Product Description

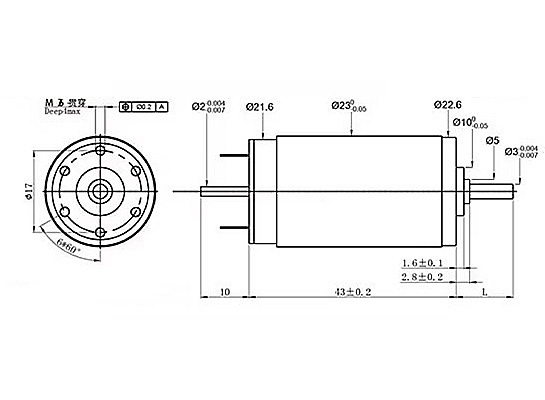

Housing and dimensions

The motor housing is a carefully designed metal material, and its compact size of 23mm in diameter and 42mm in length makes it a unique advantage in many application scenarios. The metal shell not only provides a reliable protective barrier for the internal precision structure, effectively prevents the damage of the external environment to the motor, but also has good heat dissipation performance. It is like putting on a strong and well-dissipated "armor" for the motor to ensure that the motor remains stable during long-term operation.

Product parameters

| Motor parameter | Motor type | ||||

|---|---|---|---|---|---|

| name | unit | XBD23420 6082HJ- 30065 | XBD23421 2082HJ- 30065 | XBD34218 080HJ- 30080 | XBD23422 4090HJ- 30065 |

| Rated voltage | V/DC | 6 | 12 | 18 | 24 |

| Rated speed | rpm | 7298 | 7298 | 7120 | 8010 |

| Rated current | A | 0.82 | 0.78 | 0.48 | 0.37 |

| Rated torque | mi | 5.1 | 9.96 | 8.96 | 8.38 |

| No-load speed | rpm | 8200 | 8200 | 8000 | 9000 |

| No-load current | mA | 80 | 60 | 55 | 35 |

| Maximum efficiency | % | 79.5 | 81.8 | 77.7 | 79.8 |

| Rotational speed | rpm | 7380 | 7503 | 7160 | 8145 |

| Electric current | A | 0.752 | 0.616 | 0.459 | 0.322 |

| torque | mNm | ACO | 7.7 | 8.6 | 7.2 |

| Maximum power | W | 10 | 19.4 | 17.1 | 17.9 |

| Rotational speed | rpm | 4100 | 4100 | 4000 | 4500 |

| Electric current | A | 3.4 | 3.3 | 2 | 1.5 |

| torque | mNm | 23.2 | 45.3 | 40.7 | 38.1 |

| Locked-rotor current | A | 6.8 | 6.6 | 3.9 | 3.06 |

| Locked-rotor moment | mNm | 46.4 | 90.6 | 81.4 | 76.1 |

| Motor impedance | Ω | 0.88 | 1.82 | 4.62 | 7.84 |

| Inductive reactance of motor | mH | 0.14 | 0.62 | 0.16 | 0.52 |

| Torque constant | mNm/A | 6.91 | 13.85 | 21.18 | 25.17 |

| Speed constant | rpm/V | 1366.7 | 683.3 | 444.4 | 375 |

| Revolution/torque constant | rpm/mNm | 176.7 | 90.5 | 98.2 | 118.2 |

| Mechanical time constant | ms | 9.65 | 5.91 | 5.74 | 5.89 |

| Rotor inertia | gcm2 | 5.22 | 6.24 | 5.58 | 4.76 |

Technological Innovation

Advantage of customization

The custom nature of this motor allows it to be adapted to the specific needs of the customer. Whether it is the performance parameters of the motor, such as speed range, torque requirements, or the installation of the motor, interface design, we can provide customers with tailor-made solutions. It's like creating a unique key for each customer, opening the door to applications that meet their unique needs.

Product Display

High quality operation

The custom process guarantees the high quality of the motor. The coreless structure fundamentally reduces the hysteresis loss and eddy current loss, and greatly improves the operating efficiency of the motor. This means that driven by 6V voltage, the motor can convert electrical energy into mechanical energy more effectively, providing strong power for the equipment at the same time, reducing energy consumption, achieving the perfect combination of performance and energy saving.

Precise control performance

The low inductance design of the motor winding makes its current response extremely fast, resulting in excellent speed control and position control. This feature is like installing a precise "brain" to the motor, which can achieve high-precision motion control according to external control signals, and meet the strict requirements for motor control accuracy in various complex application scenarios.

