Product Description

Servo hub motors ranging from 4 to 10 inches are suitable for all scenarios

Servo hub motors dedicated to service robots

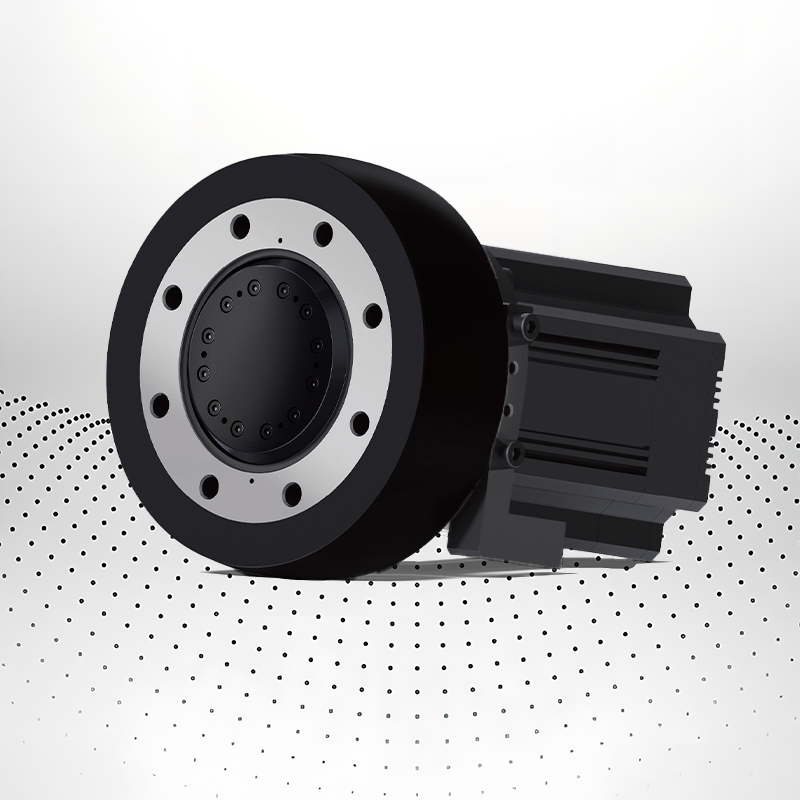

Integrated structure

High torque

Low noise

Lightweight design

Integrated structure: The motor, reducer, encoder, brake and other components are integrated within the wheel hub, eliminating the need for traditional transmission systems (such as drive shafts and differentials), and saving 30% to 50% of mechanical space.

▶ Application scenarios: Service robots can reduce the volume of their chassis and achieve more flexible body designs (such as delivery robots passing through narrow passages).

Lightweight advantages: Eliminating complex transmission components reduces the weight of the entire vehicle/robot by 15% to 20%, and energy consumption decreases simultaneously.

