Product Description

Automated forklifts are available from several of today’s top forklift manufacturers. However, not all forklift manufacturers are in the business of developing automated forklifts, and as a result, miss out on AGV market expansion. Is your business one of them?

Manufacturers of manually operated forklifts may worry that they will cut into their own profits by selling automated forklifts. But what they don’t realise is that not including autonomous vehicles in their product offerings will cause them to ultimately fall behind competitively once more customers transition to automated forklifts in the future.

Here, we have put together five critical reasons why your business should act immediately and invest in forklifts that are fitted with automated navigation technology.

Product Features

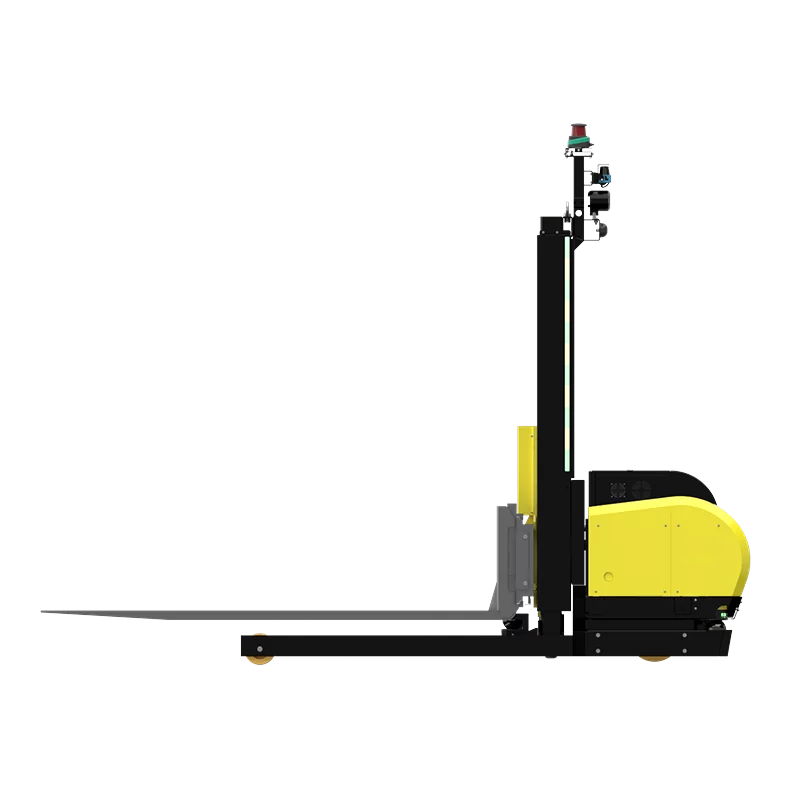

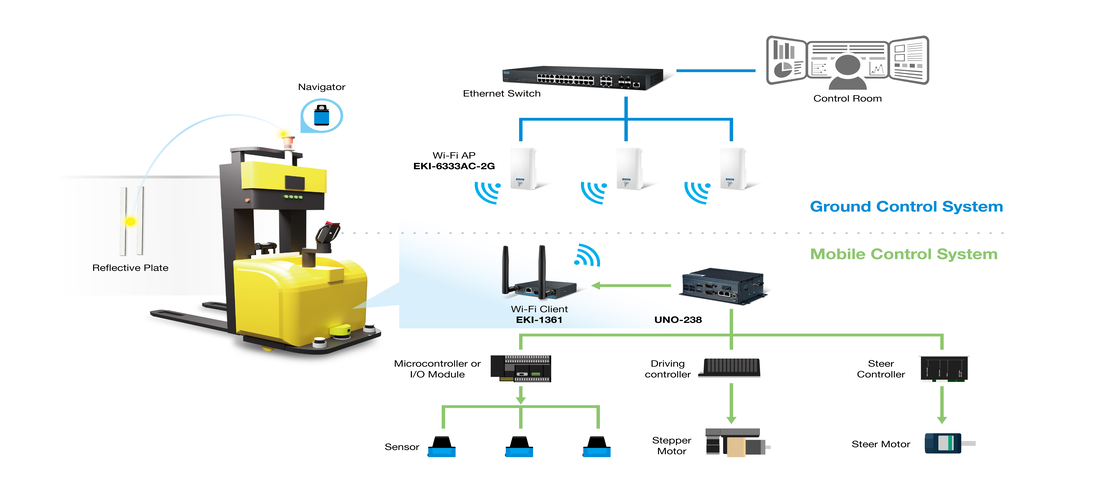

Natural Navigation

The DFR-100 uses advanced natural navigation technology, allowing it to operate without the need for infrastructure changes like magnetic strips or reflectors. This enables seamless integration into existing warehouse layouts, significantly reducing setup time and costs.

