Product Description

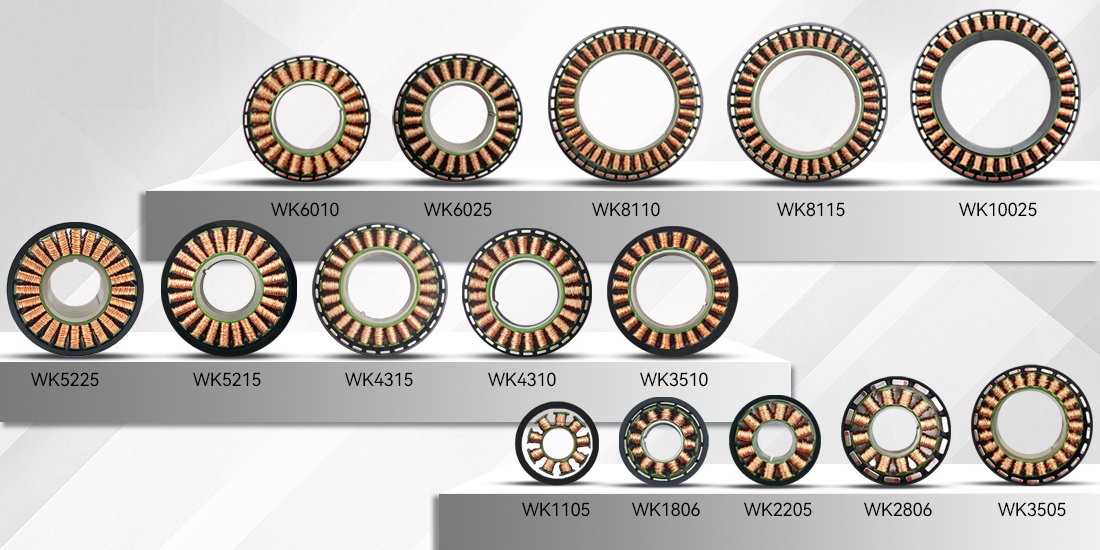

WK's full range of frameless motors

Functional Features

High torque output

By eliminating the transmission link of the reducer, the energy efficiency is increased to over 90%, reducing mechanical losses and transmission errors.

Large hollow channel

Simplify the internal wiring of the equipment, avoid the entanglement of external cables, and enhance the reliability of the system (such as in the anti-vibration scenario of aerospace equipment).

Low noise and silent

Reduce environmental noise pollution and be suitable for human-machine collaboration scenarios (such as restaurant food delivery robots and rehabilitation medical equipment).

Flat design

Save equipment space, support modular integration, and reduce the complexity of the overall machine design

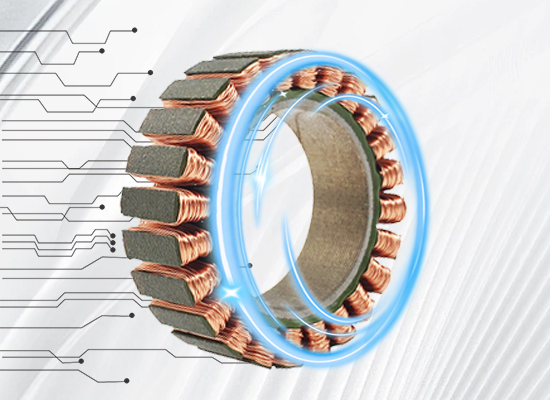

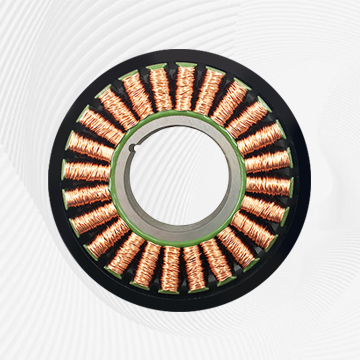

Product Display

REAL PICTURE DETAILS DISPLAY

Application

Application scenarios: robot joints (collaborative robots, bionic robots), aerospace servos, precision medical equipment, semiconductor processing, industrial automation fields, new energy and automation fields, unmanned aerial vehicle propulsion systems, etc.

