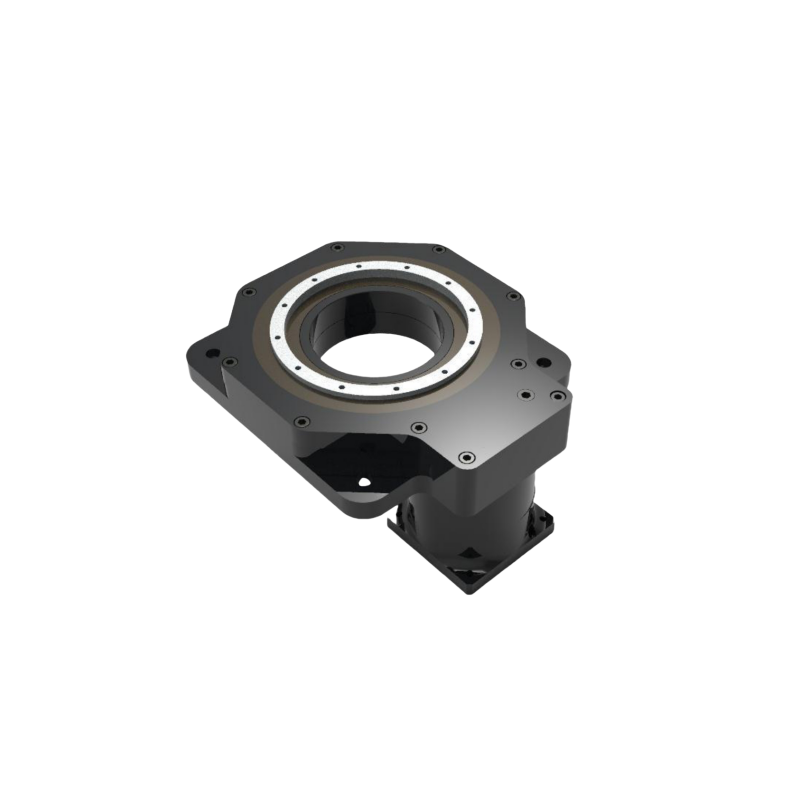

Product Description

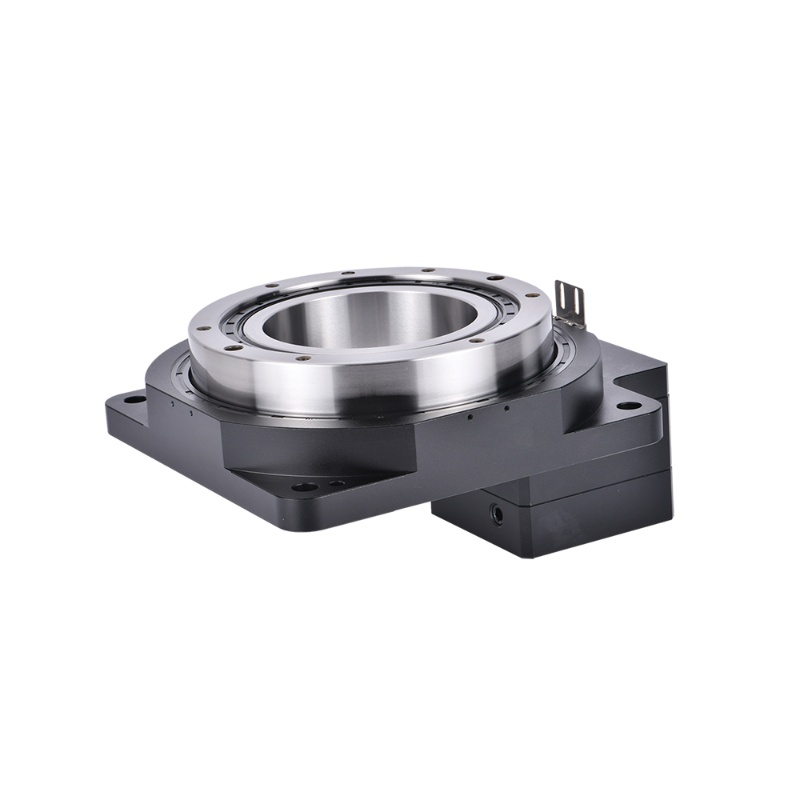

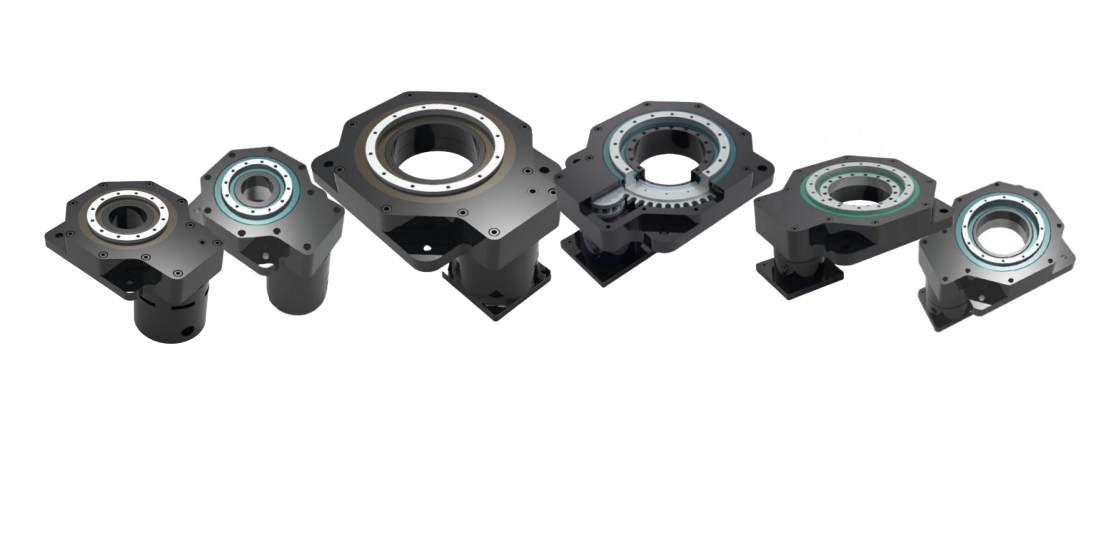

Hollow rotary platform reducer is an automation device that has only become popular in recent years. It is also called: hollow rotary table, hollow rotary platform reducer, high-precision hollow spiral platform reducer, stepping rotary platform, servo rotary table, planetary rotary table, rotator and steering gear, etc. Because it has the characteristics of cam divider and DD motor, and is smaller than the former two, it has been sought after and used in recent years. It combines high precision and high efficiency, becoming a perfect substitute for traditional cam dividers and DD motors.

Can be used with 100~750W servo motors

Workpieces can be directly locked

The rotating disk can directly lock the workpiece, improving the convenience of workpiece loading

Easy to wire, this rotating platform is hollow design, convenient for wiring and piping

High precision, positioning accuracy is less than one minute, and repeated positioning accuracy can reach ±15sec

Smooth operation, the disk runs smoothly and smoothly, and positioning is fast

Applicable to various motors, the hollow rotating platform can be driven by servo and motor

Application

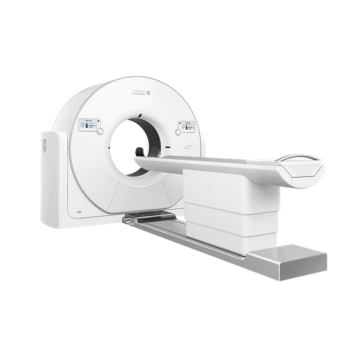

With the advantages of high precision, high rigidity and digital control, the hollow rotary platform can be widely used in the field of automation, directly replacing traditional cam dividers and DD motors. Its core features include hollow structure design (for easy pipeline integration), high positioning accuracy within ±30 arc seconds, direct drive technology to eliminate backlash, and support for multi-station indexing control. Typical application scenarios include semiconductor equipment wafer cutting positioning, multi-angle processing of precision assembly lines, rotating axes of LCD panel handling robotic arms, precise indexing of medical instrument rotary tables, and precise material transfer of packaging machinery. By