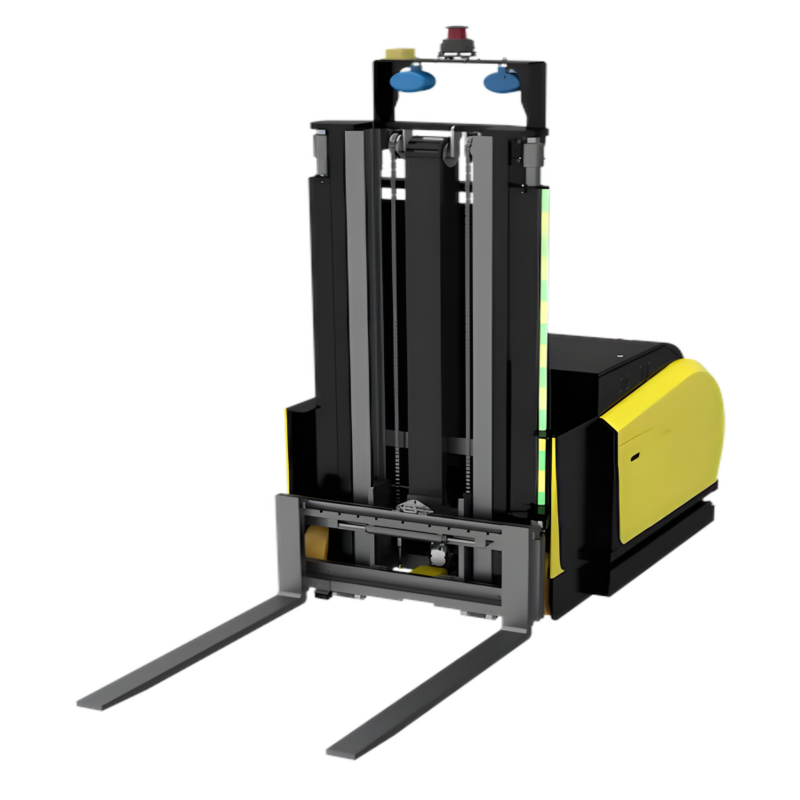

360° Safety Protection

Equipped with 360° safety protection, the DFR-100 ensures maximum safety for nearby workers and equipment. Its comprehensive sensor system continuously monitors the environment, detecting obstacles and adjusting its movements in real time to prevent accidents.

