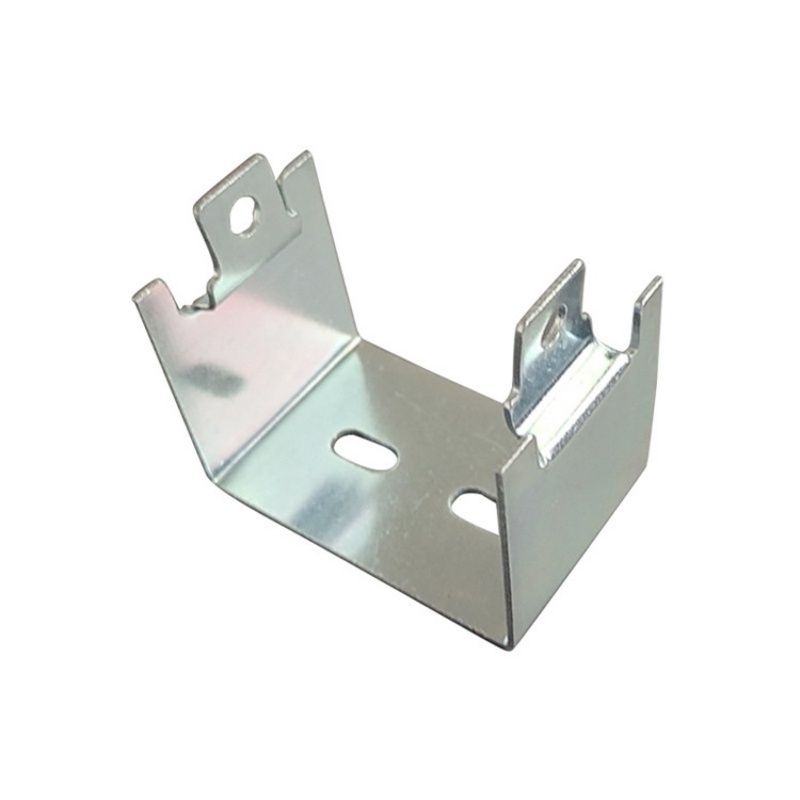

Product Description

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages.

The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined.

Stamping is usually done on cold metal sheet. See Forging for hot metal forming operations.

Product parameters

| Part Name | stamping parts |

| Materials | steel, stainless steel, brass, copper, bronze, aluminum, titanium, silicon steel, nickel plate etc... |

| Tolerance | customized |

| Thickness | 0.01-0.05mm |

| Surface Treatment | brushing, polishing, electrophoresis, anodize, powder coating, silk screen, laser engraving etc... |

Process Introduce

1. METAL STAMPING

We are a professional metal stamping and deep drawing custom metal parts manufacturer with more than 15 years of experience, equipped with precision power press, machining accuracy up to 0.01mm. We are equipped to manufacturer metal stamping dies and stamp metal parts production according to customer’s drawings or samples.

2. STAMPING DIE/ MOULD DEVELOPMENT

Our company specializes in stamping die and mould design, manufacturing and processing over 15 yearsexperience. We can help with your metal stamping die/ mould development from ideas to a product and manufacturer single die or progressive die according to customer’s order quantity and requirements.

3. SHEET METAL FABRICATION

Except metal stamping, we also offer the most cost-effective way to your project according to customer’s order quantity, we can use laser cutting, CNC punching and CNC bending automatic production. We can cut all kinds of sheet metal and tube & pipe accurately with a wide range of thickness up to 30mm.

4. ASSEMBLE & SURFACE TREATMENT

We are equipped with welding machine and riveting machine, which can help us assemble different parts according to customer’s drawing and requirements. We provide various surface treatment according to customer’s request, such as Power Coating, Plating, Electrophoresis, Anodized, Brushing, Polishing and so on.

Product Display

Stamping is a manufacturing process that can be used with many different materials, including metals such as steel, aluminum, brass, and copper; composite plastics; or other special types of materials. It depends largely on what you want the finished product to look like: whether it's hardy yet malleable enough or whether it has all the qualities you need when pressing it into certain shapes. In most cases though - metal remains the primary material because it withstands pressure while remaining malleable enough to form various shapes without breaking.

Metal Stamping parts are pieces of metal that are shaped by applying an intense force through a die. Metal blanks are inserted into dies and then pressed to create specific shapes. Commonly stamped items include car body panels, engine components, and household appliances.

Application Cases

Production process

Design review and quote

Initial feasibility study and quote for customer review and confirmation

Confirmation

DFM for customer review and confirmation

Tooling/ moulding

Machine adjustment and sample making

Sample review & confirmation

Sample sent to customer to review and confirm for production

Inspection and packaging

100% part inspection before delivery

Cooperative partner

FAQ

How can i get a quotation from your company?

Contact us. In order to quote you as soon as possible, we need the following information:

1:Detailed drawings(Format:CAD/PDF/DWG/DXF/DXW/IGES/STEP ETC...)

2:Material

3:Quantity

4:Surface treatment

5:Any special pacaking or other requirement

What's the MOQ?

We can accept low quantity.

Can I get a sample for check?

Yes ,Just need sample cost,we will return it back in mass production

What if want custom a part but I Can't draw?

We can also offer design service as long as you tell us all your requires.

I want to keep our design in secret,can we sign NDA?

Sure ,we can sign NDA before you send the drawing.

What's the leading time?

It depends on quantity,Generally 7-20 days after order confirmation.