Product Description

High-quality hot-dip galvanizing service for steel structures, cable trays, gratings, pipes, utility poles, and small components. Provides durable corrosion protection in accordance with international standards such as ISO 1461, ASTM A123/A153, and BS EN. Suitable for industrial, infrastructure, and construction applications.

Our Work shop

|

|

|

|

Our service

|

|

|

|

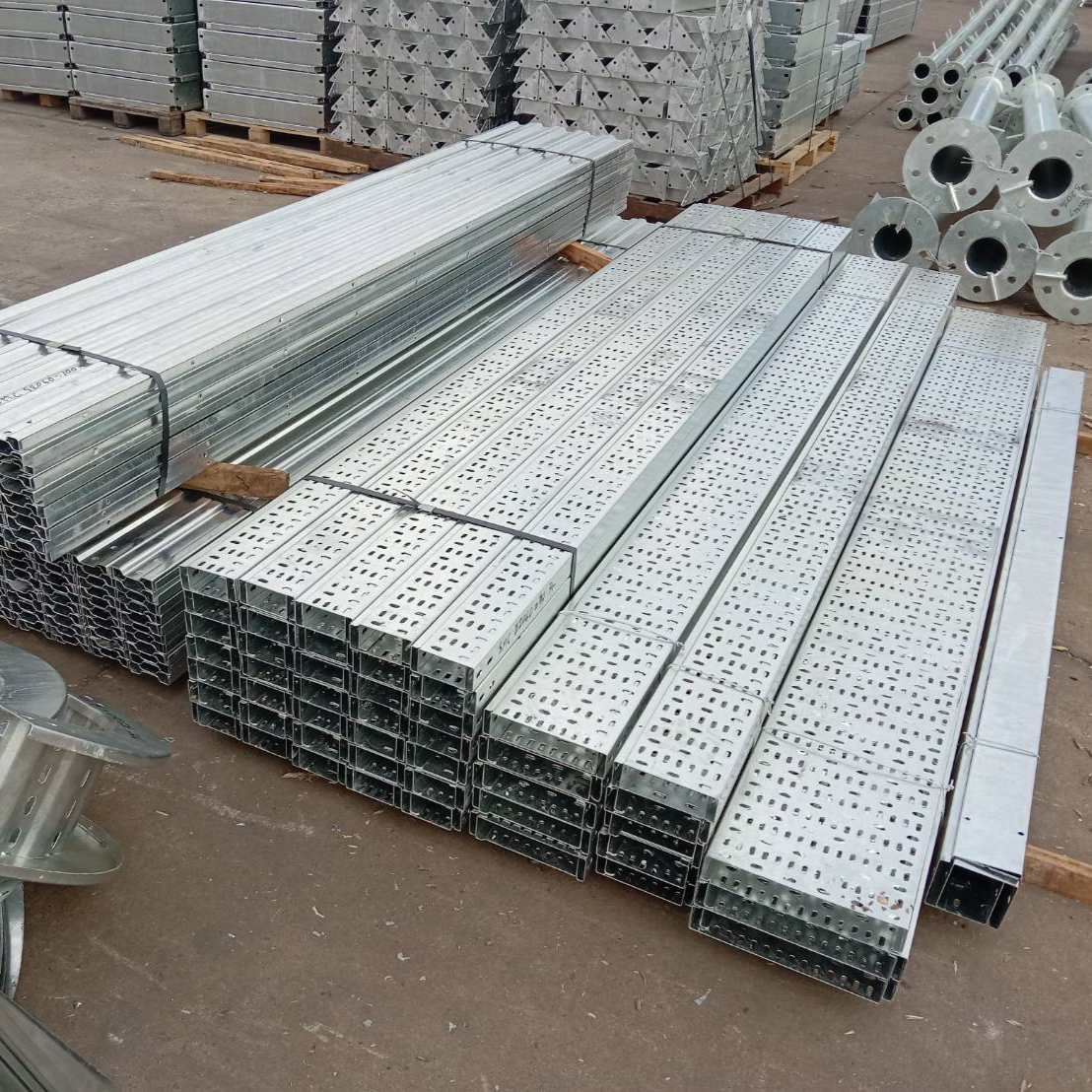

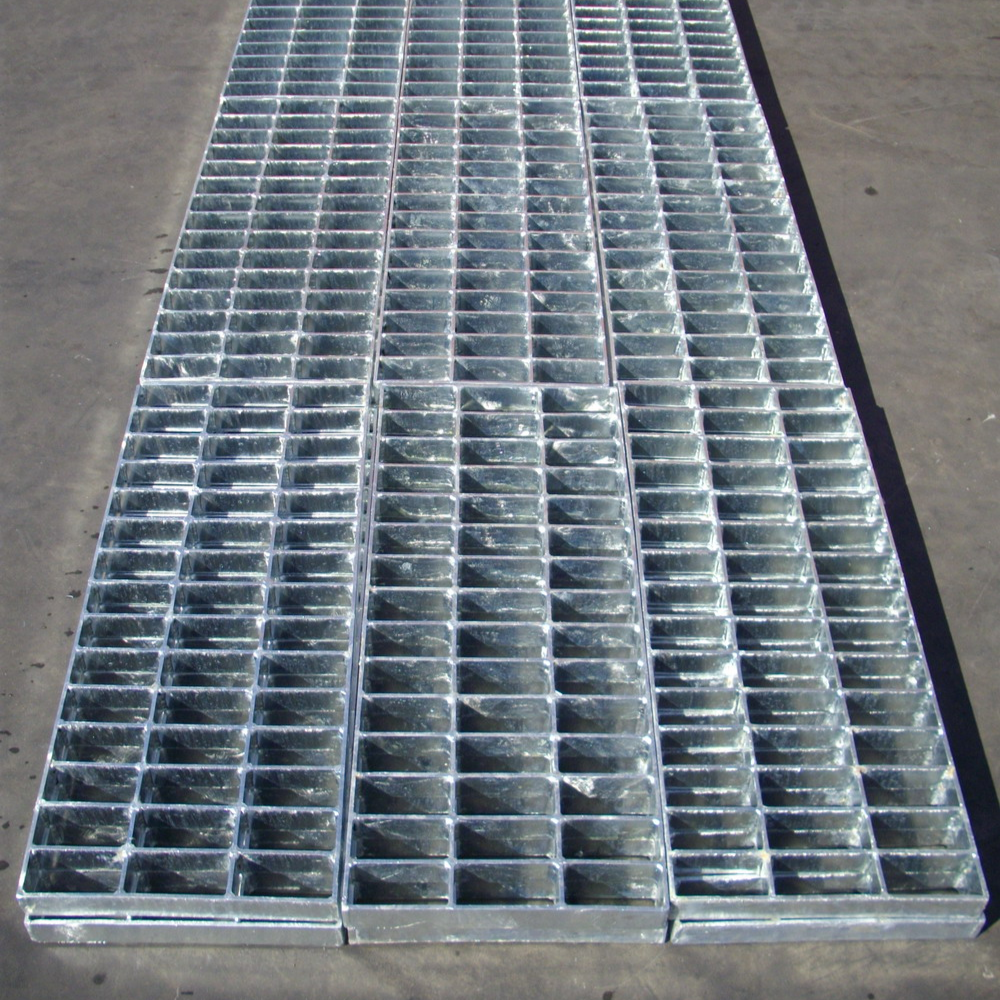

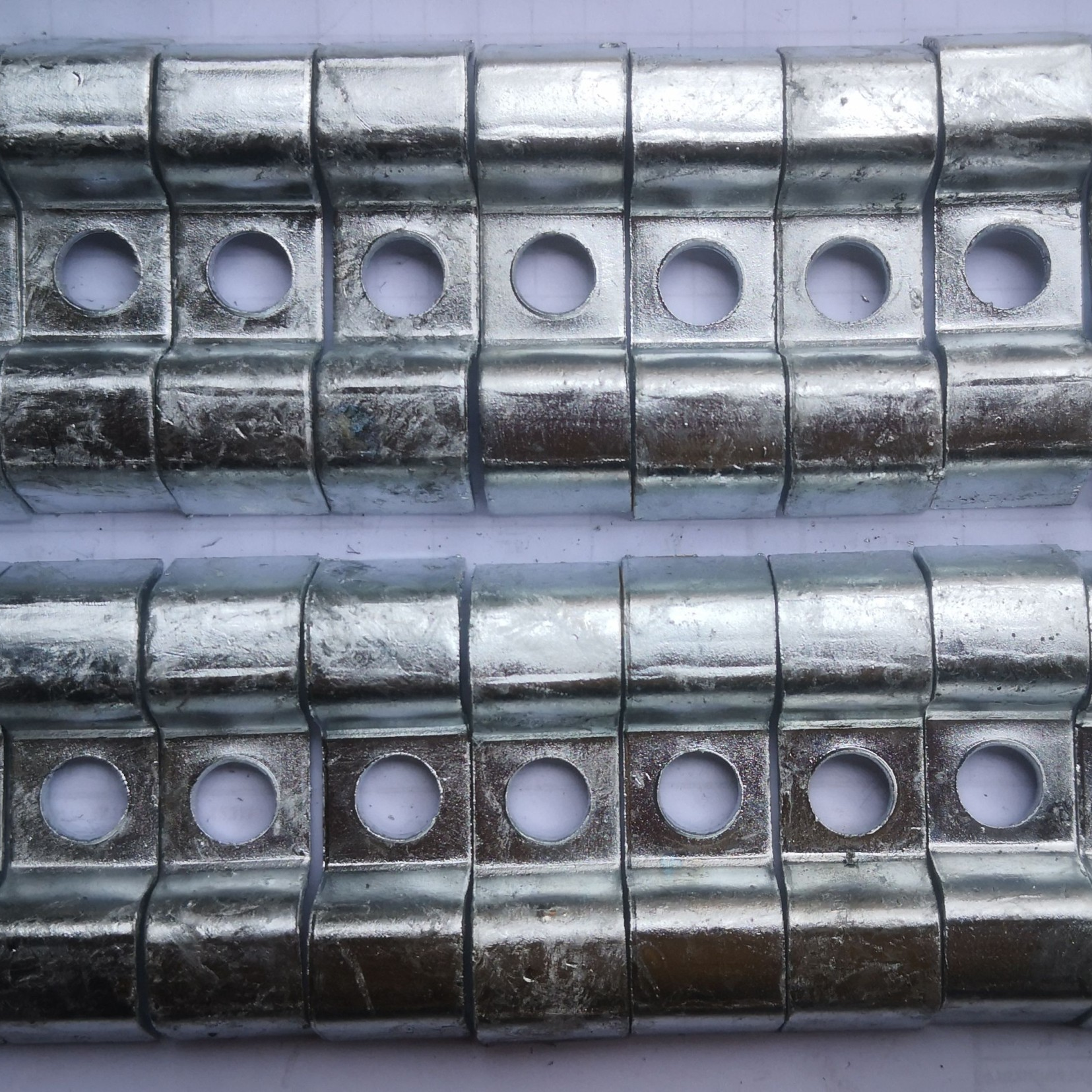

Building structure plating | Plated electrical rail equipment | Plated grid | Plated box steel |

|

|

|

|

Oil tank plating | Plated structures/utility equipment | Plated wire mesh | Others |

Galvanizing is a plating to prevent rust on the surface of steel, resulting in a longer service life of the steel. It is suitable for work that requires exposure to hot air and high humidity, such as outdoor installation structures.

The company's plating system is in accordance with international standards or the standards specified by the customer under the production control of the ISO 9001:2015 quality management system with a plating quality certificate. Customers can be 100% confident in our plating process because we inspect the quality at every stage of production to meet the highest customer needs.

The company provides galvanizing services for a variety of products, such as electric poles, communication poles, guardrails, various sizes of steel pipes, as well as all types of welded steel structures, etc. for companies, shops, and the general public.

