Product Description

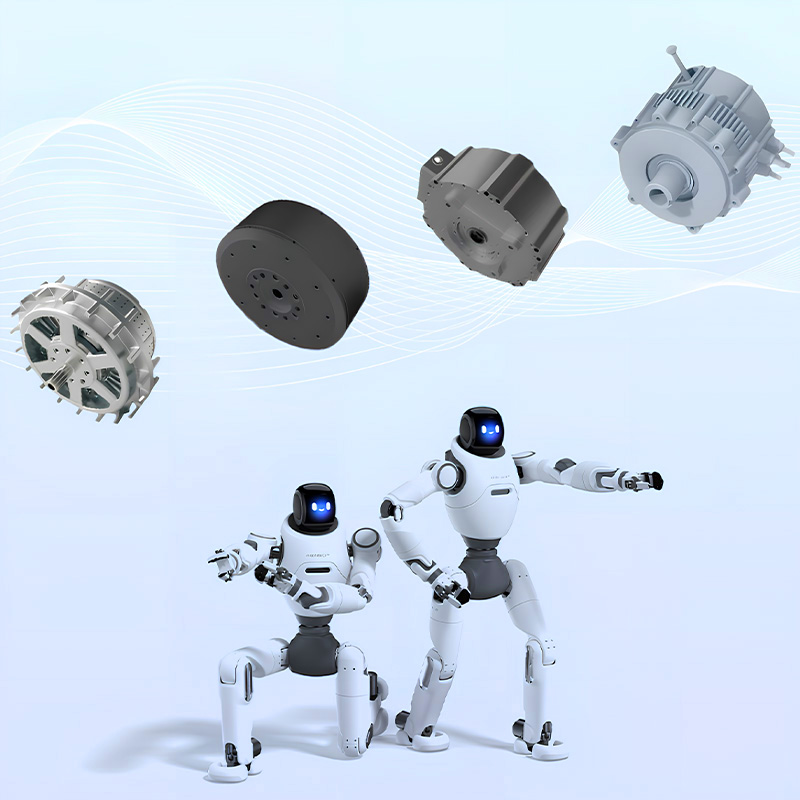

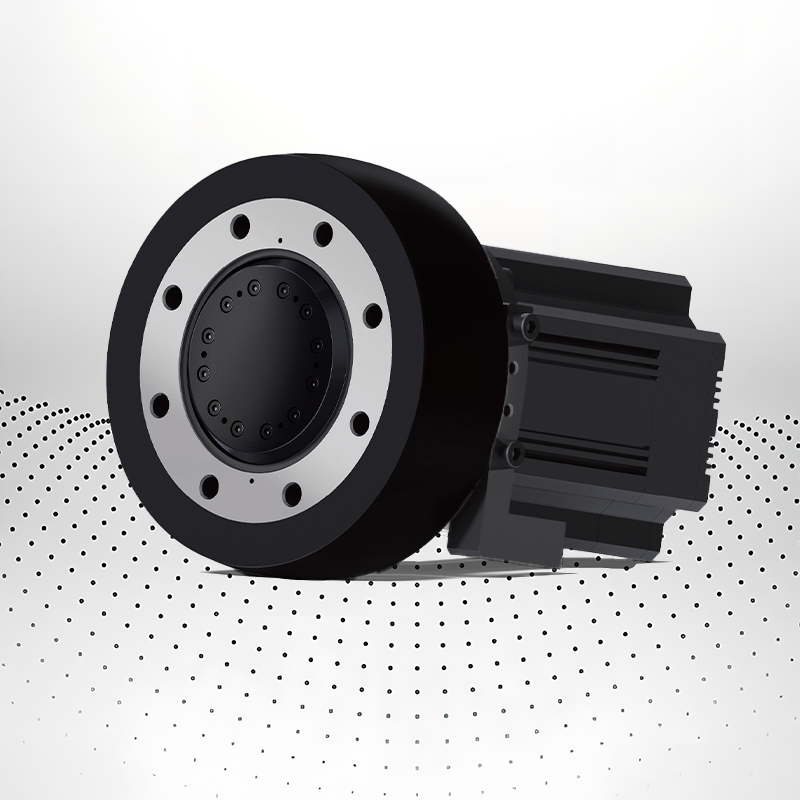

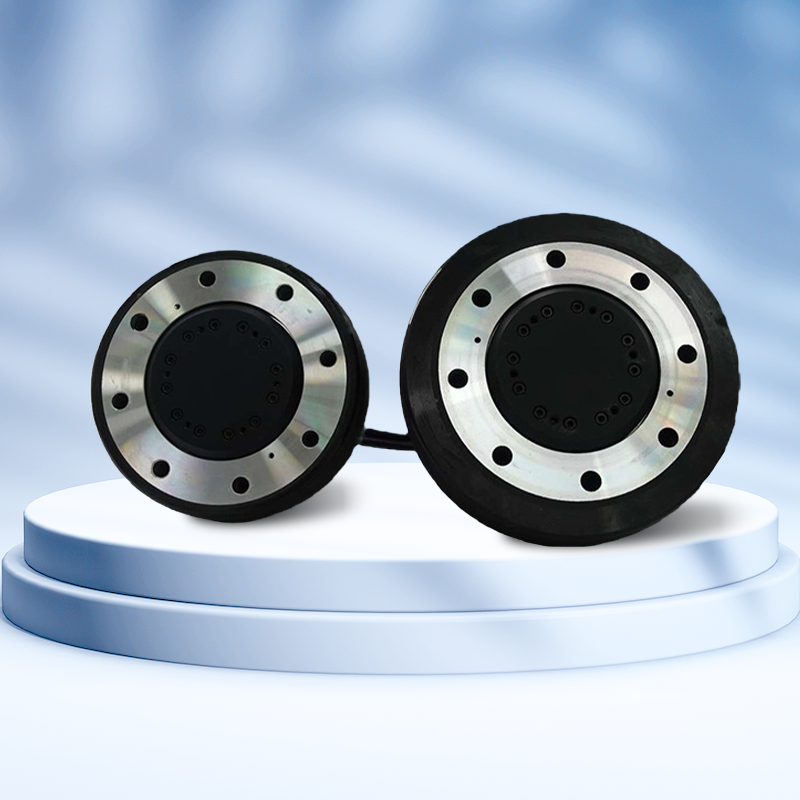

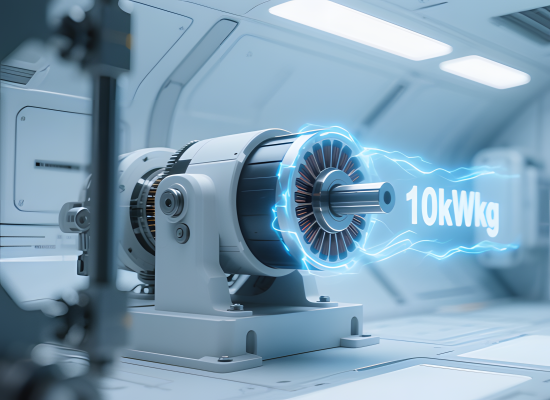

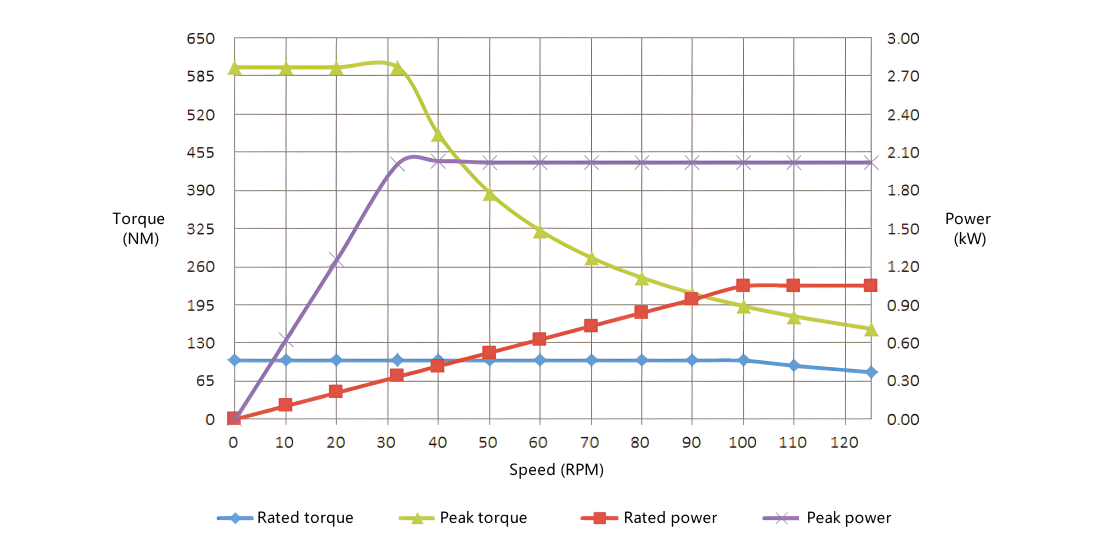

The W series axial flux motor breaks through traditional limitations with disruptive technology: it has a high power density of 10kW/kg, and its peak torque at low speed can reach 4 times that of traditional motors, but its volume is only 2/3 of that; it innovatively adopts a dual rotor + yokeless stator structure, with 90% copper-filled flat wire windings and amorphous nano-iron cores, and its energy efficiency reaches IE5 level, and the core loss is directly reduced by 80%. It is fully adaptable to new energy vehicles, industrial robots, AGV unmanned vehicles, drones, medical equipment, explosion-proof environments and other fields, redefining the new benchmark for efficient power!