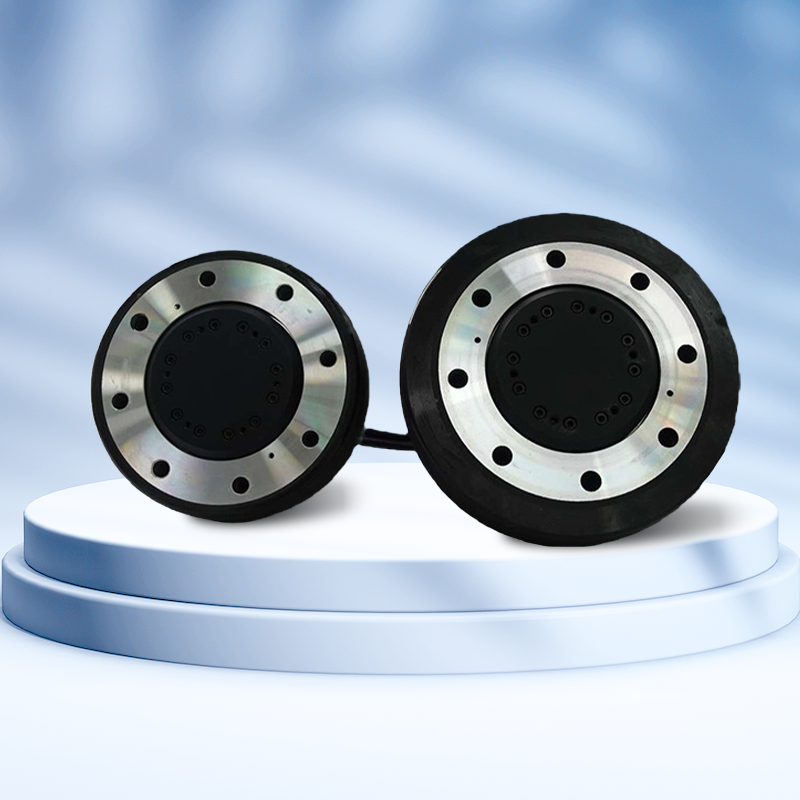

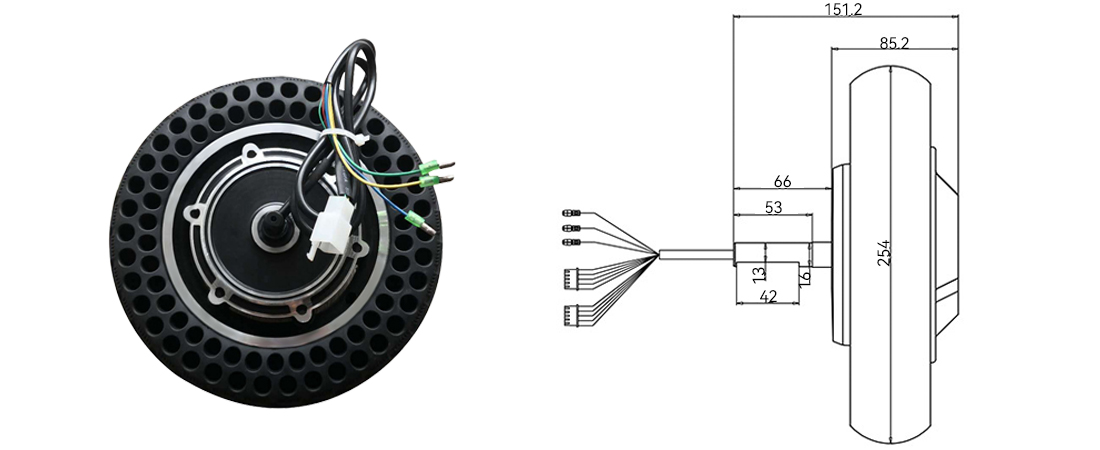

Product Display

REAL PICTURE DETAILS DISPLAY

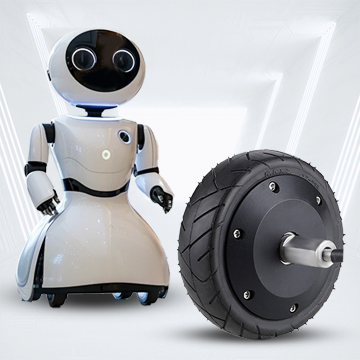

Application

Applied to service robots: such as food delivery robots, cleaning robots, delivery robots, welcoming robots, logistics delivery robots, shopping mall guidance robots, etc