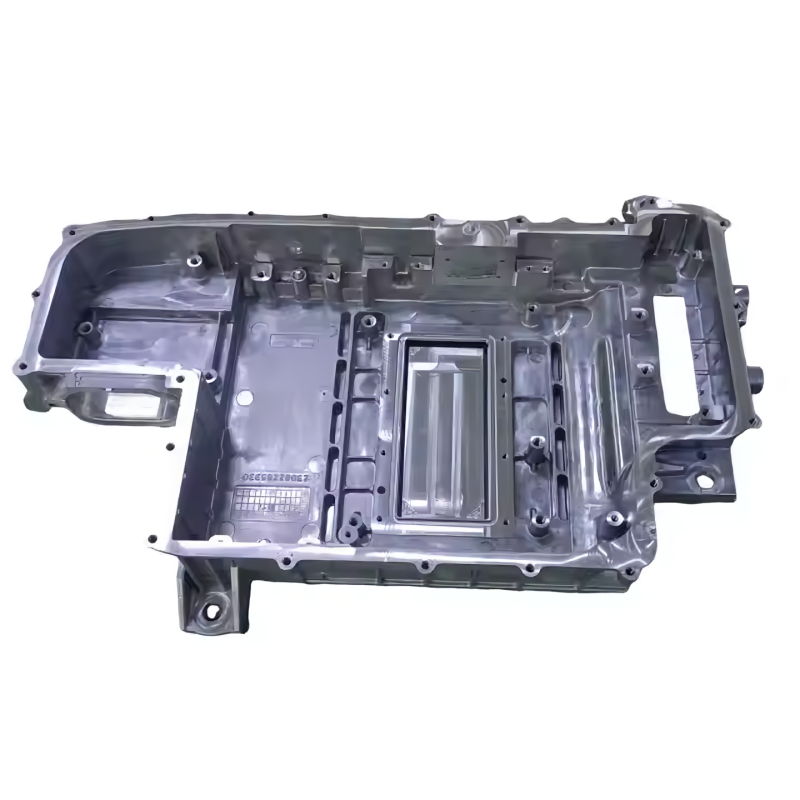

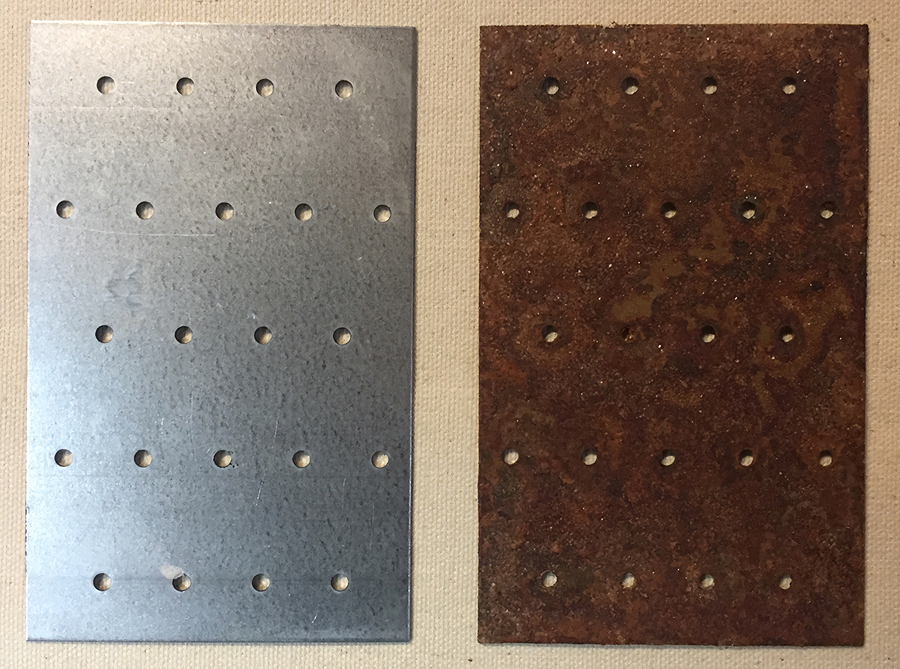

Our products before and after galvanizing

Comparison of processing technologies

Technology | Working Principle | Advantages | Limitations | Best Applications |

Hot Dip Galvanizing | Dipping steel in molten zinc (~450°C) | - Excellent long-term corrosion resistance- Coats all surfaces, including internal cavities- Highly durable | - Surface may be rough- High temperature may distort thin parts | - Outdoor steel structures- Construction & power industry- Marine parts |

Electroplating (Zinc/Nickel/Chrome) | Electrochemical deposition of metal coating | - Smooth and shiny finish- Precise thickness control- Ideal for small components | - Lower corrosion resistance than HDG- Not suitable for harsh outdoor environments | - Precision parts- Decorative fittings- Tools & hardware |

Cold Galvanizing (Zinc Spray) | Zinc-based paint or spray coating at room temperature | - Easy application- Suitable for touch-ups and fieldwork- No heat distortion | - Thinner coating- Less durable and protective than HDG | - On-site repair- Internal steelwork- Heat-sensitive components |

Powder Coating | Electrostatic application of powder, then cured at ~200°C | - Aesthetic appearance with customizable colors- Scratch-resistant- Environmentally friendly | - Not as corrosion-resistant as HDG- Poor coverage in recessed areas- Requires clean surface | - Metal furniture- Home appliances- Indoor decorations |

Product parameters

Parameter | Description | To Be Provided By |

Workpiece Dimensions | Length × Width × Height / Diameter of each part | ✅ Customer |

Material Type | Type of steel (e.g., mild steel, cast iron, alloy steel) | ✅ Customer |

Surface Condition | Painted, rusty, oily, new, etc. | ✅ Customer |

Required Coating Standard | ISO 1461, ASTM A123, BS EN 1461, or custom thickness (e.g., ≥ 85 µm) | ✅ Customer |

Vent/Drain Hole Requirement | Especially for hollow or enclosed parts | ✅ Customer (or request factory to drill) |

Post-Treatment Instructions | Additional finishing: passivation, epoxy coating, removal of zinc drips | ✅ Customer (if needed) |

Quantity & Batch Info | Total number of items or estimated weight per batch | ✅ Customer |

Delivery Conditions | Packing, labeling, delivery deadline, or site delivery | ✅ Customer |

Special Notes | Any restrictions, visual inspection levels, or quality tolerances | ✅ Customer |

Advantages and highlights of the factory

| 10+ Years of Professional Processing Experience |

| High-Precision Equipment |

| Rapid Inspection & Reliable After-Sales Support |

| ISO 9001 Certified Quality Management |

| One-Stop Service from Design to Mass Production |

Custom Process

Initial Inquiry

Submission of Drawings

Quotation

Pre-Production Check

Surface Preparation

Hot Dip Galvanizing

Cooling, Inspectio

Packing & Delivery