integrating servo motors and high-resolution encoders, the platform can achieve 0.001° micro-step control to meet high-speed and high-repeat positioning requirements, while simplifying the mechanical structure and reducing maintenance costs. It is particularly suitable for upgrading automation equipment with limited space.

CT/MRI rotating parts

Wafer handling robot

Centrifuge

Product parameters

Parameters | GU66 | GU100 | GU146 |

Rotating platform bearing | Crossed roller bearings | ||

Reduction ratio i | 1:5 | ||

Allowable input torque N.m | ≤50 | ≤120 | ≤180 |

Allowable disk speed rpm | 150 | 150 | 75 |

Repeatable positioning accuracy arc-sec | ±15 | ±15 | ±15 |

Positioning accuracy arc-sec | ±30 | ±30 | ±30 |

Applicable motor | planet+60 frame servo | planet+80 frame servo | planet+130 frame servo |

Allowable axial pressure N | 1000 | 2000 | 4000 |

Rotating platform flatness mm | 0.02 | ||

Rotating platform concentricity mm | 0.01 | ||

Precision life hr | 20000(intermittent operation) | ||

Protection level IP | 50 | ||

Service

1. Fast delivery of standard products: conventional models are in stock, tested before shipment, and shipped within 5 working days.

2. Logistics progress tracking: After shipment, the waybill number and real-time logistics information are provided, and flexible transportation methods such as air/land transportation are supported.

3. Installation, commissioning and calibration: Provide professional installation guidance to ensure that the equipment reaches the best operating state and meets the requirements of repeated positioning within ±5 arc seconds.

4. Maintenance and fault diagnosis: Provide regular maintenance recommendations, wear parts replacement and remote troubleshooting services to extend equipment life and ensure long-term stable operation.

5. Automation system integration: Support collaborative integration with robots, PLCs, and motion controllers, provide software and hardware interface development and multi-axis linkage control solutions, and realize intelligent production line upgrades.

Pack