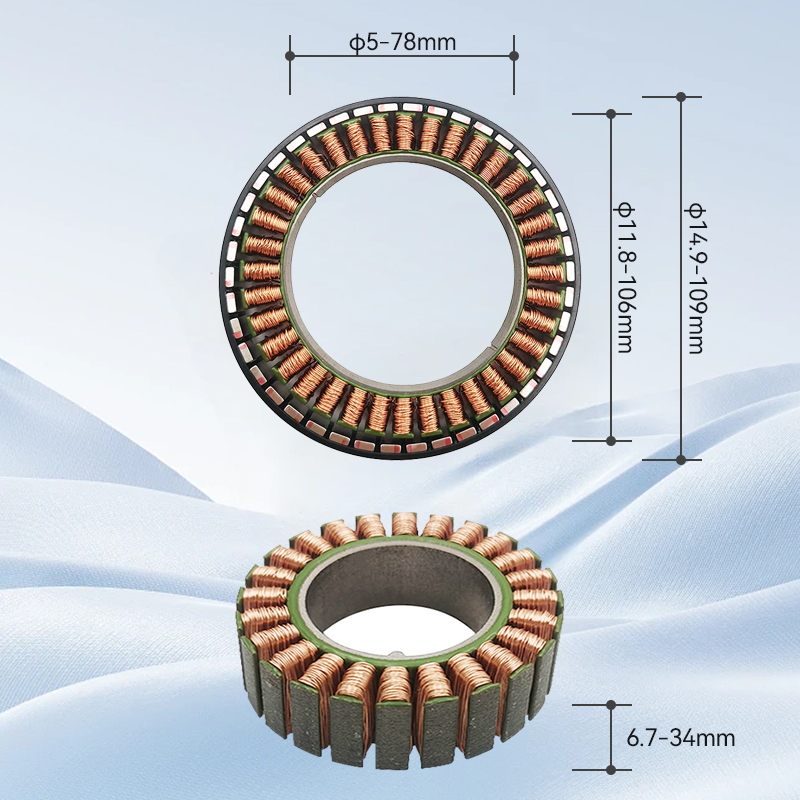

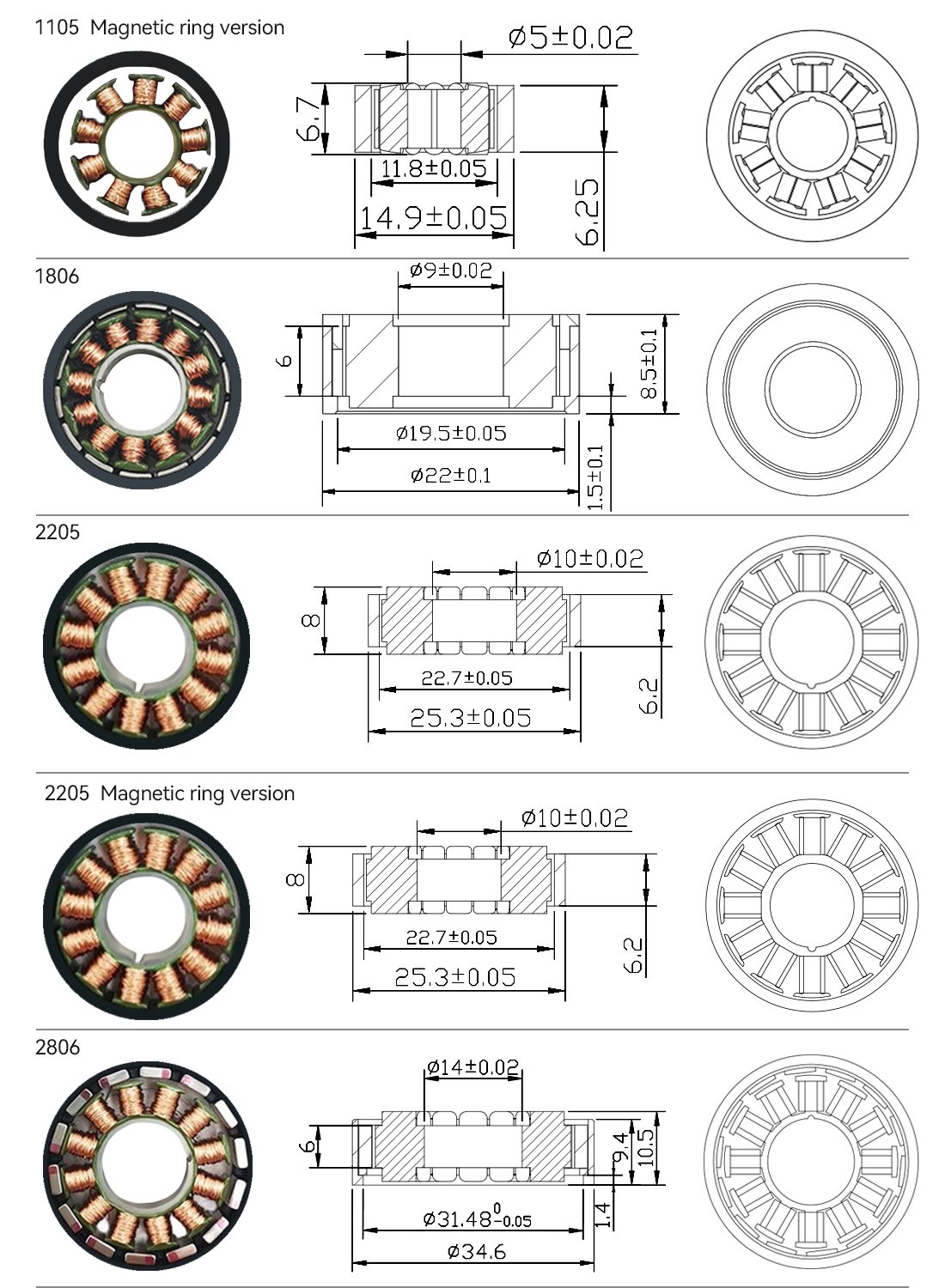

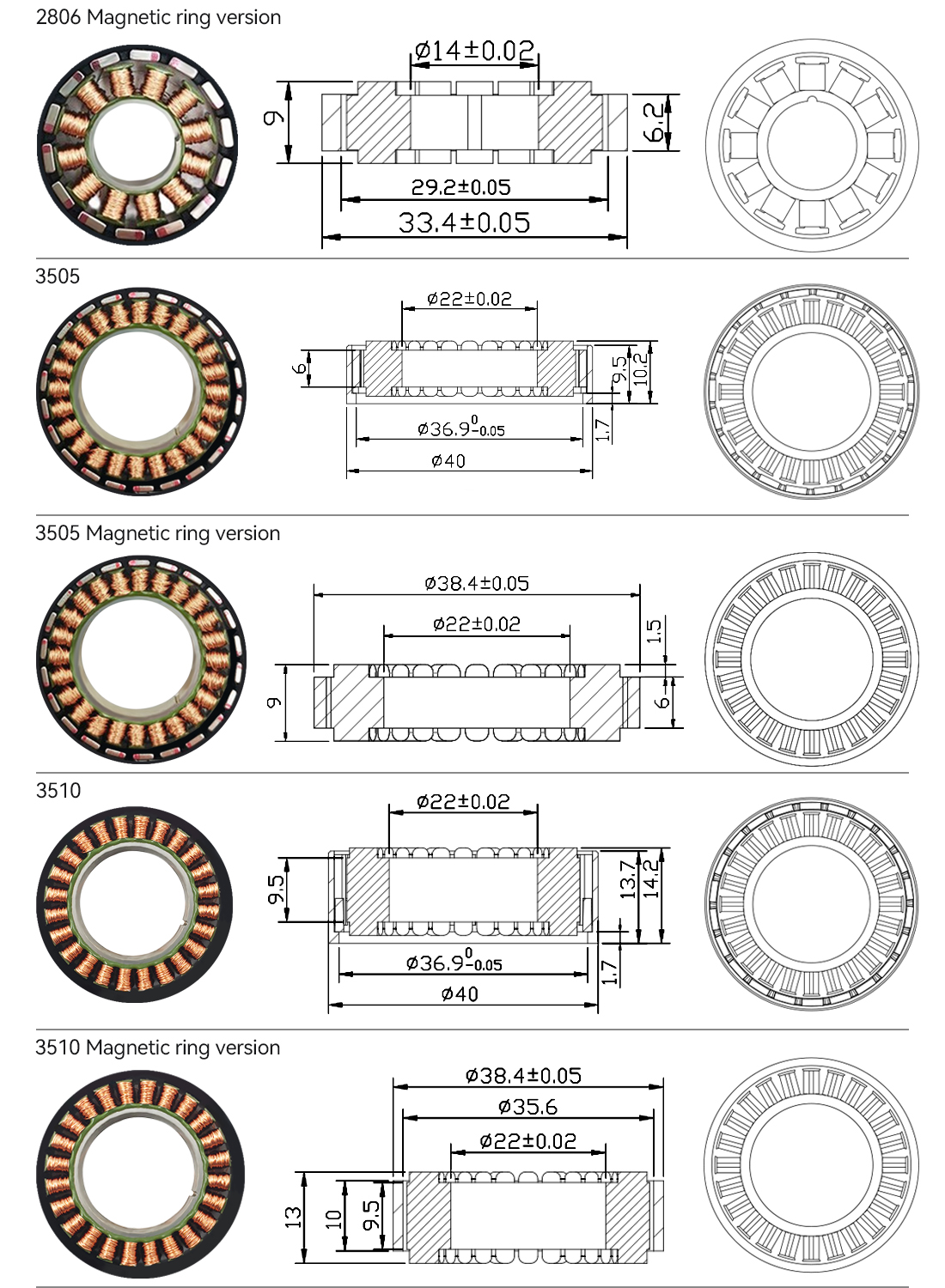

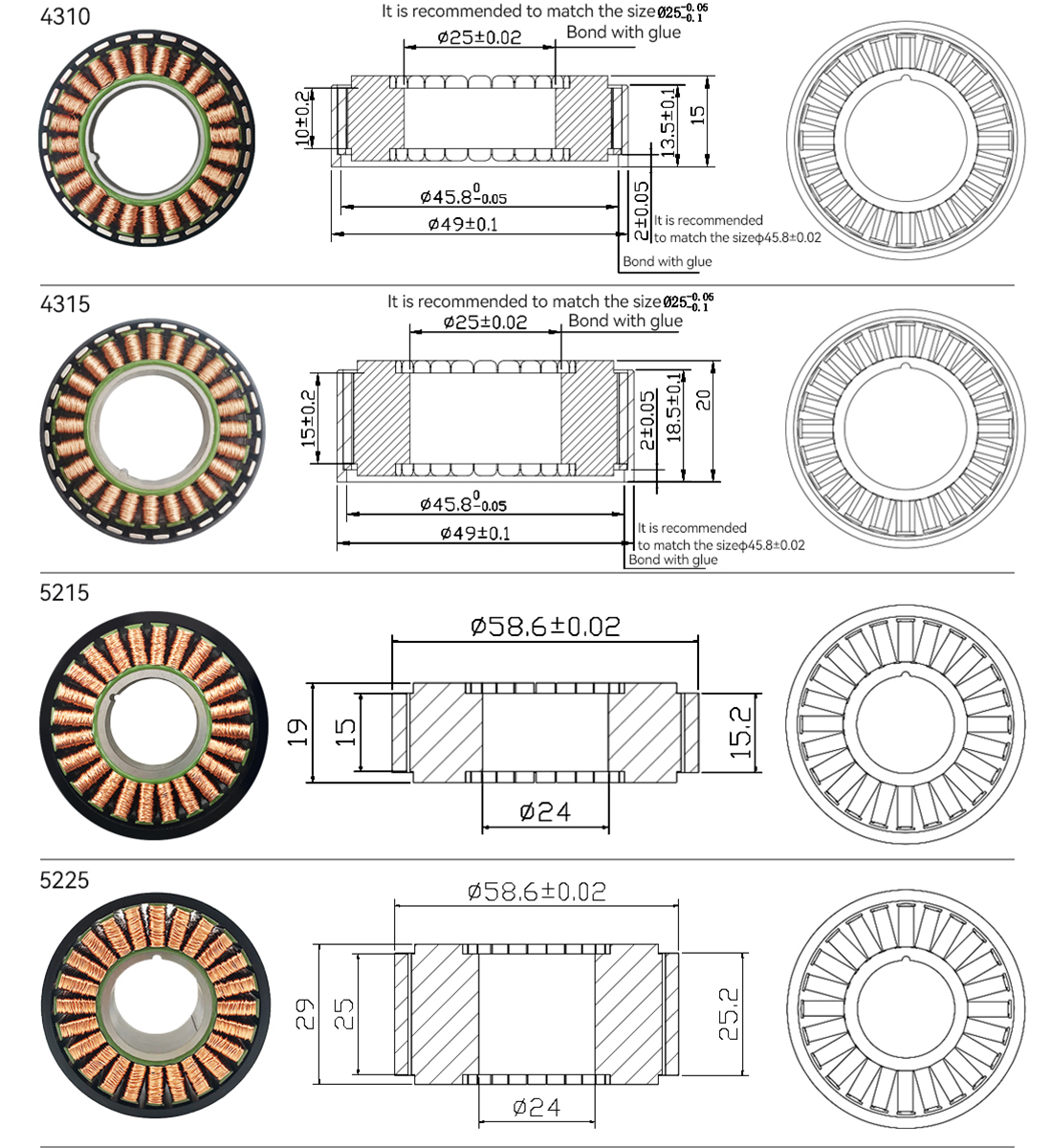

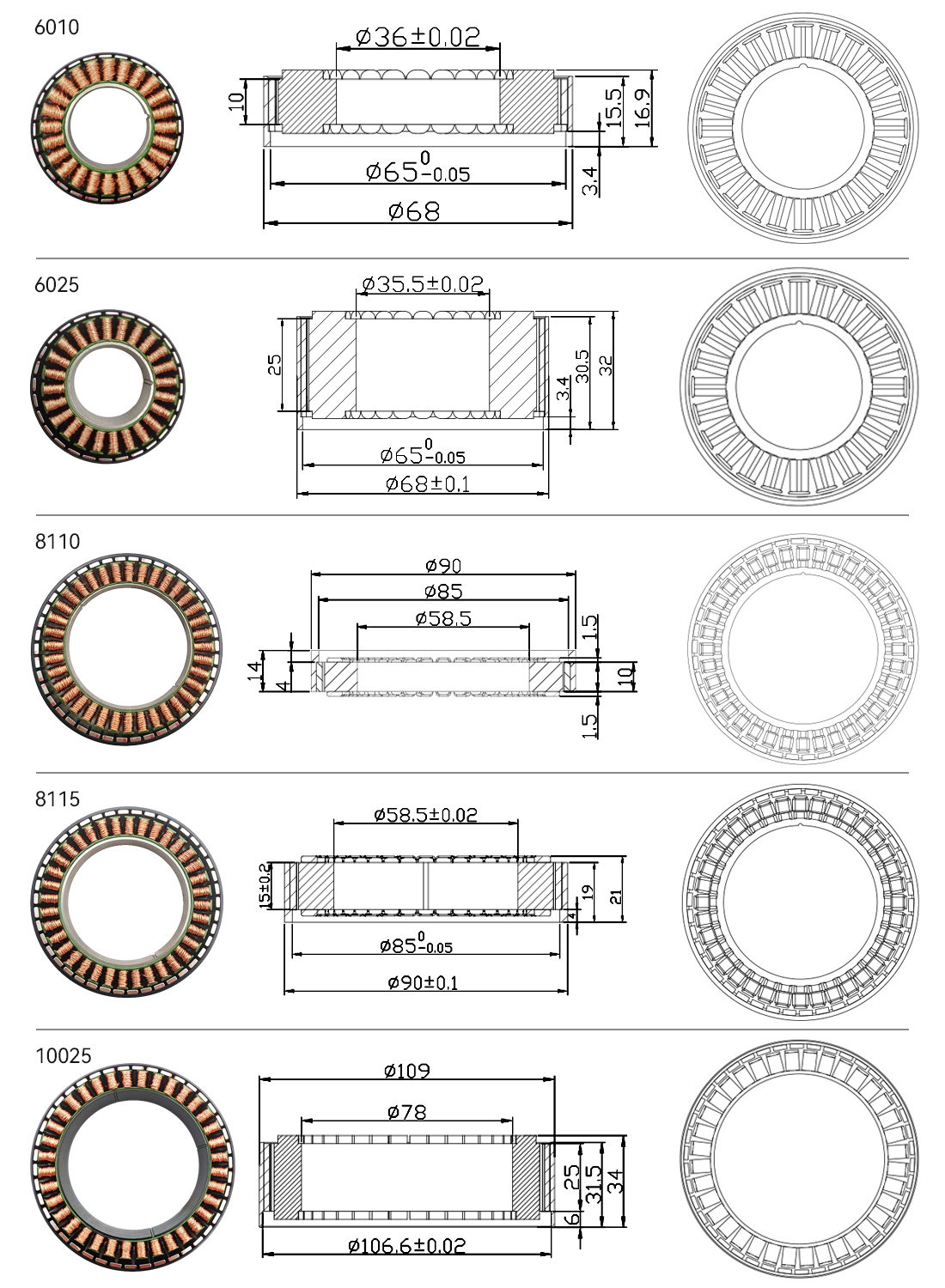

Dimensional drawing

Product parameters

Parments | Unit | WK1105CH | WK1806 | WK2205 | WK2205CH | WK2806 | WK2806CH | WK3506 | WK3506CH | WK3510 | WK3510CH |