Functional Features

[Explosive performance]

10kW/kg power density: Power jump under the same volume, suitable for compact scenes

Low speed and high torque: Peak torque is 4 times that of traditional motors, no pressure to start heavy loads

Volume and weight reduction of 1/3: Lightweight design, installation flexibility increased by 300%

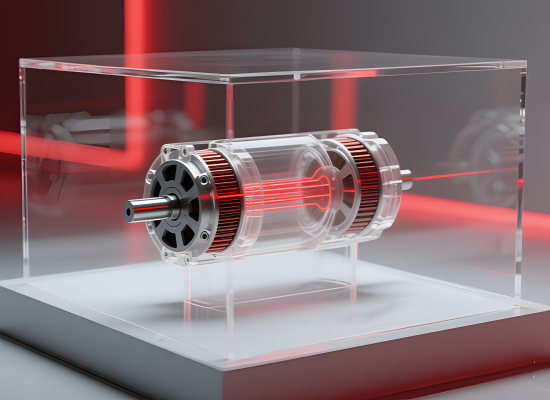

[Technological breakthrough]

Dual rotor + yokeless stator: maximized torque-to-weight ratio, more direct power transmission

90% copper-filled flat wire winding: increased conductivity, 25% lower heat generation

Amorphous nano-iron core: core loss reduced by 80%, IE5-level energy efficiency, power saving and stability