Applied to the welcoming and reception robot

It is applied to the front-end guiding robot

Applied to food delivery robots

Applied to cleaning robots

Applied to shopping mall guide robots

Applied to logistics distribution robots

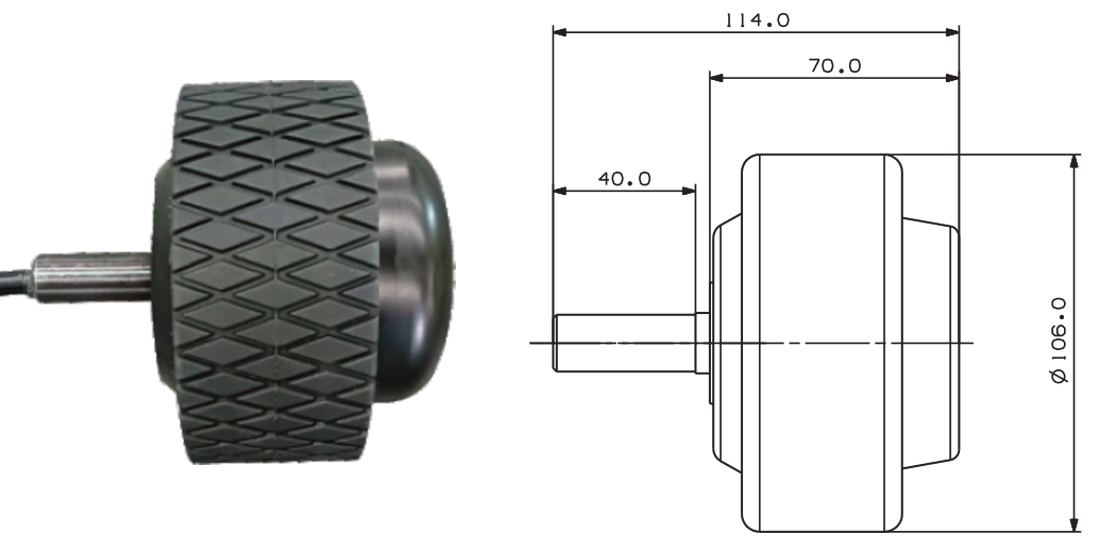

Product parameters

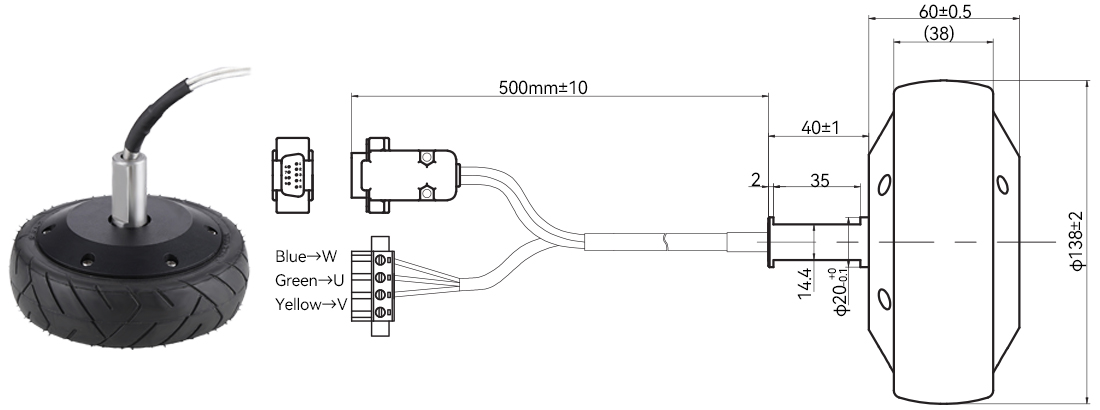

4"Encoder motor |

Name | Parameters | Name | Parameters |

Motor model | 4"Encoder motor | Efficiency | >70% |

Rated voltage | 24V | Maximum torque | >8N*M |

Rated torque | 4N*M | Polar logarithm | Ten pairs of poles |

Rated power | 75W | Steering (shaft end) | Clockwise/counterclockwise CW/ccw |

No-load rotational speed | 450RPM | Ambient temperature | -20~50℃ |

Encoder | 1024-line magnetic encoder | Preservation environment | -20~70℃ |

Preserve humidity | 5%~85%RH |

5.5"Magnetic encoder motor |

Name | Parameters | Name | Parameters |

Motor model | 5.5"Magnetic encoder motor | Efficiency | >70% |

Rated voltage | 24V | Maximum torque | >9N*M |

Rated torque | 5N*M | Polar logarithm | Ten pairs of poles |

Rated power | 150W | Steering (shaft end) | Clockwise/counterclockwise CW/ccw |

No-load rotational speed | 480RPM | Ambient temperature | -20~50℃ |

Encoder | 1024-line magnetic encoder | Preservation environment | -20~70℃ |

Preserve humidity | 5%~85%RH |

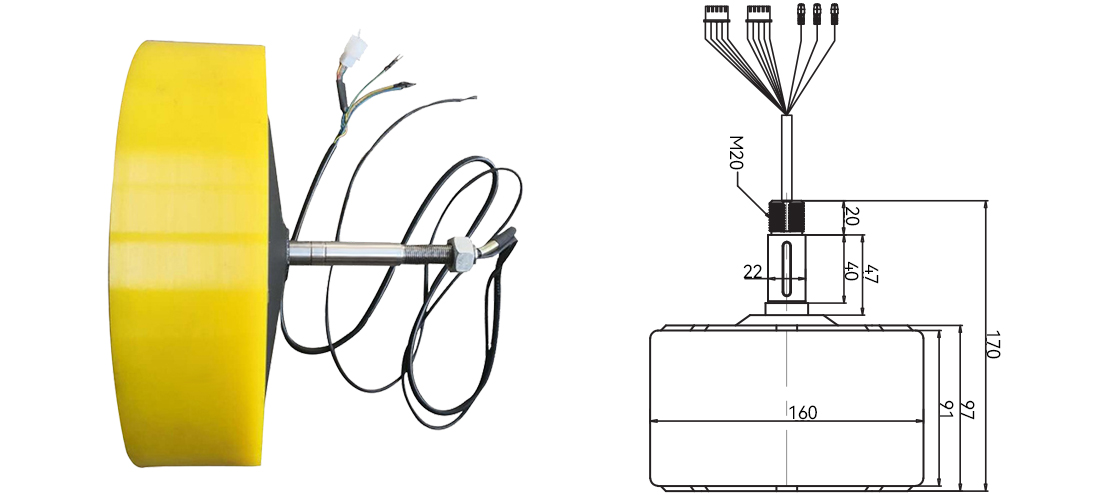

6.3"Magnetic encoder motor |

Name | Parameters | Name | Parameters |

Motor model | 6.3"Magnetic encoder motor | Maximum torque | >30N |

Rated voltage | 36V | Number of magnetic steel poles | 15 pairs of poles |

No-load current | ≤0.7A | Stator specification | Slot 27 |

