Product Description

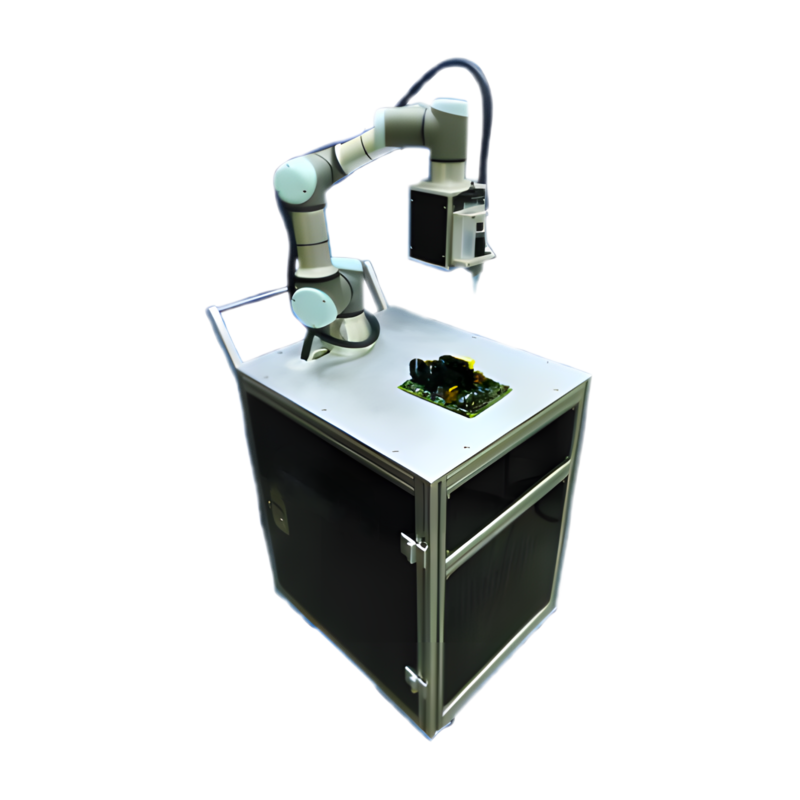

RoboFlex™ Autonomous Cobot Mobility Integration System is a cutting-edge, modular solution that enhances the flexibility, autonomy, and productivity of collaborative robots (cobots) by mounting them onto Autonomous Mobile Robots (AMRs). This integration transforms stationary robotic systems into mobile, multi-location task performers, capable of dynamically navigating complex industrial environments. With smart navigation, seamless loading/unloading automation, and advanced fleet management software, RoboFlex™ enables scalable, intelligent automation for manufacturing, warehousing, and logistics applications.

RoboFlex™ combines the dexterity of robotic arms with the mobility of AMRs to deliver end-to-end task automation across facilities, reducing reliance on human labor for repetitive and hazardous tasks while enhancing throughput, safety, and ROI.

Application

| Industry | Use Case | Benefits |

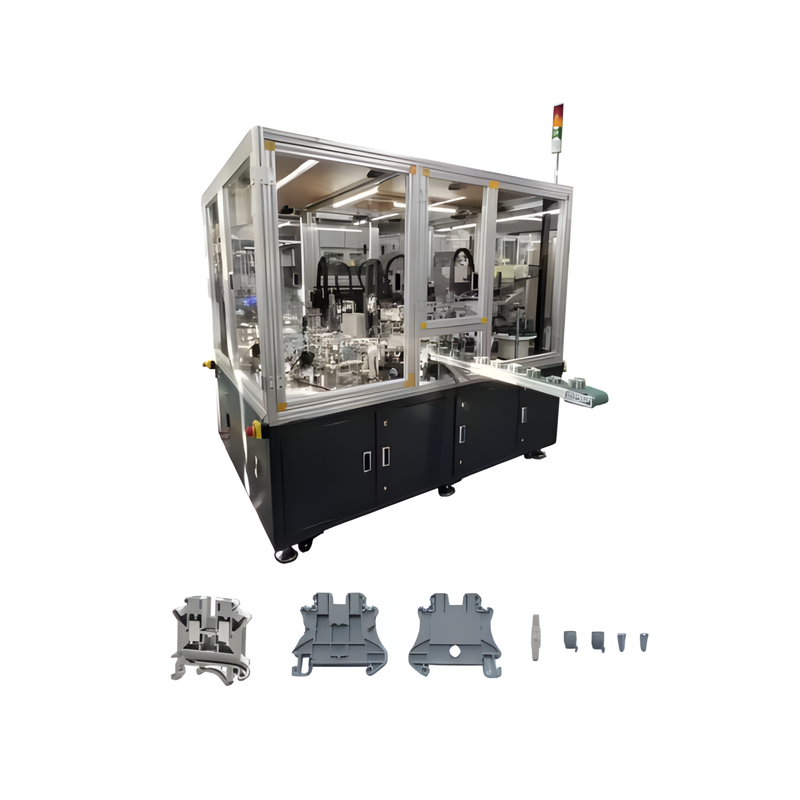

| Manufacturing | Material transfer between workstations | Reduced downtime, labor savings |

| Warehousing & Logistics | Automated loading/unloading of packages | Improved throughput, safer working environment |

| Electronics Assembly | Transporting parts to and from testing stations | Precision, time-saving, reduced errors |