Rated voltage | V | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

Rated current | A | 0.59 | 0.66 | 0.66 | 0.66 | 0.81 | 0.81 | 1.10 | 1.10 | 0.53 | 0.53 |

Rated torque | N.M | 0.01 | 0.03 | 0.04 | 0.02 | 0.06 | 0.03 | 0.09 | 0.05 | 0.11 | 0.06 |

Rated Speed | RPM | 850 | 800 | 792 | 792 | 950 | 950 | 467 | 467 | 363 | 363 |

Peak Speed | RPM | 18057 | 5017 | 5630 | 5630 | 2335 | 2335 | 1610 | 1610 | 965 | 965 |

Peak torque | N.M | 0.01 | 0.06 | 0.12 | 0.06 | 0.09 | 0.05 | 0.15 | 0.08 | 0.16 | 0.08 |

Peak current | A | 0.92 | 1.00 | 1.00 | 1.00 | 1.22 | 1.22 | 1.90 | 1.90 | 0.80 | 0.80 |

Winding turns of motor | T | 50 | 45 | 65 | 65 | 60 | 60 | 40 | 40 | 40 | 40 |

Interphase resistance | Ω | 12.50 | 5.64 | 7.40 | 7.40 | 5.13 | 5.13 | 6.56 | 6.56 | 8.53 | 8.53 |

Interphase inductance | mH | 1.15 | 1.06 | 1.68 | 1.68 | 1.64 | 1.64 | 1.27 | 1.27 | 1.90 | 1.90 |

Speed constant | rpm/v | 1505 | 418 | 469 | 469 | 195 | 195 | 134 | 134 | 80 | 80 |

Torque constant | N.M/A | 0.01 | 0.06 | 0.12 | 0.06 | 0.07 | 0.04 | 0.08 | 0.04 | 0.20 | 0.10 |

Rotor inertia | gcm^2 | 1 | 6 | 9 | 5 | 36 | 19 | 51 | 20 | 76 | 33 |

Number of pole pairs | Pairs | 6 | 7 | 7 | 7 | 7 | 7 | 11 | 11 | 11 | 11 |

Motor weight | g | 6 | 12 | 14 | 12 | 26 | 22 | 32 | 24 | 47 | 36 |

Working temperature | ℃ | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 |

Peak demagnetize temperature | ℃ | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

Inner diameter of the stator | mm | 5 | 9 | 10 | 10 | 14 | 14 | 22 | 22 | 22 | 22 |