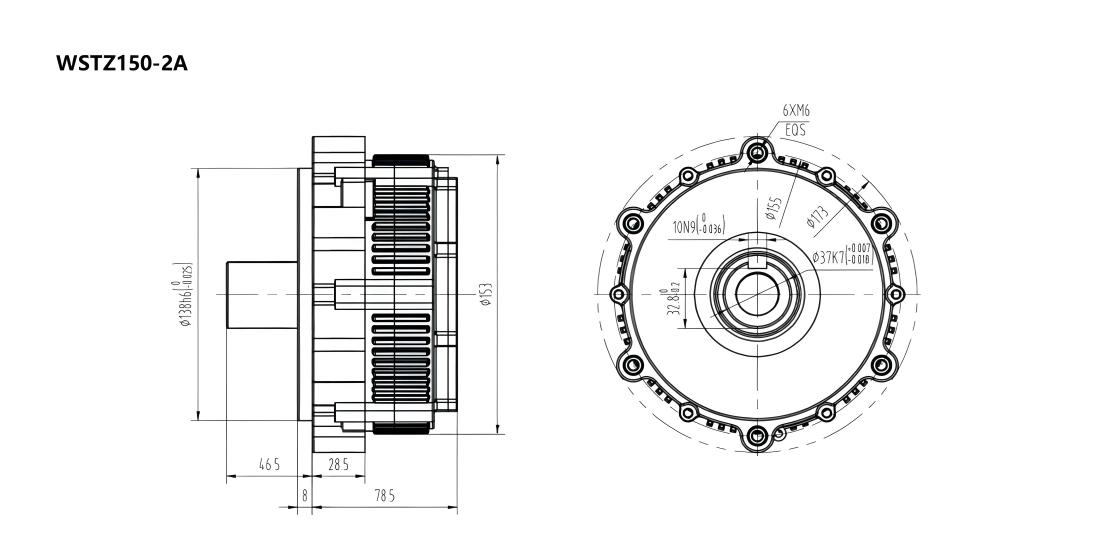

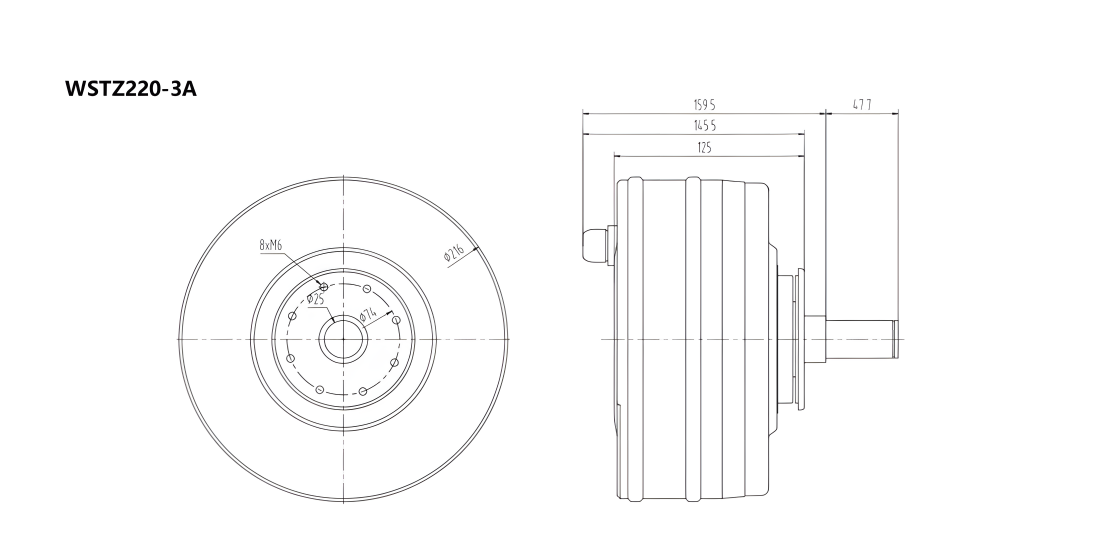

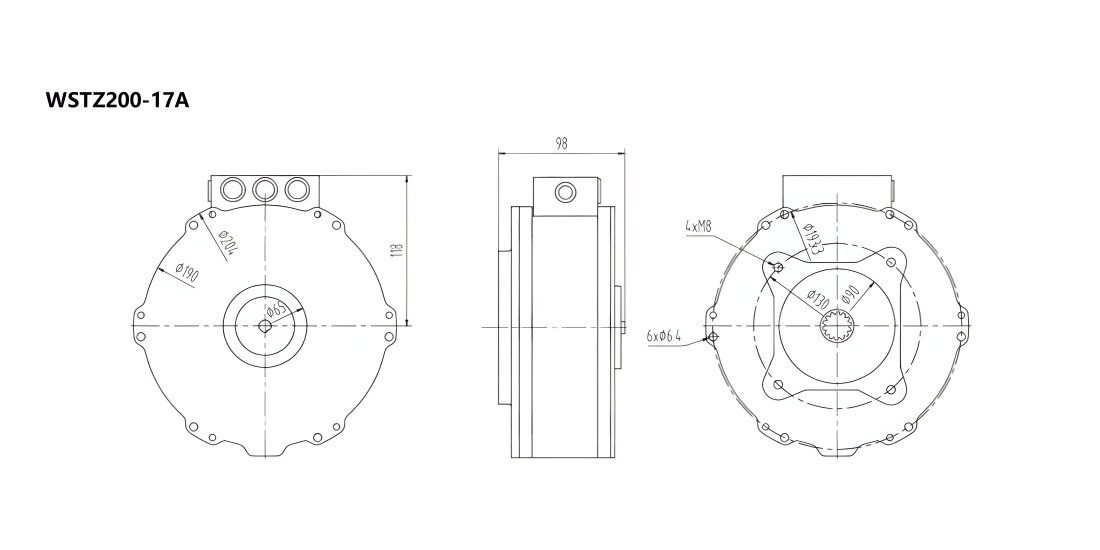

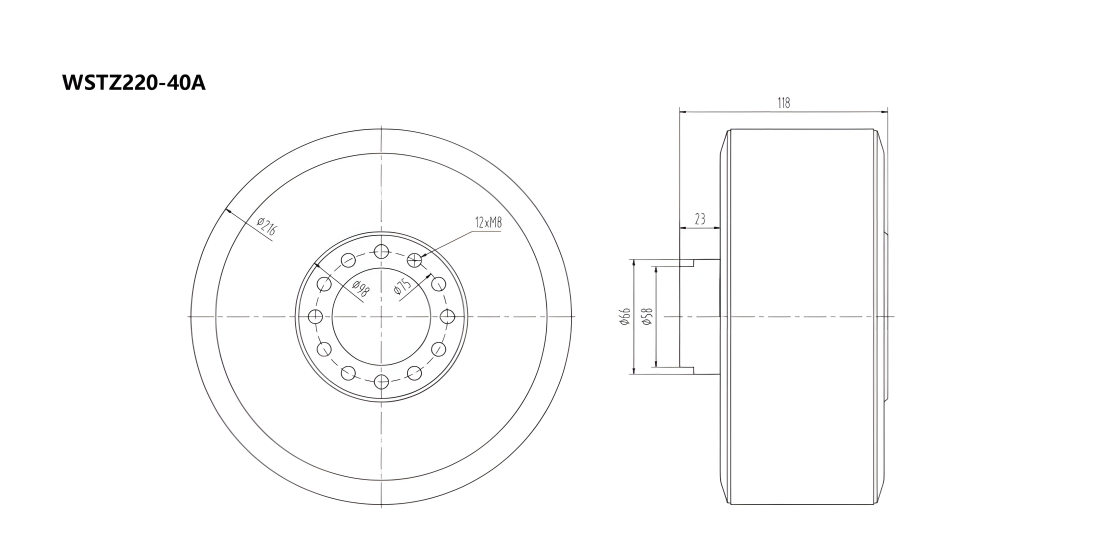

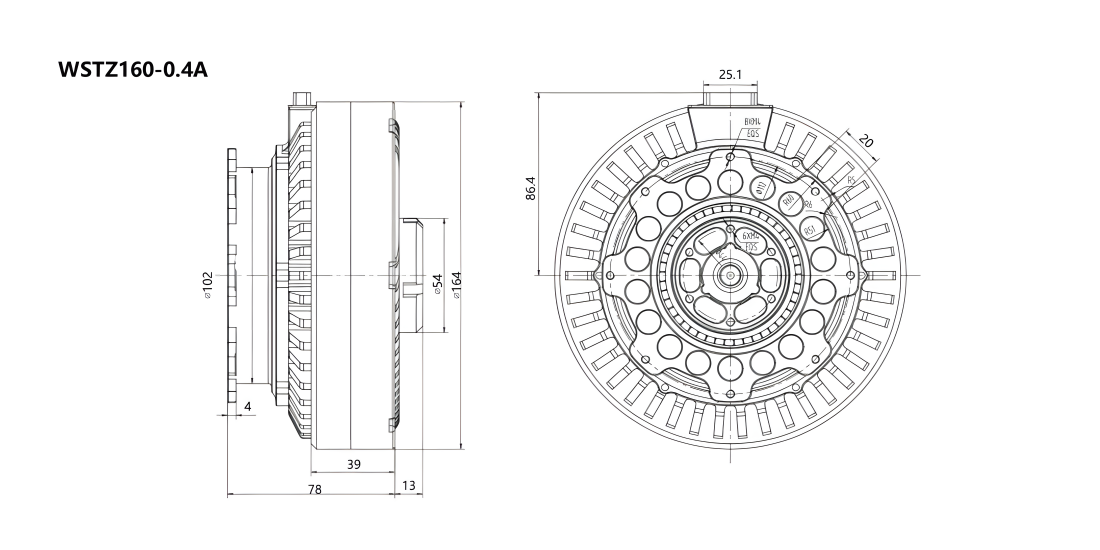

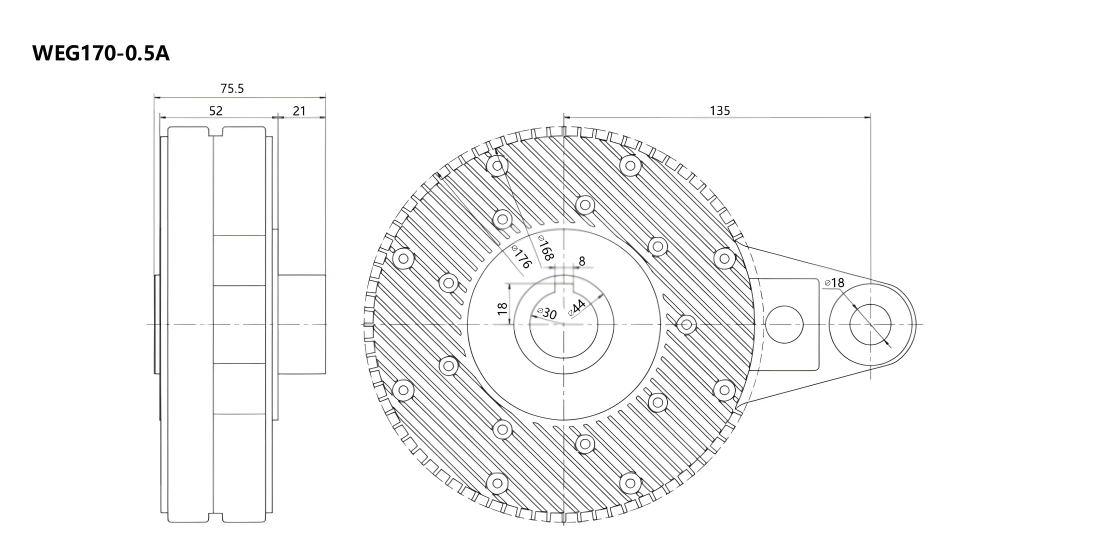

