T1

2 Years

T1

2 Years

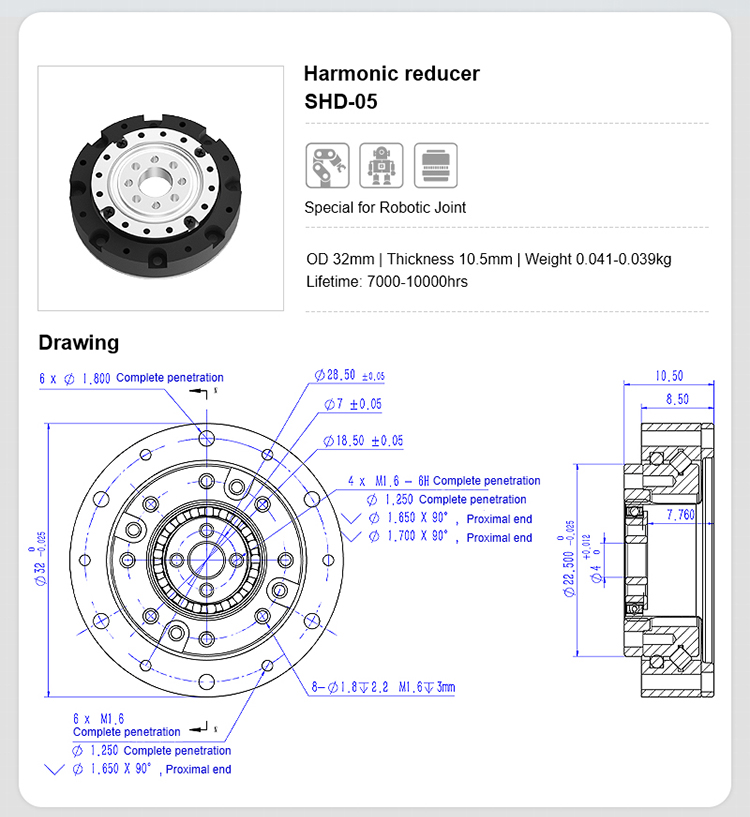

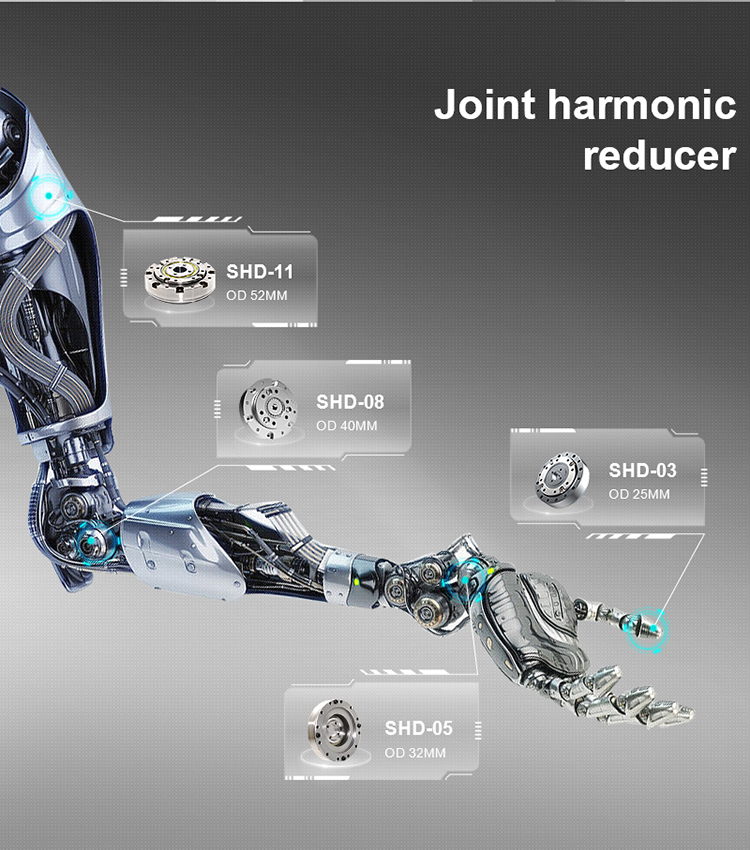

SHD-05 High Precision Harmonic Drive Small Speed Reducer

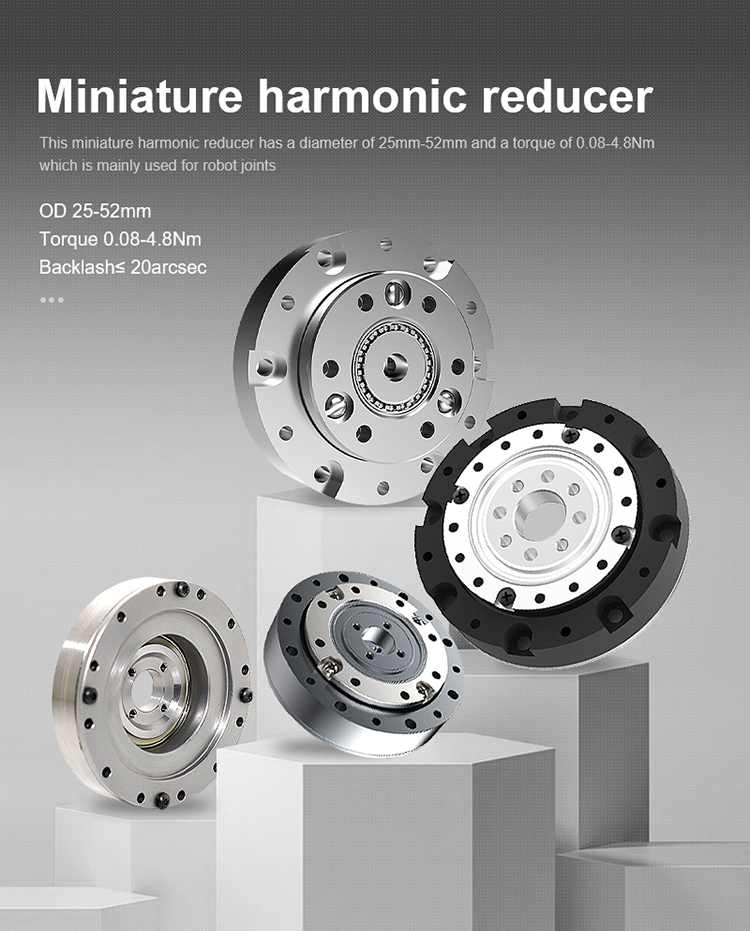

This miniature harmonic reducer has a diameter of 25mm 52mm and a torque of 0 08 4 8Nm which is mainly used for robot joints

- Reduction ratio:30/50/80

- Rated speed when input 2000r/min:0.23/0.38/0.5N.m

- Peak torque at start stop:0.47/0.87/1.2Nm

- Maximum allowable load torque on average:0.35/0.5/0.82Nm

- Maximum allowable moment torque:0.85/1.7//2.2Nm

- Backlash:20/20/10arcsec

- Allowable maximum input speed:10000rpm

- Allowable average input speed:6500rpm

USD: 195

ablity:Monthly Output100

- Penerangan Produk

- Product Params

Penerangan Produk

