Product Description

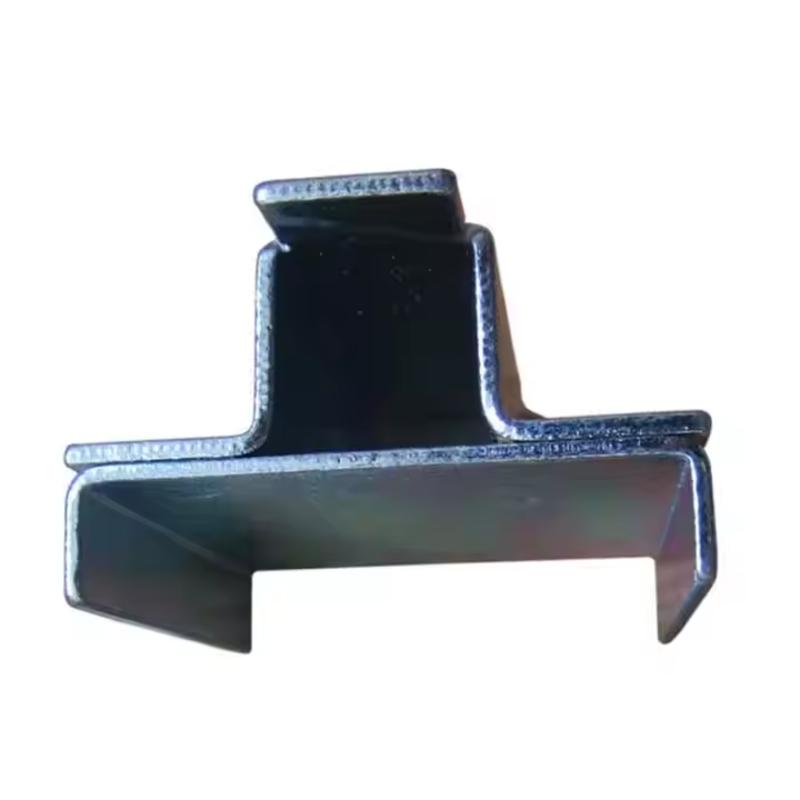

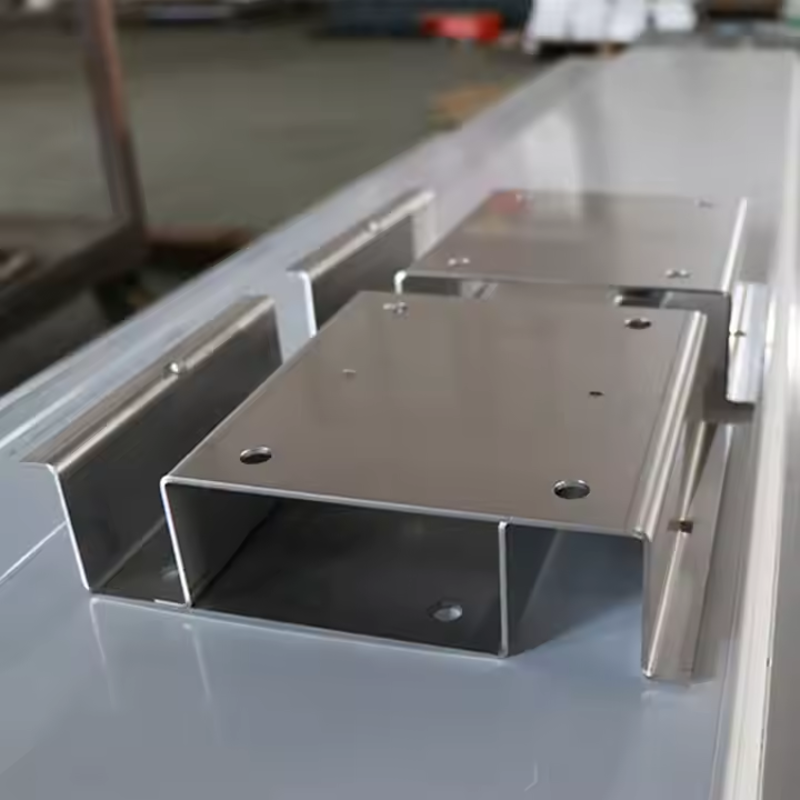

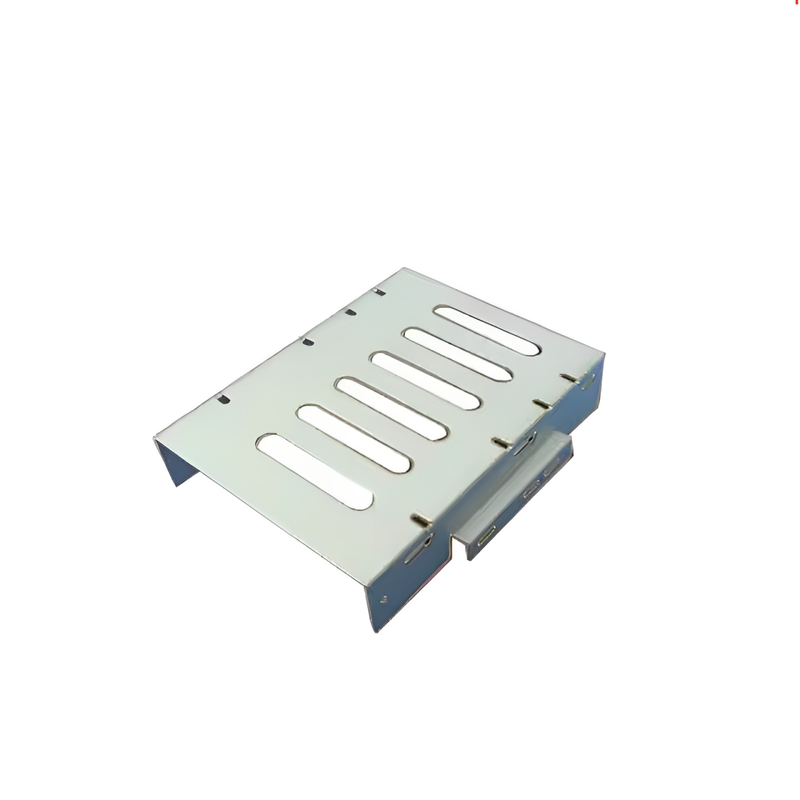

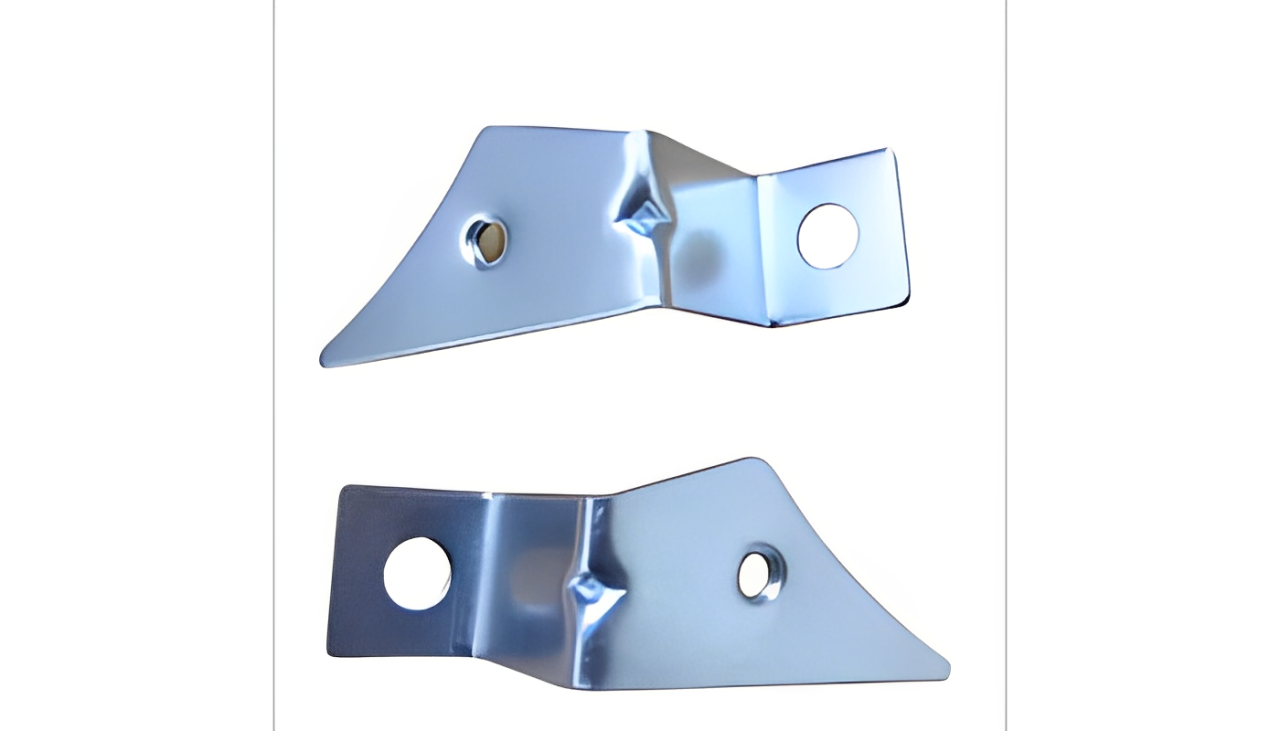

Our Custom Bending Stamping provides precision-formed metal parts tailored to your specifications. Ideal for automotive, electronics, and industrial uses, each component is crafted for accuracy and durability. With options in material, shape, and size, our service ensures high-quality, reliable parts that meet unique design and functional needs.

Product parameters

| Size | According to customer needs. |

| Sample | Free sample |

| MOQ | 100pcs |

| Delivery Time | 7-20 Days |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Agricultural Equipment

- Reason: Components in agricultural machinery, such as metal frames and connectors, need to withstand heavy-duty operations in tough environments. Custom bending stamping allows for strong, purpose-shaped parts.

Construction Equipment

- Reason: Scaffolding, metal frames, and tools used in construction require strength, load-bearing capacity, and shapes tailored to specific tasks. Custom bending stamping creates durable components that meet these demands effectively.

Communication Devices and Antennas

- Reason: Antenna frames and parts in communication devices require precision and durability for use in outdoor conditions. Metal bending and stamping produce sturdy, easy-to-assemble components.

Quality Control

Quality control in custom bending stamping ensures each part meets exact specifications and functional standards. The process includes material inspection, precise tooling checks, and dimensional accuracy verification to prevent defects. Visual and mechanical testing identify any surface flaws or structural weaknesses, while in-process monitoring maintains consistent quality. Final inspection ensures the part's durability, fit, and performance, delivering reliable components that meet customer requirements

Processing capability

The processing capability of custom bending stamping includes handling various metals and complex shapes with high precision. It accommodates diverse thicknesses and intricate bends, ensuring consistency across high-volume production. Custom bending stamping is suitable for producing parts with tight tolerances and complex geometries, meeting the demands of industries like automotive, electronics, and construction

Additional processes

Additional processes in custom bending stamping include deburring to remove sharp edges, welding to join parts, and surface treatments like painting or plating to enhance corrosion resistance and appearance. Final assembly ensures parts are ready for use, delivering high-quality components that meet specific design and durability requirements