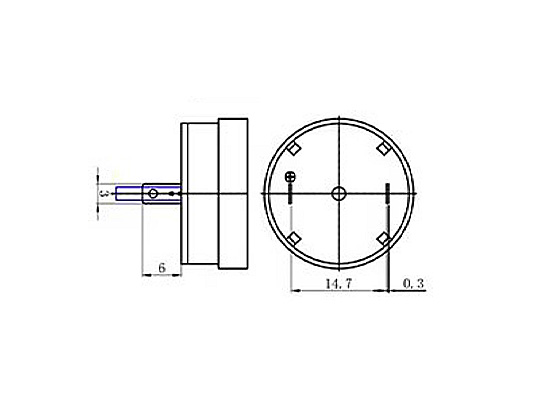

Size & Interface

Quality Control

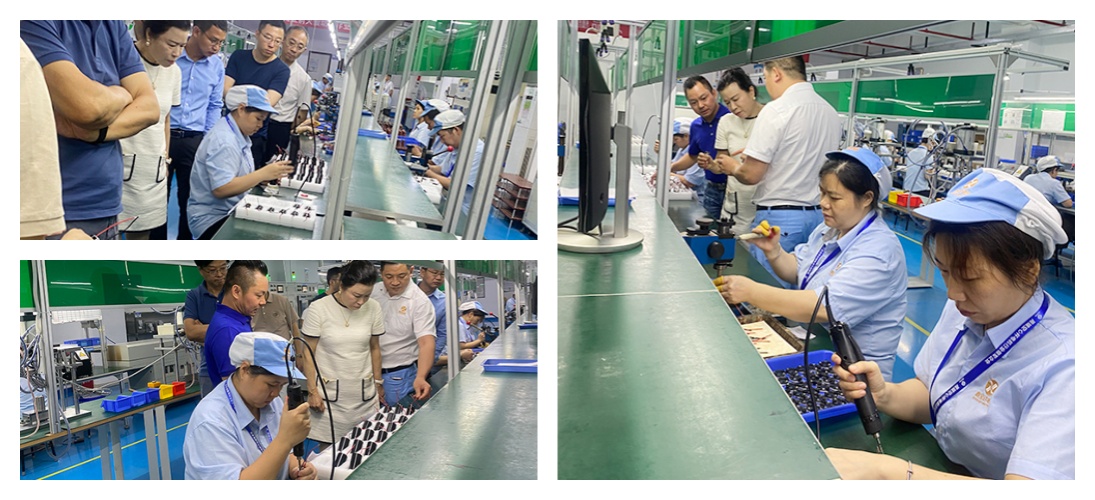

Assembly link control: tight seam

The assembly process of the motor is like a precise jigsaw puzzle, where every component must be fitted into place without error. Our assembly workers are professionally trained, have rich experience and a high sense of responsibility. When assembling the hollow cup rotor, ensure that its position in the stator is accurate and the clearance with the brush and commutator is just right. The tightening torque of each screw is precisely calculated and strictly controlled to prevent the overall performance of the motor from being too tight or too loose. After the assembly is completed, the appearance of the motor is also carefully checked to ensure that no parts are loose, scratched or improperly assembled.

Performance testing: Comprehensive inspection

We have a set of perfect performance testing system, for each hollow cup brush motor for comprehensive and strict inspection. In terms of electrical performance detection, the starting current, no-load current, rated power, speed and torque of the motor are measured by high-precision test equipment to ensure that these parameters are within the specified tolerance range and meet the design requirements. For the mechanical properties of the motor, we simulate the actual working environment and carry out long-term operating tests to observe the vibration, noise level and heating degree of the motor. Only motors that are fully qualified in all performance indicators will be labeled as qualified in quality and enter the market.

Durability test

In order to ensure the reliability and life of the motor, we will carry out a long time durability test on the motor. In the simulation of various actual working conditions, the motor is continuously run for hundreds of hours, during which the performance indicators of the motor are continuously monitored, such as temperature changes, vibration conditions, electrical parameter stability, etc. Only motors that pass the durability test and have no significant degradation in performance will be considered qualified products.

Quality traceability system: Tracing to the source

In order to ensure the continuous stability of quality, we have established a sound quality traceability system. Each hollow cup brush motor has a unique identity, from the procurement batch of raw materials, all aspects of the production process data to the final test report, are recorded in detail. Once a quality problem is found, it can be quickly traced back to the root of the problem, and effective corrective measures can be taken to avoid the recurrence of similar problems.

Application Cases

Industrial automation field

In automated production lines, the motor can be used as a precise drive unit to control the movement of small robotic arms, precise push in material handling systems, and more. Its high precision control and speed regulation performance can meet the strict requirements of precise operation in industrial environments.

Medical device application

In medical instruments, such as small diagnostic equipment and precision treatment instruments, the low noise and precise control characteristics of the motor are crucial. It can provide stable and reliable power to these devices, ensuring the accuracy of medical operations and the comfort of patients.

High-end electronic equipment field

For some high-end electronic equipment, such as precision optical instruments, high-end audio equipment in the mechanical transmission part, the high quality and customized characteristics of this motor can meet their special performance requirements, providing a strong guarantee for the high performance of the equipment.

Cooperative partner

Service

Pre-sale service

Our dedicated sales team and technical experts know everything about motors. Before you buy, you will learn more about your application needs in industrial equipment such as winding machines, industrial saws, robotic arms or automatic weighing systems. According to these requirements, we will accurately introduce the performance parameters, advantages and how to perfectly fit your equipment. Whether it is about the motor's coreless brushless design features, 36V voltage adaptability, or speed torque and other performance questions, we can give clear and professional answers, so that you have a comprehensive understanding of the product before buying.

In-sale service

During the purchase process, we guarantee the convenience and security of the transaction. Each motor is rigorously tested and carefully packaged to ensure no damage during transportation. We work with quality logistics to deliver the motor to you in an accurate and timely manner. If there is any problem after receiving the motor, our customer service team will respond quickly and actively solve.

After-sales service

Installation Guide: Provides detailed installation guides, including text, pictures and videos, to guide you in installing the motor into industrial equipment. In case of difficulties, professional engineers can provide remote guidance to ensure smooth installation.

Use training: Provide your operators with use training, covering motor start-up, operation parameter adjustment, daily operation precautions, etc., to help them give full play to the motor performance and ensure the normal operation of the equipment.

Continuous support: We pay close attention to your experience and visit regularly to collect feedback. When you have new needs or improvement suggestions, we will be happy to serve you to ensure that your industrial production continues to be efficient.