This miniature harmonic reducer has a diameter of 25mm-52mm and a torque of 0.08-4.8Nm, which is mainly used for robot joints.

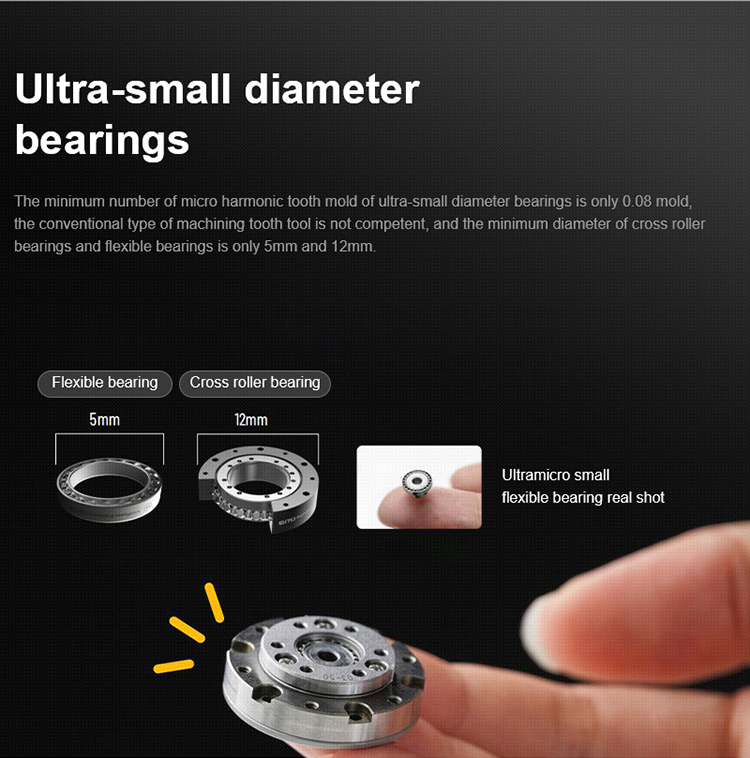

The minimum number of micro harmonic tooth mold of ultra-small diameter bearings is only 0.08 mold, the conventional type of machining tooth tool is not competent, and the minimum diameter of cross roller bearings and flexible bearings is only 5mm and 12mm.

In the production of ultra-micro cross roller bearings, different from the conventional models, the embedded separate trench structure developed and designed by us perfectly avoids the situation missing in the market of ultra-small raceway grinding machines, and solves the problem of ultra-small processing of trench grinding machines from the technical process level through the structural design.

