Product Description

As industries push for higher efficiency, scalability, and safety in material handling, the DFR-200 leads the way as the next-generation autonomous forklift built for heavy-duty, high-throughput environments. Designed with advanced AI-driven navigation and smart load optimization, the DFR-200 offers significant improvements in payload capacity, speed, and intelligent fleet coordination.

Product Features

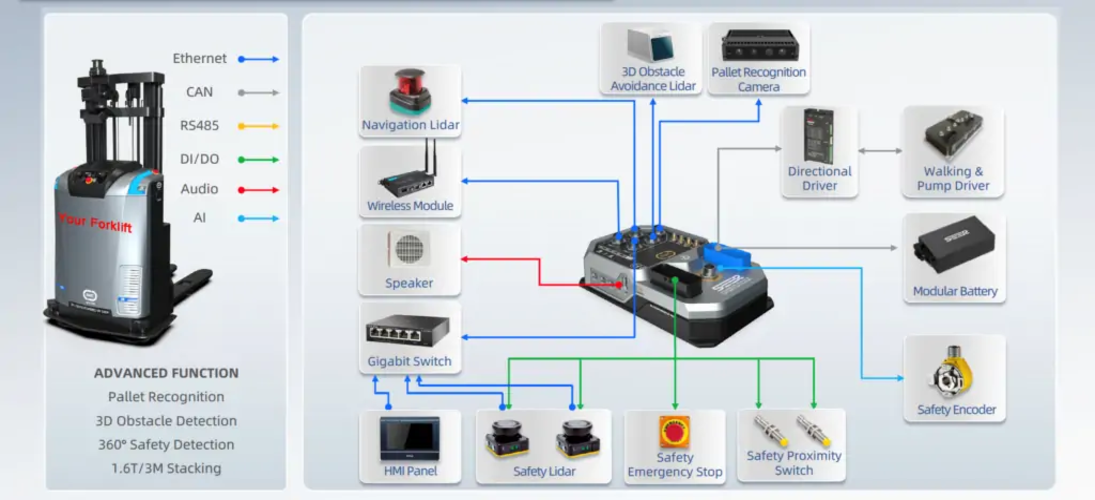

AI-Enhanced Natural Navigation

Building on the foundation of the DFR-100’s natural navigation, the DFR-200 incorporates AI-enhanced SLAM (Simultaneous Localization and Mapping) technology. This allows it to dynamically optimize routes, identify traffic patterns, and avoid congested zones — improving travel time and task efficiency in real time.

Smart Load Management

The DFR-200 includes intelligent load sensing and auto-balancing systems. It detects uneven loads, automatically adjusts speed and acceleration, and issues alerts if load integrity is at risk, ensuring safe and stable transport every time.

Advanced Multi-Vehicle Coordination

With built-in V2V (Vehicle-to-Vehicle) communication, the DFR-200 supports synchronized operation with other autonomous units, enabling real-time task distribution and dynamic rerouting across large fleets and multi-zone facilities.

Adaptive Environment Tolerance

Enhanced environmental sealing and thermal control systems make the DFR-200 suitable for a wider range of operational environments, including dusty warehouses, damp loading docks, and sub-zero cold storage.