No-load rotational speed | 330RPM±15 | Hall Angle | 120° |

Rated torque | >8N*M | Ambient temperature | -20~55℃ |

Rated power | 300W | Preservation environment | -20~70℃ |

Efficiency | >80% | Preserve humidity | 5%~85%RH |

Withstand pressure | 1.0KV <10mA |

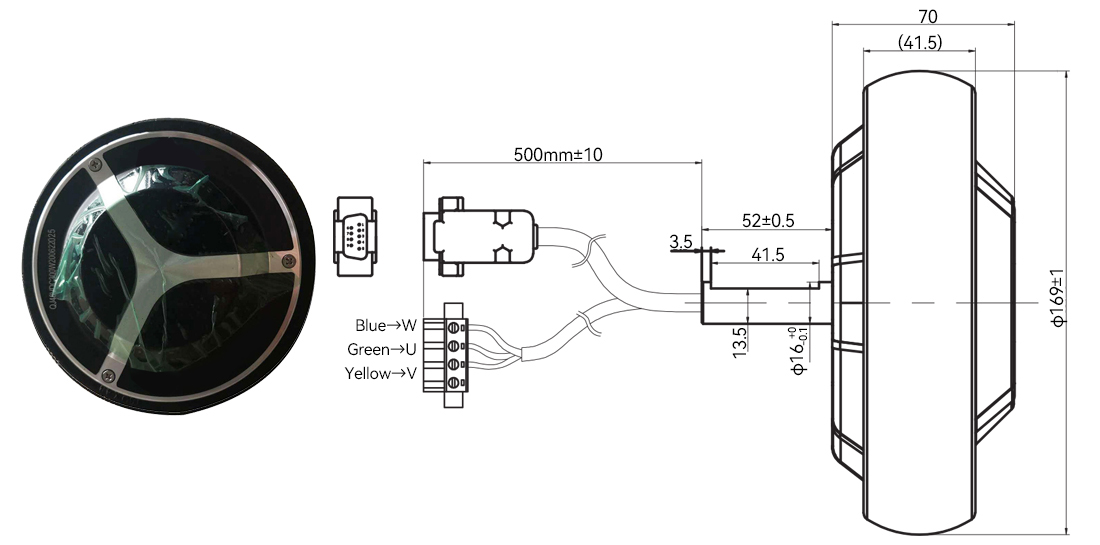

6.5"Magnetic encoder motor |

Name | Parameters | Name | Parameters |

Efficiency | 6.5"Magnetic encoder motor | Maximum torque | >=15N*M |

额定电压 | 48V | Number of magnetic steel poles | 15 pairs of poles |

额定电流 | 8A±1 | Stator specification | Slot 27 |

额定扭矩 | >5N*M | Hall Angle | 60° |

额定功率 | 200W | Ambient temperature | -20~55℃ |

空载转速 | 330RPM±10 | Preservation environment | -20~70℃ |

Efficiency | >80% | Preserve humidity | 5%~85%RH |

Withstand pressure | 1.0KV<10mA |

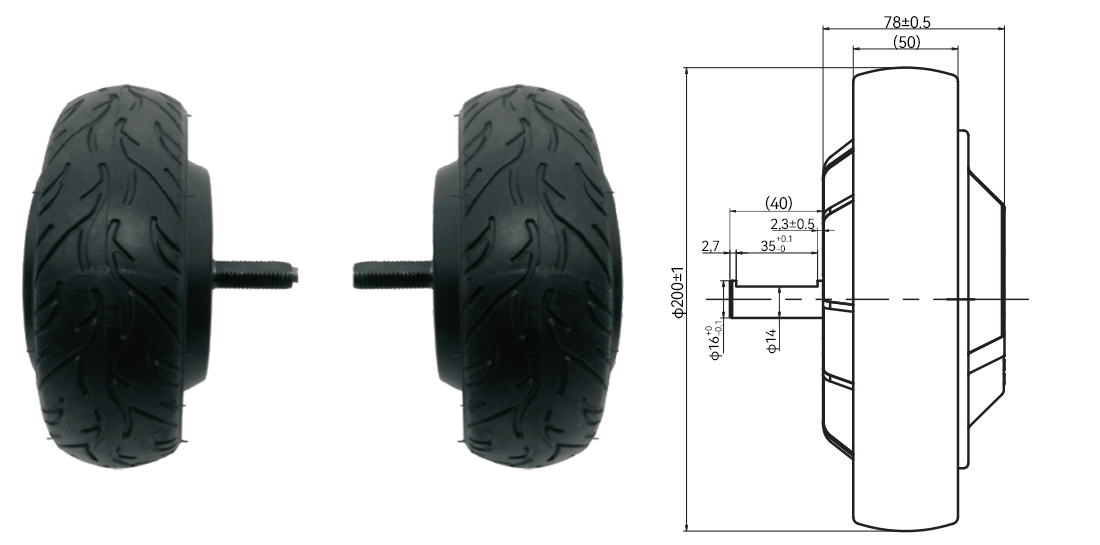

8"Magnetic encoder motor |

Name | Parameters | Name | Parameters |

Motor model | 8"Magnetic encoder motor | Maximum torque | >=15N*M |

Rated voltage | 48V | Number of magnetic steel poles | 15 pairs of poles |

Rated current | 8A±1 | Stator specification | Slot 27 |

Rated torque | >5N*M | Hall Angle | 60° |

Rated power | 200W | Ambient temperature | -20~55℃ |

No-load rotational speed | 330RPM±10 | Preservation environment | -20~70℃ |

Efficiency | >80% | Preserve humidity | 5%~85%RH |

Withstand pressure | 1.0KV<10mA |

10"Egg egg encoder motor |

Name | Parameters | Name | Parameters |

Motor model | 10"Egg egg encoder motor | Number of magnetic steel poles | 15 pairs of poles |

Rated voltage | 60V | Stator specification | Slot 27 |

No-load current | ≤1.2A | Hall Angle | 120° |