Motor Size | mm | Ø14.9*6.25 | Ø22*8.5 | Ø26.3*9 | Ø25.3*6.2 | Ø34.6*9.4 | Ø33.4*66.2 | Ø40*9.5 | Ø38.4*9 | Ø40*13.7 | Ø38.4*13 |

Parments | Unit | WK4310 | WK4315 | WK5215CH | WK5225CH | WK5515 | WK6010_10 | WK6025 | WK8110 | WK8115_1 | WK8115_4 | WK10025 |

Rated voltage | V | 24 | 24 | 24 | 24 | 24 | 36 | 36 | 24 | 24 | 36 | 36 |

Rated current | A | 0.90 | 0.59 | 1.24 | 1.54 | 1.60 | 1.30 | 7.40 | 2.49 | 5.80 | 2.10 | 3.80 |

Rated torque | N.M | 0.20 | 0.28 | 0.41 | 0.57 | 0.65 | 0.80 | 1.77 | 0.93 | 1.10 | 1.26 | 4.00 |

Rated Speed | RPM | 504 | 238 | 140 | 110 | 264 | 294 | 504 | 349 | 954 | 372 | 168 |

Peak Speed | RPM | 1028 | 660 | 557 | 428 | 558 | 564 | 720 | 566 | 1146 | 534 | 330 |

Peak torque | N.M | 0.49 | 0.42 | 0.53 | 0.77 | 1.26 | 1.59 | 2.68 | 2.40 | 5.17 | 4.11 | 8.50 |

Peak current | A | 1.90 | 0.90 | 1.56 | 1.90 | 3.20 | 2.70 | 10.67 | 6.51 | 33.10 | 6.60 | 16.00 |

Winding turns of motor | T | 60 | 60 | 60 | 50 | 42 | 80 | 30 | 30 | 8 | 30 | 20 |

Interphase resistance | Ω | 10.32 | 13.84 | 14.09 | 11.36 | 5.62 | 10.28 | 3.35 | 2.29 | 0.35 | 3.81 | 3.06 |

Interphase inductance | mH | 4.76 | 6.45 | 8.98 | 10.04 | 3.98 | 12.35 | 3.73 | 2.32 | 0.25 | 3.27 | 3.03 |

Speed constant | rpm/v | 43 | 28 | 23 | 18 | 23 | 16 | 20 | 24 | 48 | 15 | 9 |

Torque constant | N.M/A | 0.23 | 0.47 | 0.35 | 0.42 | 0.43 | 0.61 | 0.23 | 0.39 | 0.19 | 0.67 | 1.03 |

Rotor inertia | gcm^2 | 161 | 223 | 338 | 561 | 456 | 514 | 1069 | 1716 | 2368 | 2368 | 6447 |

Number of pole pairs | Pairs | 14 | 14 | 11 | 11 | 14 | 14 | 14 | 21 | 21 | 21 | 21 |

Motor weight | g | 78 | 110 | 167 | 281 | 196 | 156 | 345 | 206 | 313 | 313 | 576 |

Working temperature | ℃ | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 |

Peak demagnetize temperature | ℃ | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

Inner diameter of the stator | mm | 25 | 25 | 24 | 24 | 24 | 36 | 35.5 | 58.5 | 58.5 | 58.5 | 78 |

Motor Size | mm | Ø49*13.5 | Ø49*18.5 | Ø58.6*19 | Ø58.6*29 | Ø60*19 | Ø68*15.5 | Ø68*30.5 | Ø90*14 | Ø90*19 | Ø90*19 | Ø109*33 |

Service

Dedicated service, along the way

Warranty worry-free, extended repair, often return to promote optimization, peace of mind choice, all in control.

Online customer service Efficient logistics Deliver on time Quality Assurance Technical maintenance Manufacturer support

After-sale guarantee

After-sales service: We provide comprehensive after-sales technical support, if you encounter any problems in the process of use, the professional after-sales engineer team will respond quickly, through telephone, mail or remote assistance, to provide you with detailed solutions. We also provide regular return visits to our products to understand how they are used and to collect your feedback in order to continuously optimize our products and services. In addition, in strict accordance with the quality assurance policy, we provide free repair or replacement services for products with quality problems during the warranty period, so that you have no worries.