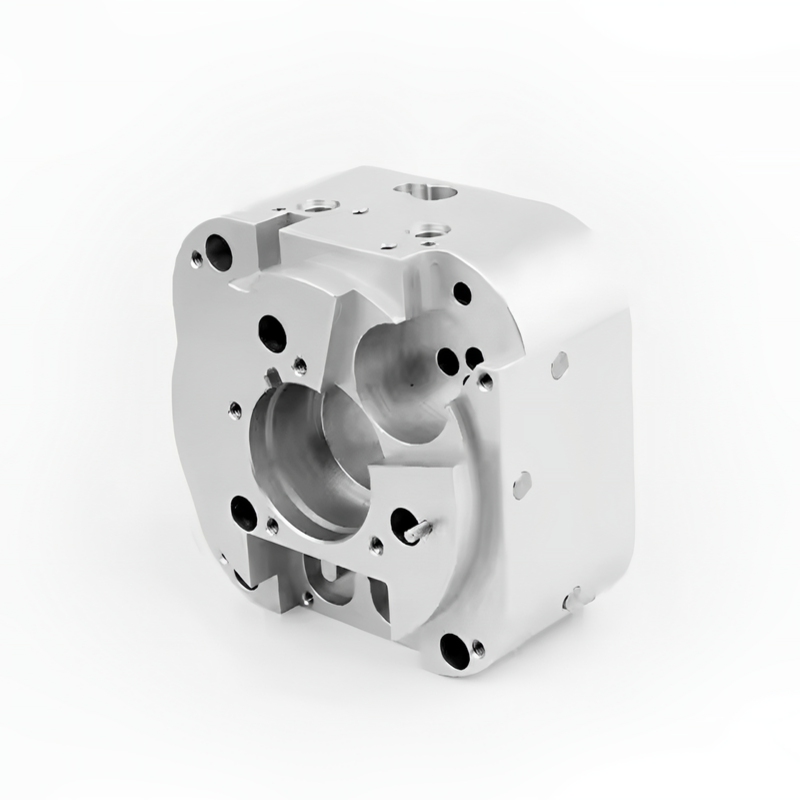

Product Description

This precision-engineered brass component features a multi-threaded design and robust structure, ensuring secure fittings and long-lasting durability. Ideal for industrial machinery and equipment requiring reliable, high-performance parts.

Product parameters

| Business Type | Factory / Manufacturer |

| Service | CNC Machining Turning and Milling CNC Turning OEM Parts |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc 3). Steel: 4140, Q235, Q345B,20#,45# etc. 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc 6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm CNC milling work range: 510mm*1020mm*500mm |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Mining and Drilling Machinery

Brass components are used in mining and drilling machinery due to their wear resistance and ability to withstand humid or chemically challenging environments.

Hydraulic Machines

In hydraulic systems, brass components are used as connectors or adapters due to their ability to withstand high pressure and ensure tight sealing. This reduces leakage and improves system efficiency.

Automotive Radiators

Brass components are ideal for automotive radiators due to their heat dissipation properties and corrosion resistance, which enhance the efficiency and longevity of cooling systems.

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

Quality control for CNC machined parts, such as components used in electrical devices and other machinery, involves checking material quality, ensuring dimensional accuracy, and inspecting surface finishes for defects. The parts must undergo performance testing for heat resistance and durability. Electrical connections and safety standards must be verified to prevent hazards. Waterproof and dustproof testing is essential, and the packaging should protect the parts during transportation.

Processing capability

Processing capability for CNC machined parts refers to the facility's ability to handle various materials, sizes, and complexities with high precision. It includes machining complex designs, managing different production volumes, and performing post-processing operations like polishing or coating. Automation and efficiency ensure consistent quality and higher throughput, allowing the facility to meet specific production needs

Additional processes

Additional processes in CNC machining include grinding, heat treatment, polishing, coating, welding, assembly, and laser engraving. These operations are used to enhance the surface finish, improve material strength, add protective coatings, join parts, and ensure proper assembly. Polishing and coating improve appearance and durability, while heat treatment alters material properties for better performance. Laser engraving provides identification or branding, and welding and assembly are crucial for combining parts into a finished product. These processes ensure that the parts meet both functional and aesthetic requirements.