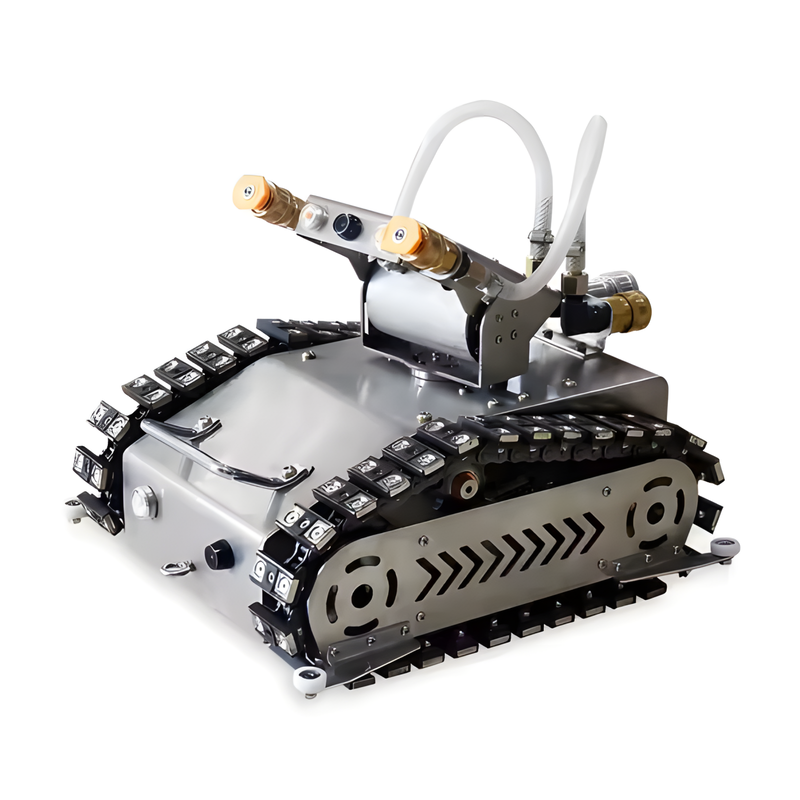

Structure Diagram

Product parameters

| Parameter | Specification |

| Payload Capacity | Up to 2000 kg |

| Navigation Type | Natural Navigation (No infrastructure required) |

| Maximum Speed | Up to 2 m/s |

| Battery Life | Up to 10 hours per full charge |

| Charging Time | 2 hours (0–100%) |

| Safety System | 360° Safety Protection (LIDAR, sensors) |

| Application Type | Mid- to long-distance pallet transport |

| Operation Mode | Autonomous / Semi-autonomous |

| Scalability | Readily extendible fleet integration |

Customer Case

Automotive Parts Manufacturer

Challenge:

Manual forklifts caused delays in delivering parts to the assembly line, leading to bottlenecks and increased labor costs.

Solution:

The manufacturer deployed 4 DFR-100 units in their logistics chain to automate parts delivery across the facility.

Result:

25% faster part delivery to assembly stations

Labor costs reduced by 30%

24/7 operation with minimal human intervention

ROI achieved in 10 months

Third-Party Logistics (3PL) Warehouse

Challenge:

High volume of inbound and outbound pallets required constant forklift movement, causing inefficiencies and errors during peak hours.

Solution:

DFR-100 forklifts were integrated with the warehouse management system (WMS) for autonomous routing and task scheduling.

Result:

40% increase in pallet handling efficiency

Error rate in pallet placement reduced by 90%

Streamlined workflow across three shifts

Scalable fleet model allowed easy expansion from 3 to 7 vehicles

Cold Storage Facility

Challenge:

Harsh temperatures (-20°C) made manual forklift operation uncomfortable and unsafe for staff, with high turnover and frequent downtimes.

Solution:

3 DFR-100 units with cold-resistant modifications were deployed to handle pallet movements in freezing conditions.

Result:

Continuous operation in sub-zero environments

Reduced worker exposure to cold by 80%

35% improvement in pallet turnaround time

Significant boost in safety and employee satisfaction

Company Information

Company Details

FAQ

| Question | Answer |

| What is the DFR-100 and who is it for? | The DFR-100 is an autonomous forklift designed for mid- to long-distance pallet transport. It's ideal for manufacturers, logistics companies, cold storage facilities, and any operation looking to reduce labor costs and increase material handling efficiency |

| How does the DFR-100 navigate? | The DFR-100 uses Natural Navigation technology, allowing it to operate without physical infrastructure like reflectors, magnetic tape, or markers. It maps and adapts to its environment using onboard sensors and LIDAR, enabling easy integration into existing warehouse layouts. |

| What safety features does the DFR-100 have? | The DFR-100 features 360° Safety Protection, including LIDAR and environmental sensors that continuously scan for obstacles. It automatically adjusts its movements in real time to prevent collisions, ensuring worker and equipment safety. |

| Is the DFR-100 scalable for larger fleets? | Absolutely. The DFR-100 is built for scalable deployment, allowing businesses to start with a few units and easily expand their fleet as operational demands grow. It also integrates seamlessly with warehouse management systems (WMS) for coordinated fleet operation. |

| Can it operate autonomously or does it require human intervention? | The DFR-100 operates in autonomous and semi-autonomous modes. While it is designed for fully autonomous operation, manual override or supervision is possible when needed. |