended maximum diameter of the rotating tooling plate is 800mm and the load-bearing capacity is 500kg | |||

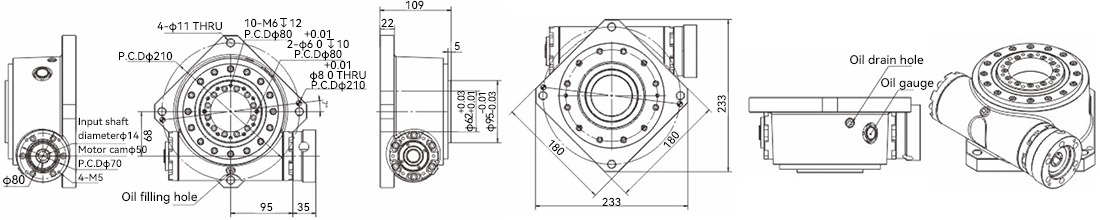

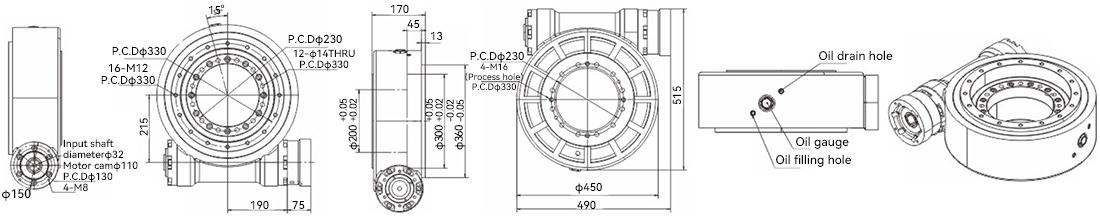

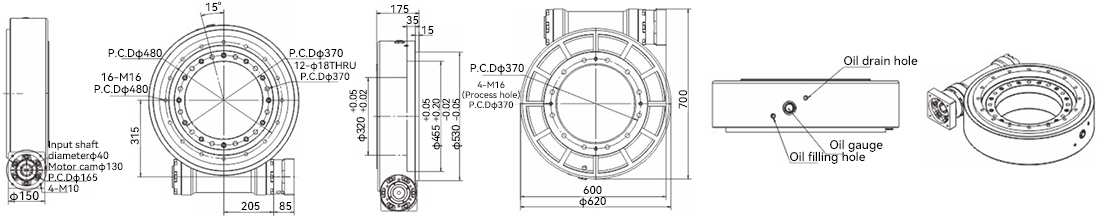

YH215HP-40K

Rotating platform bearing | Crossed roller bearings | Applicable motor | 130 frame servo |

Reduction ratio i | 1:40(Without reducer) | Motor type | Planetary reducer + servo motor |

Tipping moment N.m | 3749 | Allowable inertia moment load N.m | 18000 |

Radial load T | 1.9 | Parallelism of rotating platform mm | 0.02 |

Allowable input speed r/min | <800 | Concentricity of rotating platform mm | 0.02 |

Repeatable positioning accuracy arc-sec | ±15 | Precision life hr | 20000 (intermittent operation) |

Positioning accuracy arc-sec | ±30 | Protection level IP | 40 |

Note: The recommended maximum diameter of the rotating tooling plate is 1300mm and the load-bearing capacity is 1500kg | |||

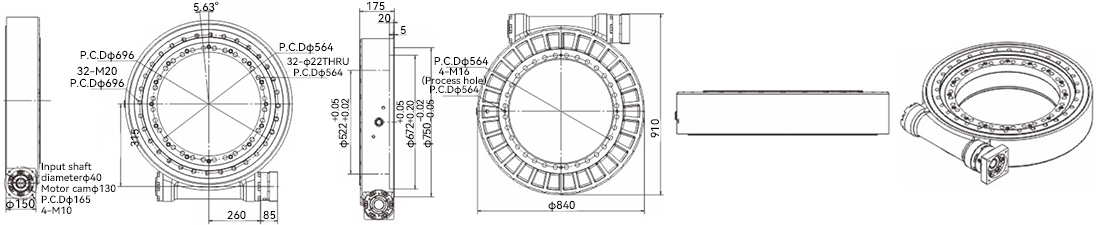

YH315HP-60K

Rotating platform bearing | Crossed roller bearings | Applicable motor | 180 frame servo |

Reduction ratio i | 1:60(Without reducer) | Motor type | Planetary reducer + servo motor |

Tipping moment N.m | 13354 | Allowable inertia moment load N.m | 28000 |

Radial load T | 2.5 | Parallelism of rotating platform mm | 0.03 |

Allowable input speed r/min | <800 | Concentricity of rotating platform mm | 0.03 |

Repeatable positioning accuracy arc-sec | ±15 | Precision life hr | 20000 (intermittent operation) |

Positioning accuracy arc-sec | ±30 | Protection level IP | 40 |

Note: The recommended maximum diameter of the rotating tooling plate is 1400mm and the load-bearing capacity is 2500kg | |||

YH415HP-60K

Rotating platform bearing | Crossed roller bearings | Applicable motor | 180 frame servo |

Reduction ratio i | 1:60(Without reducer) | Motor type | Planetary reducer + servo motor |

Tipping moment N.m | 30000 | Allowable inertia moment load N.m | 60000 |

Radial load T | 4.5 | Parallelism of rotating platform mm | 0.03 |

Allowable input speed r/min | <800 | Concentricity of rotating platform mm | 0.03 |

Repeatable positioning accuracy arc-sec | ±15 | Precision life hr | 20000 (intermittent operation) |

Positioning accuracy arc-sec | ±30 | Protection level IP | 40 |

Note: The recommended maximum diameter of the rotating tooling plate is 1300mm and the load-bearing capacity is 1500kg | |||

Service

Direct connection can improve reliability and reduce costs. The workbench and robot arm that need to be installed can be directly installed on the rotating platform. Compared with the use of mechanical parts such as pulleys, the time and cost of mechanical design, parts allocation, belt state adjustment and other links can be reduced.

Motor configuration

You can freely choose stepper motors or servo motors of various brands, except for the KTN series dedicated stepper motors.

High-precision positioning without backlash

No backlash, positioning accuracy ≤15sec, repeat positioning accuracy can reach ±5sec.

Large-diameter hollow structure

Wiring and piping are more convenient and simple, and the advantages of this feature are particularly prominent in wiring and piping environments with complex wiring.

Pack