Dimensional drawing

Product parameters

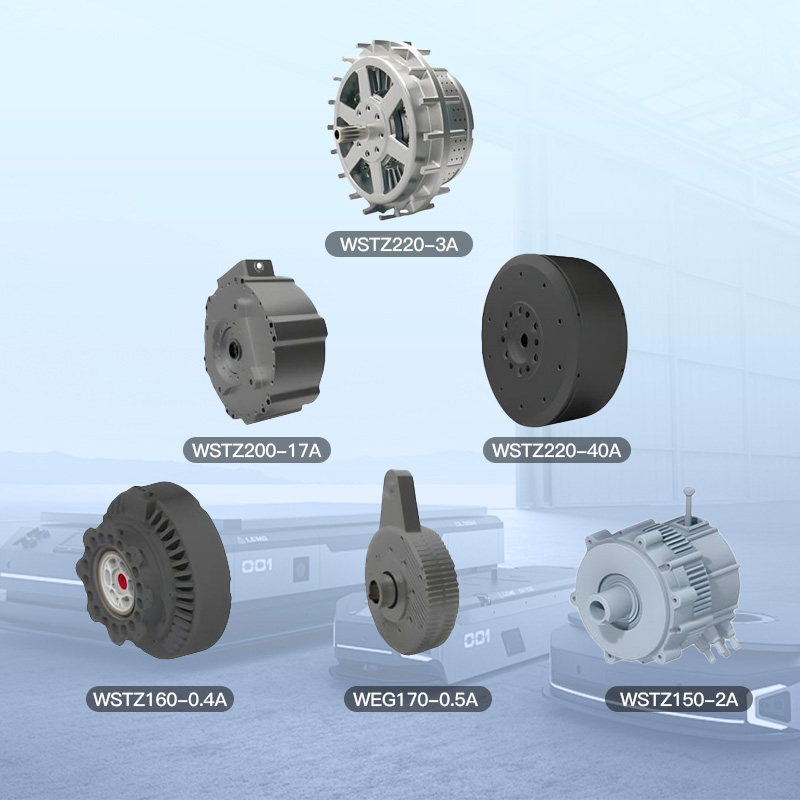

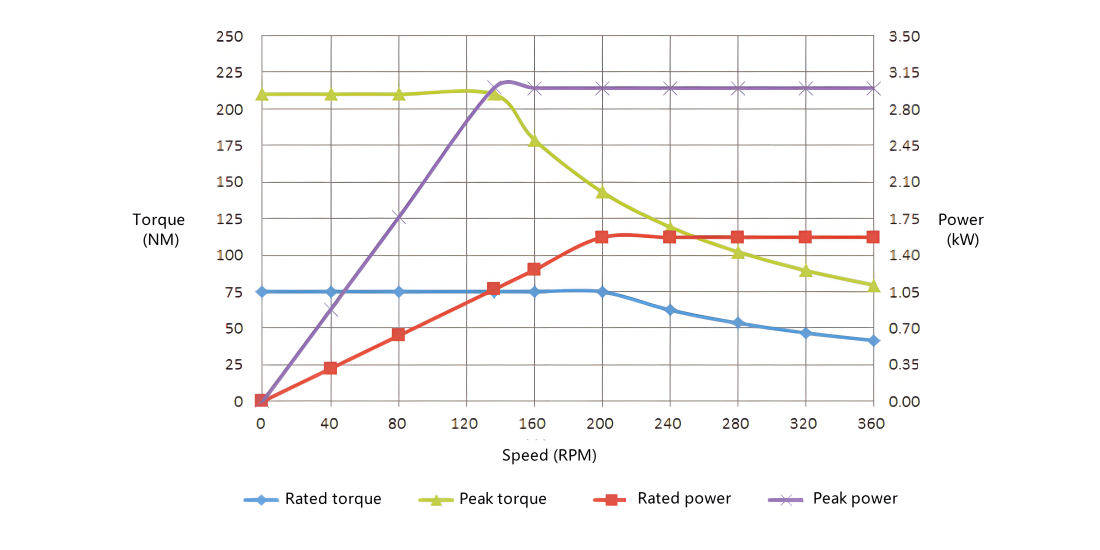

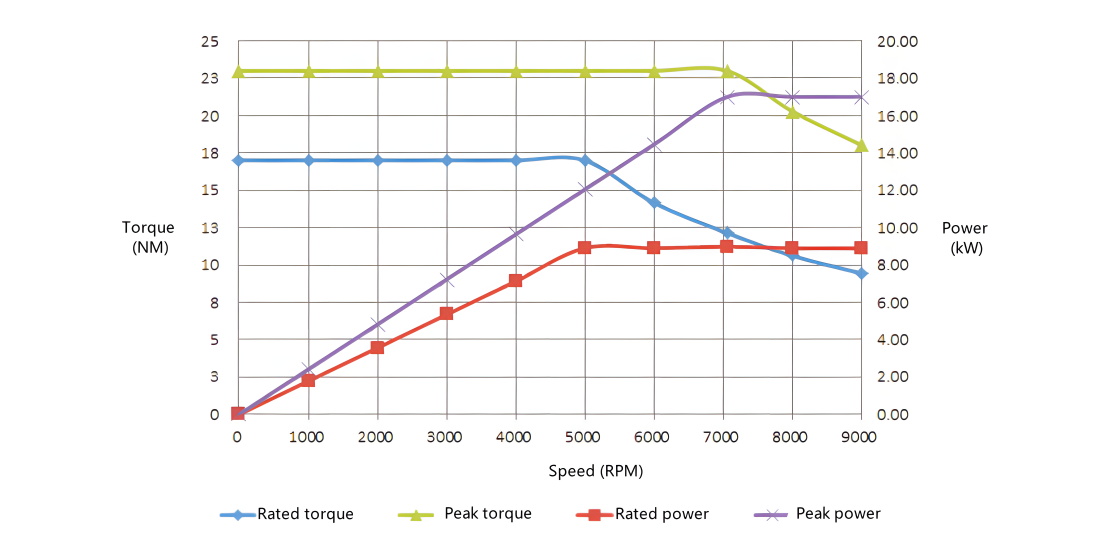

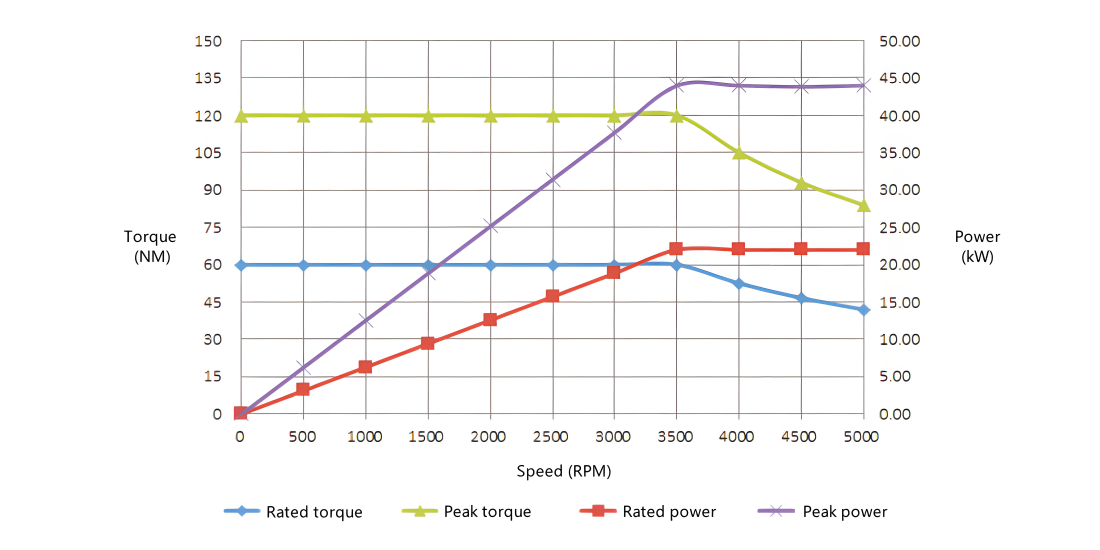

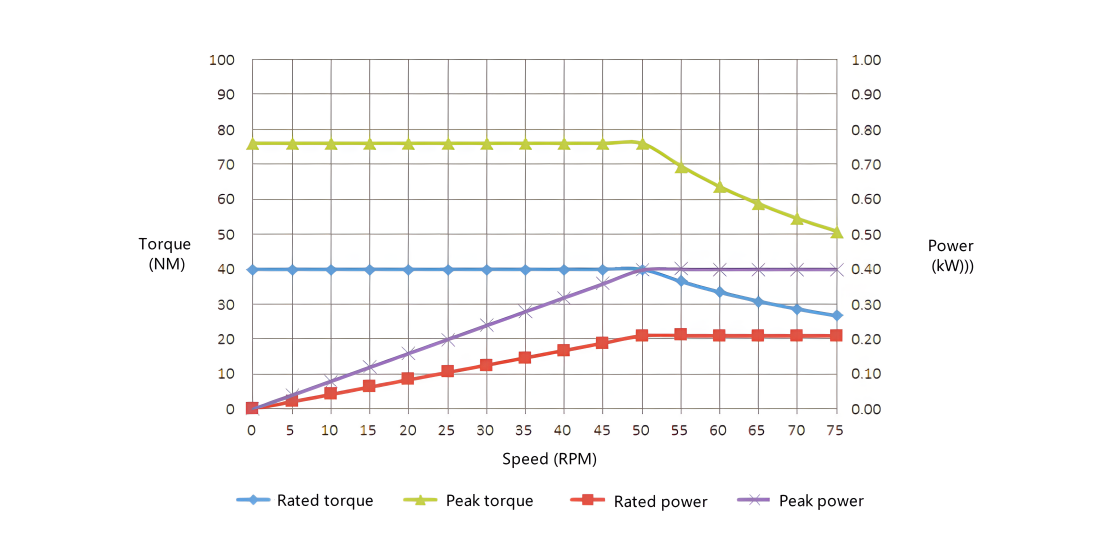

Model | WSTZ150-2A | WSTZ220-3A | WSTZ200-17A | WSTZ220-40A | WSTZ160-0.4A |

Bus Voltage | 48Vdc | 48Vdc | 120Vdc | 120Vdc | 36Vdc |

Reduction Ratio | As per customer requirements | As per customer requirements | / | / | As per customer requirements |

Rated Power | 1kW | 1.5kW | 9kW | 20kW | 0.2kW |

Peak Power | 2kW | 3kW | 17kW | 40kW | 0.4kW |

Rated Speed | As per customer requirements | As per customer requirements | 5000rpm | 3500rpm | As per customer requirements |

