Product Description

The Autonomous Mobile Robot (AMR) is an intelligent, flexible, and highly adaptable mobile automation solution designed to optimize material transport and logistics in modern industrial environments. Equipped with advanced sensors, AI-driven navigation, and dynamic path planning, the AMR safely and efficiently navigates complex facility layouts without requiring fixed infrastructure.

Its modular design allows for easy integration with a variety of payload modules, such as conveyors, robotic arms, or custom tooling, making it ideal for diverse applications including warehouse automation, manufacturing support, and intralogistics.

With real-time data connectivity and fleet management capabilities, the AMR provides scalable, autonomous operations that reduce labor costs, improve workflow efficiency, and enhance workplace safety. Its collaborative nature enables seamless coexistence with human workers, supporting Industry 4.0 smart factory initiatives.

Advantages of AMR Robot

Flexible Navigation: Uses AI and sensor fusion to navigate dynamically in complex, changing environments without fixed guides.

Increased Productivity: Automates repetitive transport tasks, freeing up human workers for higher-value activities.

Scalable Fleet Management: Easily add or redeploy AMRs with centralized control software for optimized workflows.

Improved Safety: Equipped with advanced obstacle detection and safety protocols to work alongside humans safely.

Cost-effective: Reduces labor costs and minimizes downtime with autonomous operation and quick deployment.

Versatile Integration: Compatible with different payloads and tools, adaptable across various industries and applications.

| Industry | Application Area | Typical Tasks |

| Warehouse | Intralogistics | Transporting goods between zone |

| Manufacturing | Material Supply | Delivering parts to assembly lines |

| Healthcare | Hospital Logistics | Moving medical supplies and equipment |

| Retail | Stock Replenishment | Restocking shelves and inventory |

| E-commerce | Order Fulfillment | Picking and transporting packages |

Product Features

Autonomous Navigation: SLAM-based localization and real-time path planning with LiDAR and vision sensors.

Modular Payload Options: Supports conveyors, robotic arms, shelves, or custom fixtures for specific tasks.

Real-time Fleet Management: Cloud or on-premises software for task scheduling, monitoring, and analytics.

Robust Safety Systems: 2D/3D LiDAR, ultrasonic sensors, emergency stops, and safety-rated laser scanners.

User-friendly Interface: Intuitive touchscreen HMI and integration APIs for easy programming and control.

Long Battery Life: Lithium-ion batteries supporting multiple shifts with quick charging options.

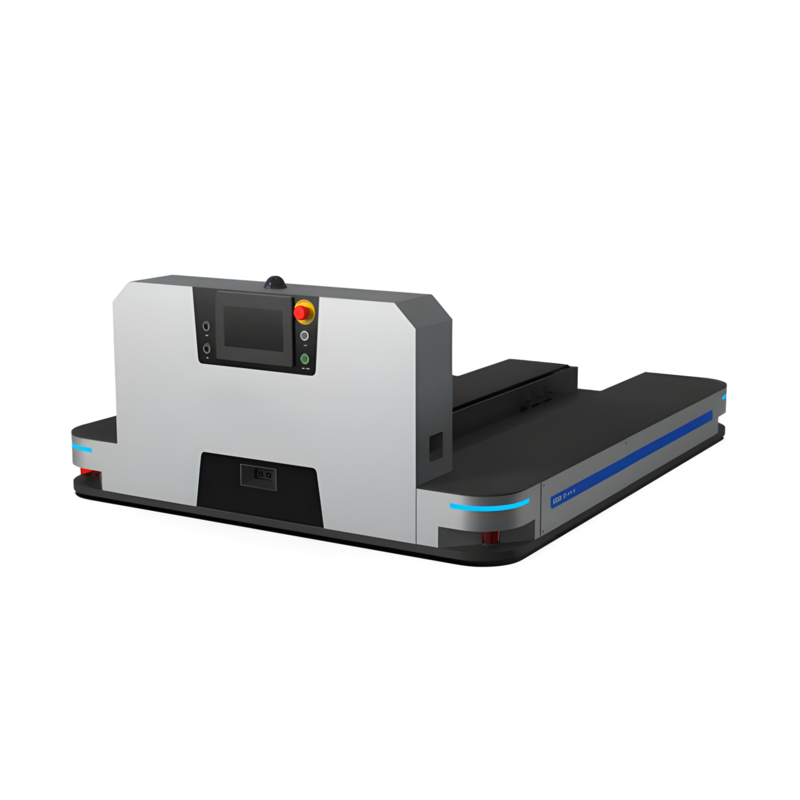

Structure Diagram

Product parameters

| Parameter | Specification |

| Dimensions (L × W × H) | 1000 mm × 700 mm × 400 mm |

| Payload Capacity | 100 – 500 kg |

| Maximum Speed | 1.0 – 1.5 m/s |

| Navigation Technology | SLAM with LiDAR and Vision Sensors |

| Battery Type | Lithium-ion, 48V, 50Ah – 100Ah |

| Battery Life | 8 – 12 hours (continuous operation) |

| Charging Metho | Automatic / Manual charging |

| Communication Interface | Wi-Fi, Ethernet |

| Safety Features | 2D/3D LiDAR, Emergency Stop, Bumper Sensors |

Customer Case

Automotive Industry

Electronics Industry

Pharmaceutical Industry

FAQ

| Question | Answer |

| What is an AMR robot? | An AMR (Autonomous Mobile Robot) is a self-driving robot designed to transport materials autonomously within facilities |

| How does the AMR navigate? | It uses SLAM technology combined with sensors like LiDAR and cameras to map and navigate environments dynamically. |

| Can AMRs work safely around humans? | Yes, AMRs have advanced safety features such as obstacle detection, emergency stops, and speed control to operate safely alongside people |

| What types of payloads can an AMR carry? | AMRs support various payloads including shelves, conveyors, robotic arms, and custom tools depending on the task. |

| How long does the AMR operate on a single charge? | Battery life typically ranges from 8 to 12 hours depending on usage and battery capacity. |