No-load rotational speed | 1330RPM±20 | Ambient temperature | -20~55℃ |

Rated torque | >15N*M | Preservation environment | -20~70℃ |

Rated power | 800W | Preserve humidity | 5%~85%RH |

Efficiency | >80% | Withstand pressure | 1.0KV <10mA |

10"Motor |

Name | Parameters | Name | Parameters |

Motor model | 10"Motor | Number of magnetic steel poles | 15 pairs of poles |

Rated voltage | 48V | Stator specification | Slot 27 |

No-load current | ≤1A | Hall Angle | 120° |

No-load rotational speed | 700RPM±20 | Ambient temperature | -20~55℃ |

Rated torque | >6N*M | Preservation environment | -20~70℃ |

Rated power | 350W | Preserve humidity | 5%~85%RH |

Efficiency | >80% | Withstand pressure | 1.0KV <10mA |

Service

Dedicated service, along the way

Warranty worry-free, extended repair, often return to promote optimization, peace of mind choice, all in control.

People-friendly and affordable Easy to install Quality Assurance Online guidance Manufacturer support Innovation

After-sale guarantee

After-sales service: We provide comprehensive after-sales technical support, if you encounter any problems in the process of use, the professional after-sales engineer team will respond quickly, through telephone, mail or remote assistance, to provide you with detailed solutions. We also provide regular return visits to our products to understand how they are used and to collect your feedback in order to continuously optimize our products and services. In addition, in strict accordance with the quality assurance policy, we provide free repair or replacement services for products with quality problems during the warranty period, so that you have no worries.