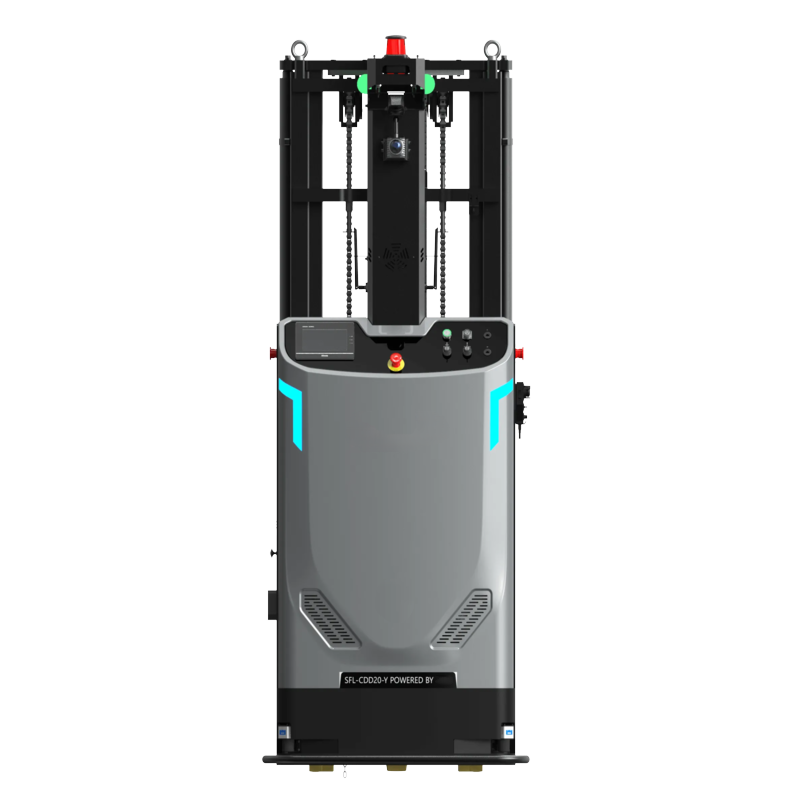

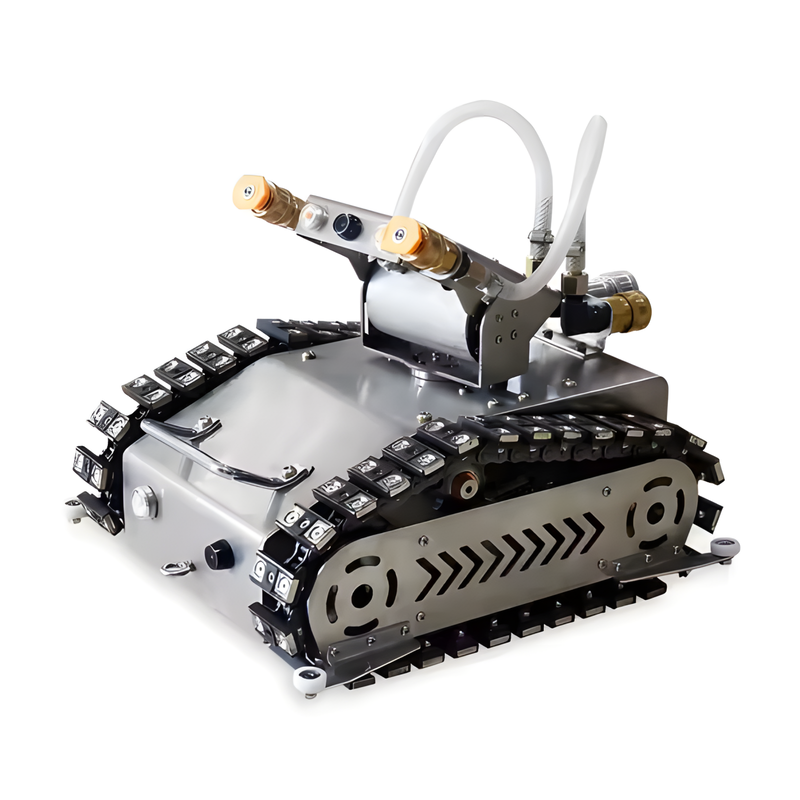

Structure Diagram

Product parameters

| Parameter | Specification |

| Payload Capacity | Up to 3000 kg |

| Navigation Type | AI-Enhanced Natural Navigation (No infrastructure) |

| Maximum Speed | Up to 2.5 m/s |

| Battery Life | Up to 12 hours per full charge |

| Charging Time | 2 hours (0–100%) or 80% charge in 45 minutes (fast charge) |

| Safety System | 360° Safety + Smart Load Protection (AI + LIDAR + Ultrasonics) |

| Application Type | Heavy-load transport, multi-zone operations |

| Operation Mode | Autonomous / Semi-autonomous |

| Fleet Coordination | Real-time V2V Communication, WMS & ERP integration |

Customer Case

Automotive Mega-Plant

Challenge:

Massive volumes of parts and heavy components were transported using manual forklifts across multiple production halls, leading to high injury risks and inconsistent delivery timing.

Solution:

Deployment of 10 DFR-200 units across the facility to automate high-capacity transport between storage and production zones.

Result:

50% increase in heavy-part delivery efficiency

Zero incidents related to load imbalances or collisions

Real-time production line sync with ERP and WMS systems

ROI achieved in just 8 months

High-Throughput E-Commerce Fulfillment Center

Challenge:

A large-scale e-commerce company faced operational slowdowns during peak order periods. Manual forklifts were unable to keep up with the volume of pallet transfers between inbound receiving, storage zones, and outbound sorting, leading to delays, increased labor costs, and misrouted pallets.

Solution:

The company integrated 8 DFR-200 forklifts into its fulfillment workflow. The forklifts were synced with the warehouse management system (WMS) and order-picking software, enabling real-time autonomous routing of high-priority shipments.

Result:

60% increase in pallet movement speed during peak hours

99% accuracy in pallet placement and routing

Automated priority handling for express and time-sensitive orders

20% reduction in overtime labor costs

Flexible fleet scaling allowed the addition of 4 more DFR-200 units during seasonal demand spikes

Company Information

Company Details

Coody Robotics is an unfunded company based in Singapore (Singapore), founded in 2019. It operates as a Provider of service robots. Coody Robotics has not raised any funding yet. The company has 445 active competitors, including 113 funded and 29 that have exited.

FAQ

1. What distinguishes the DFR-200 from the DFR-100?

The DFR-200 offers 50% more payload capacity, faster maximum speed, and longer battery life. It also features AI-enhanced natural navigation, smart load management, and V2V (Vehicle-to-Vehicle) communication for fleet coordination — making it ideal for high-throughput, heavy-duty environments.

2. What kind of loads can the DFR-200 handle?

The DFR-200 can carry loads of up to 3000 kg, making it suitable for transporting large and heavy items such as automotive parts, industrial components, and high-density pallet stacks.

3. Can the DFR-200 coordinate with other forklifts or automation systems?

Yes. The DFR-200 supports real-time communication with other autonomous vehicles and integrates seamlessly with Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems for synchronized task management.

4. What navigation technology does it use?

The DFR-200 utilizes AI-enhanced SLAM (Simultaneous Localization and Mapping) as part of its natural navigation system. This allows it to intelligently map and adapt to dynamic environments without requiring any physical infrastructure like magnetic strips or QR markers.

5. How long does the battery last and how is it charged?

Battery Life: Up to 12 hours of operation per full charge

Charging Time: Full charge in 2 hours, or 80% in 45 minutes with fast charging

This supports round-the-clock operation with minimal downtime.