Product Description

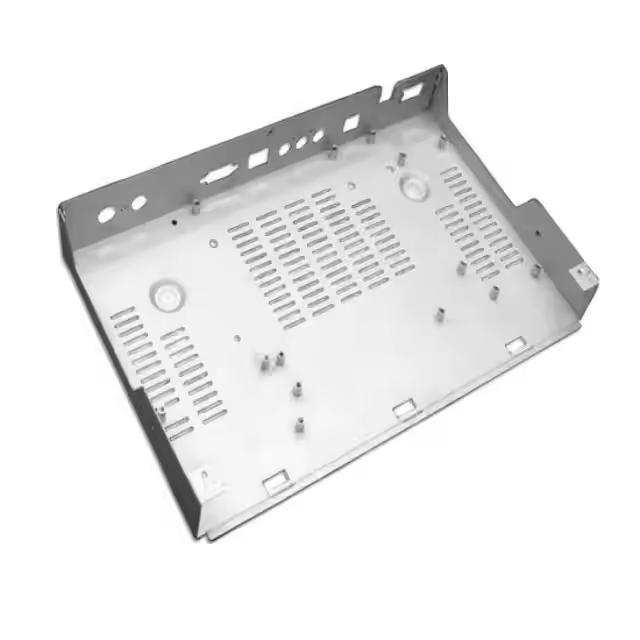

Sheet metal works involve shaping and forming metal sheets into various components through processes like cutting, bending, and welding. It is used in industries such as automotive, construction, and electronics for strong, precise part

Product parameters

| Metal Material | commonly used: Steel / Stainless Steel / Aluminum Special: Channel steel / H-beam / U-beam / Angle steel,etc. |

| Drawing format | STEP STP DXF DWG |

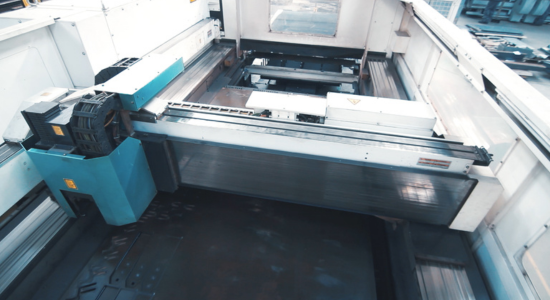

| Processing | Laser Cutting Stamping Punching Bending Manual welding Machine welding Deburring |

| Finishing | Powder coating Spraying Sanding Silk screen printing Laser marking Electro galvanized Hot-dip galvanizing |

| Tolerance | CNC equipment: 0.2mm Other equipment: 1mm |

| Expertise in products | Antenna bracket: Outdoor communication equipment mounting parts Tower traction ground anchor: Traction anchor for the outdoor power supply tower Cabinets Lithium battery cabinets Computer server cabinets Structural steel buildings structural assemble structural steel Outdoor gazebo Assemble structural steel |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Tool Storage Cabinets

Sheet metal is used in the production of tool storage cabinets and equipment that need to withstand heavy usage in factories or work environments with challenging conditions, such as high dust or humidity. Sheet metal provides strength, durability, and impact resistance, making the cabinets long-lasting and capable of protecting tools from damage

Agricultural Equipment

Agricultural tools such as tractors and heavy-duty farming machinery require materials that are strong, durable, and able to handle harsh working environments, such as muddy fields or rapidly changing weather conditions. Sheet metal provides the necessary toughness and can resist wear and tear from impacts and friction

Solar Panels

Sheet metal is used for creating frames for solar panels due to its durability and ability to protect the solar panels from harsh weather conditions or corrosion from moisture. The sheet metal helps ensure that the panels are stable and extends their lifespan, making it suitable for outdoor use

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality control in sheet metal works is crucial to ensure that all components meet strict industry standards and customer requirements. It involves inspecting materials for dimensional accuracy, surface finish, and structural integrity. The process includes tests for strength, durability, and resistance to corrosion, ensuring that the final product performs reliably in its intended application. This meticulous quality control ensures that sheet metal parts are defect-free, safe, and function efficiently, whether used in automotive, electronics, or construction industries.

Processing capability

The processing capability of sheet metal works includes a range of techniques such as precision cutting, bending, punching, and welding. These methods allow for the creation of complex and customized parts with high accuracy and strength. The versatility of these processes makes sheet metal suitable for various industries, including automotive, construction, and electronics, ensuring the production of durable and high-quality components.

Additional processes

Additional processes in sheet metal works include surface treatments such as coating, painting, and anodizing, which enhance corrosion resistance and appearance. Other processes like perforating, embossing, and stamping are used to add functionality and design features, making sheet metal products more versatile and suited for a wide range of applications.