Due to the small and thin outer diameter of ultra-flexible bearings, in order to reduce the size chain error and deformation of multiple clamping, the processing process of the conventional bearing division order cannot be followed, and it needs to be a composite processing method of the finished product. We have combined the technical team of the well-known bearing research institute in China, on the basis of the small precision composite machining center, increased the function of raceway grinding and laser heat treatment, and realized the process flow of one-time completion of the ultra-static raceway from the car -- heat treatment -- efficiently solved the production problem of ultra-small flexible bearings.

The toughness of the flex wheel

Through special electroslag remelting purification of raw materials, repeated spinning and other precision means, we improve the stability of various performance indicators of flexographic materials, ensure the harsh requirements of flexographic fatigue strength, and protect the overall mechanical structure from damage to the maximum extent through material toughness deformation under excess load.

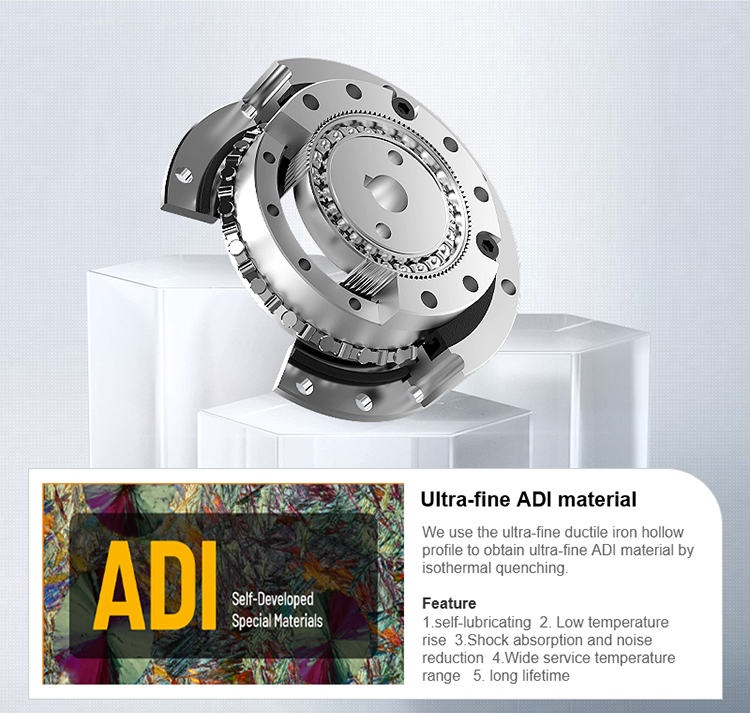

Ultra-fine ADI material

We use the ultra-fine ductile iron hollow profile to obtain ultra-fine ADI material by isothermal quenching.

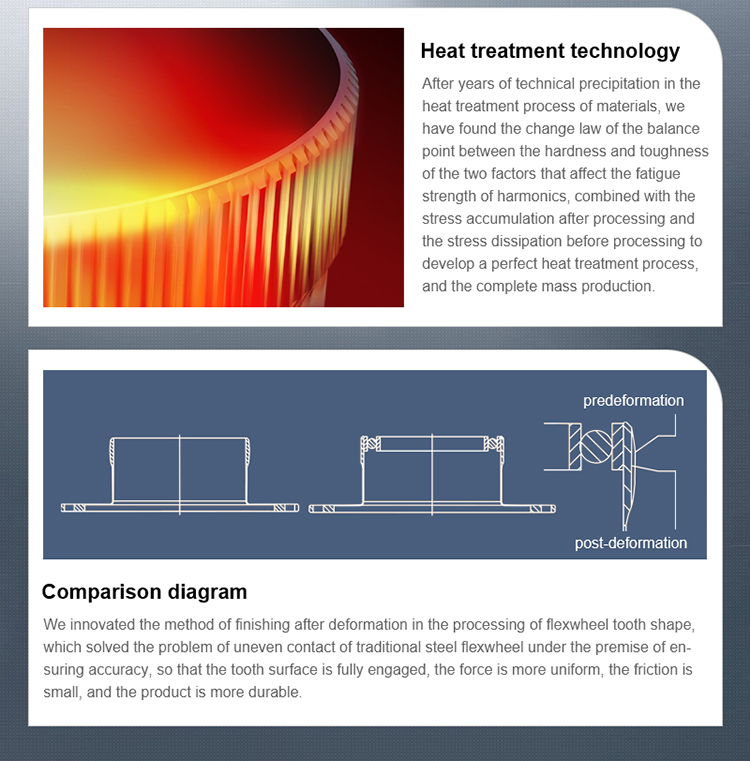

After years of technical precipitation in the heat treatment process of materials, we have found the change law of the balance point between the hardness and toughness of the two factors that affect the fatigue strength of harmonics, combined with the stress accumulation after processing and the stress dissipation before processing to develop a perfect heat treatment process, and the complete mass production.

Together with the deep Sea Silent Transmission Laboratory of the university, we invented the theory of S-shape harmonic tooth profile design on how to smoothly transfer friction and reduce the friction coefficient of cutting teeth, and designed the simulation software of automatically generating S-shape curves by combining kinematics, tribology and lubrication.