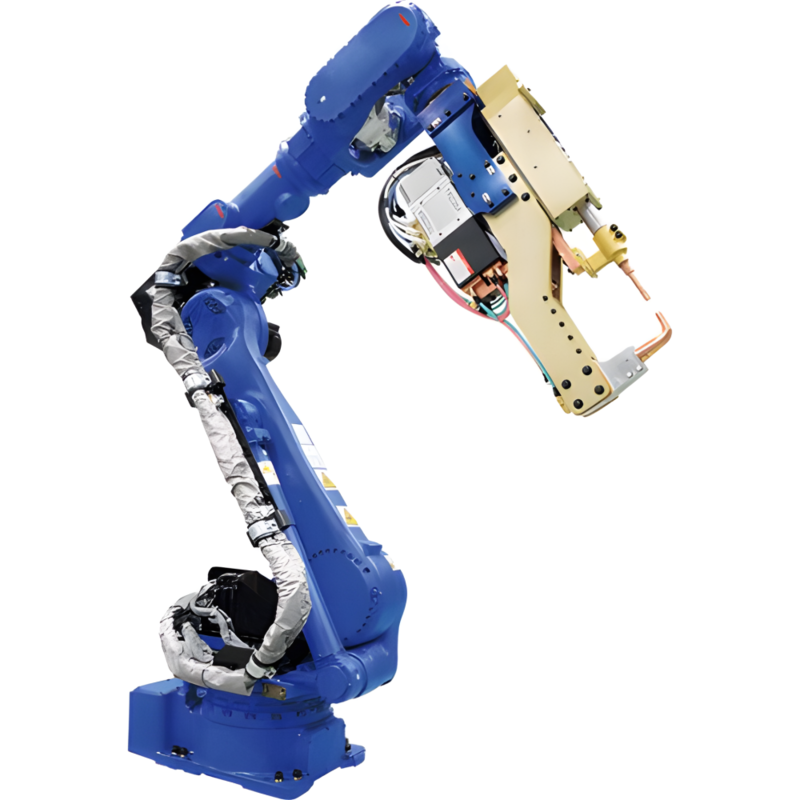

| Automotive | Moving heavy parts across assembly lines | Labor reduction, safer handling |

| Pharmaceuticals | Sterile material transfer in cleanrooms | Contamination-free transport, efficiency |

Product Features

Extended Operational Mobility with Seamless AMR Integration

Mount your cobot arm on a powerful Autonomous Mobile Robot platform to create a highly mobile automation unit. This system dynamically moves between workstations, machines, or zones without the need for human intervention or fixed infrastructure, expanding automation reach across large and complex environments.

Scalable Fleet Coordination with Advanced Management Software

Integrate multiple RoboFlex™ units with an intelligent fleet management system that allows real-time coordination, route optimization, task scheduling, and load balancing. Whether scaling up from 1 to 50+ units, RoboFlex™ ensures seamless operation and resource allocation.

Product parameters

| Specification | Details |

| Supported Cobot Models | Universal Robots UR5e, UR10e, Doosan, ABB YuMi, etc. |

| AMR Compatibility | MiR 100/200/250/600, OMRON LD, Clearpath, AgileX |

| Navigation System | SLAM-based autonomous navigation, LiDAR + vision sensors |

| Payload Capacity (Cobot + Load) | Up to 200 kg (depending on AMR platform) |

| Battery Life | 8–12 hours (swappable battery modules available) |

| Fleet Management Software | Centralized dashboard, API integration, cloud-ready |

| Safety Compliance | ISO 10218, ISO/TS 15066, CE certified |

| Communication Protocols | ROS, MQTT, OPC-UA, Ethernet/IP, Modbus |

| Docking/Charging Automation | Automatic docking and wireless charging available |

Customer Case

Automated Raw Material Supply

Packaging Line Support

Medical Supply Transport

FAQ

1. What types of cobots and AMRs are compatible with RoboFlex™?

RoboFlex™ is designed to be a modular platform compatible with a wide range of leading cobots (e.g., UR, Doosan, ABB) and AMRs (e.g., MiR, OMRON, Clearpath). Custom configurations are also available on request.

2. How does RoboFlex™ navigate dynamic environments safely?

It uses SLAM (Simultaneous Localization and Mapping) combined with LiDAR and visual sensors to detect obstacles, map the environment, and navigate safely around people and equipment.

3. Can the system operate in multi-floor or complex facilities?

Yes. RoboFlex™ can be configured to communicate with elevators and smart doors, and it includes route planning capabilities to function in complex, multi-level facilities.

4. What happens if multiple RoboFlex™ units are in the same area?

The fleet management system ensures collision avoidance, dynamic rerouting, and efficient task scheduling to avoid traffic congestion and task duplication.

5. Is the system suitable for cleanroom or ESD-sensitive environments?

Yes. Cleanroom-compatible AMRs and ESD-safe cobots can be integrated into RoboFlex™ for environments like semiconductor manufacturing and pharmaceutical labs.