Peak Speed | 125rpm | 360rpm | 9000rpm | 5000rpm | 75rpm |

Rated Torque | 3.3Nm | 15Nm | 17Nm | 60Nm | 2.5Nm |

Peak Torque | 600Nm | 210Nm | 23Nm | 120Nm | 76Nm |

Rated Current | 20A | 65A | 130A | 230A | 8A |

Peak Current | 130A | 190A | 185A | 480A | 16A |

Protection Class | IP55 | IP55 | IP65 | IP65 | IP65 |

Insulation Class | H | H | H | H | H |

Cooling Method | Air Cooling | Air Cooling | Water Cooling | Air Cooling | Air Cooling |

Weight | 4.5kg | 7kg | 8kg | 12kg | 3kg |

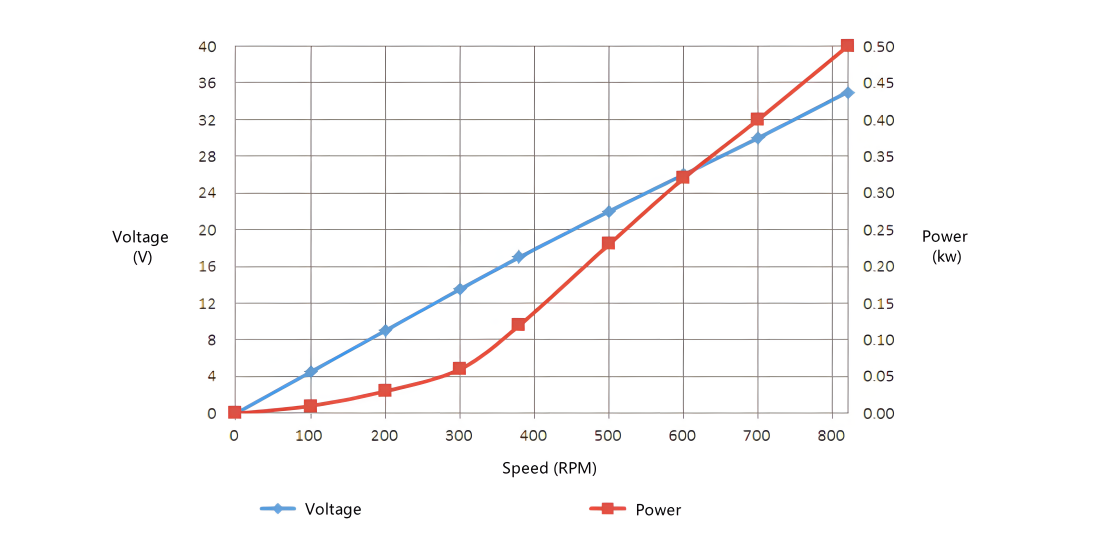

Model | WEG170-0.5A | ||

Rated Power | 0.12kW | Peak Power | 0.5kW |

Phase | 3 | Power Factor | 0.95 |

Rated Capacity | 0.126kVA | Peak Capacity | 0.526kVA |

Rated Voltage | 17V | Peak Voltage | 35V |

Rated Speed | 380rpm | Peak Speed | 820rpm |

Rated Speed | 380rpm | Peak Speed | 820rpm |

Rated Frequency | 63Hz | Peak Frequency | 137Hz |

Rated Current | 4.5A | Peak Current | 9A |

Prot.Class | IP65 | Ins.Class | H |

Cooling Method | Air Cooling | Weight | 5kg |

Application

The axial flux motor series, with its core advantages such as high torque, high speed, ultra-high-speed operation, high power density and precision control, covers a variety of scenarios such as heavy-duty AGV unmanned vehicles, logistics and warehousing equipment, high-speed chemical pumps, special vehicles, medical rehabilitation robots and train axle-end power generation. With lightweight design, multiple protections (IP55/65) and efficient heat dissipation solutions (natural cooling/water cooling), it provides customized power solutions for various fields.

Quality Assurance

We strictly follow international and industry advanced standards in production, and go through multiple quality inspection processes from raw material procurement to finished product delivery. Each axial magnetic field motor undergoes rigorous performance testing to ensure that its outstanding characteristics of light weight, small size, high efficiency, stability and reliability, excellent torque density and power density, provide a solid power foundation for your equipment operation.

After-sale guarantee

If the motor fails, our after-sales team will respond immediately and quickly arrange professional technicians to communicate with you to understand the details of the failure. We will provide you with remote technical guidance according to the specific situation to help you solve the problem. At the same time, we also provide you with regular return visits to understand the use of the motor and collect your opinions and suggestions in order to continuously optimize our products and services. When the product is upgraded, we will also notify you in time and provide you with corresponding technical support and solutions to keep your equipment in good performance.